Knife gate valves (KGVs) were introduced to the world in 1927 for use in the pulp and paper industry. When the market demanded an economical valve for cellulose production, the special guillotine project was born. Since then, knife pushers have been used in several variations around the world; the push-through guillotine was introduced in the USA, while the guided guillotine was developed in Switzerland. While we have adopted the word “knife gate” as a general term for all versions of this valve, you may be surprised to learn that only the guided shear gate and its larger gauge variant can actually “cut” media like a knife. .

In this article, we will describe and understand how the gate valve works, distinguish it from other gate valves, and explain its strengths and weaknesses.

Gate valve

What is a gate valve?

Knife gate valves are specifically designed for on/off and shut-off operations in systems with a high proportion of dissolved solid particles. Gate valves are extremely useful in handling slurries, abrasive, corrosive and viscous media. The valves have a low pressure drop in the fully open position, are easy to operate, light and inexpensive.

Knife gate valves are designed for use in the harshest conditions and feature a sharp blade to cut through heavy liquids.

They are extremely useful in wastewater applications where corrosion is a major concern. In addition to the valve design optimized for sludge media, a gate valve made of acid-resistant stainless steel is advantageous because it is less susceptible to corrosion damage and therefore requires less frequent maintenance or even replacement.

Gate valves should always be used for applications that require a fully open or fully closed position and should not be used to regulate flow unless they are specifically designed for this purpose. When fluid is forced against a partially closed slide, it creates a vibration that gradually wears the disc and seat. Additionally, gate valves are designed to open and close slowly to protect against the effects of water hammer.

Classification of knife pushers.

-

According to the body material.

Gate valves are made from a variety of materials. Examples of commonly used materials include cast carbon steel, cast iron, nodular iron, bronze, nickel, alloy steel, stainless steel, and forged steel. The material used in valves is primarily determined by fluid usage and design temperature.

- Carbon steel gate valve is a robust material with high hardness, tensile strength and impact resistance. It is widely used in industrial equipment for high temperature/high pressure operations.

- Despite high costs, stainless steel gate valve has higher corrosion resistance, heat resistance, cold resistance and mechanical strength.

- Lined valves are naturally thermally stable, chemically resistant and have excellent mechanical properties. Due to its excellent processability, it is possible to provide wet valve parts with a thin coating without fear of punctures. It is also recommended for food processing because it is colorless and does not require additives or pigments.

-

By connection type.

- The final connection of the valve is mainly determined by the requirements and suitability of the valve, such as: b. Gate valve in wafer design and knife pusher with attachment are used with cheaper valves, Flanged version end is the most common of all types and a gasket is used to seal it.

Knife slider with eyelet

-

By sealing method. Metal seat/elastic seat

- Before the introduction of soft seal gate valve Gate valve with metal seat plate were often used. To ensure a tight seal, the tapered wedge design and square sealing devices of a metal-seated wedge require a recess in the valve base. Sand and stones still remain trapped in the hole. No matter how well the pipe is flushed during installation or repair, the piping system will never be completely free of contaminants. As a result, any metal wedge would lose its ability to be watertight over time.

- The resiliently seated gate valve has a simple valve base that allows sand and gravel to pass through the valve unimpeded. If contaminants pass through the valve when it closes, the rubber surface may close around the contaminants. When the valve is closed, a high-quality rubber compound captures contaminants that are removed when the valve is opened again. The rubber surface returns to its original shape, creating a tight seal.

-

By root structure. Rising stem/non-rising stem

- Knife gate valves are controlled by a threaded spindle that connects the drive (manual or motor) to the gate valve. They are classified into rising and non-rising spindles depending on which end of the spindle has a thread.

- Rising tribes are attached to the gate and rise and fall together when the valve is operated, providing a visual indication of the valve position. The nut-shaped unit rotates around the threaded shaft to raise or lower it.

- The non-rising stem valves are threaded into the slide end and connect and rotate with the actuator. Because the slide movement is hidden inside the valve, they are often equipped with a pointer screwed into the top of the stem to indicate the position of the valve. Non-rising wells are used underground or in locations where vertical space is limited.

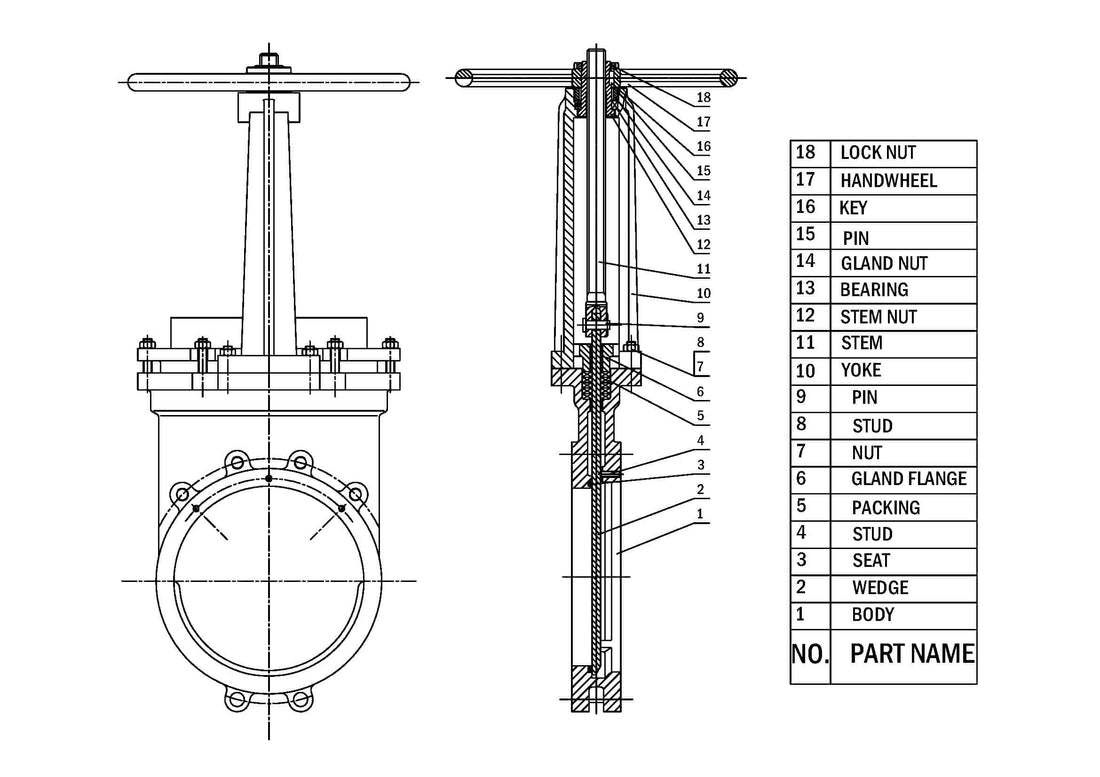

How does a knife valve work?

A gate valve is a component that uses a blade to cut through heavy fluid blockages. These sliders are designed to operate in the world's most corrosive and abrasive conditions.

Due to their highly effective design, gate valves have become essential in applications involving viscous liquids, slurries and other systems where an impingement problem exists.

Gate valves are used in many processing plants today and are available in large sizes to accommodate high-density flows of light grease, heavy oil, paint, sludge, wastewater and paper pulp. It should be noted that these valves have low pressure limitations and are designed to place the blade in an elastomeric seal after the blade has cut through the substances being processed. When a solid mass or powder flows through the gate valve, the thick, dry material is forced into the soft seals at the end of the gate valve. When this happens, the seals eventually no longer close tight enough. In this case, the seals must be replaced.

Features and benefits of the gate valve.

Gate valves are full-port valves that allow liquids of any viscosity to pass easily and there are no voids below the gate for collecting the medium. The valves are self-cleaning because particles are moved away from the slide when the valve is opened. For additional protection of the stuffing box, sliding wipers and baffle cones for impure or abrasive media can be provided. Additionally, the upper stuffing box is usually replaceable, allowing the seal to be replaced without disassembling the valve.

Knife gate valves have a simple design that allows for easy maintenance and economical installation. These valves can be bidirectional, allowing installation without flow direction restrictions. A protected seal, high-quality materials and a smooth, continuous bore guarantee excellent performance and long service life.

Knife valve maintenance manual.

As already explained, gate valves are used in numerous isolation applications. They are one of the simplest valve designs, and because they only have one moving part, preventive maintenance is quick and easy to perform.

- Make adjustments to the packaging once a month.

- Lubricate the spindle and spindle nut every 3 months. This can be done by using a grease fitting on the grease fitting on the top of the fork.

- Also, lubricate the transmission regulator once a year.

What is the difference between a gate valve and a gate valve?

The main difference is in the types of applications or media these two valves can support. Knife point valves can handle pastes, powders or granules much more efficiently than gate valves, which require transparent media to function properly. Secondly, gate valves are not designed to handle high viscosity media, while gate valves are suitable.

Another difference between gate valves and knife gate valves is that knife gate valves are designed as per ANSI standards while knife gate valves are manufactured as per TAPPI standards. Gate valves are bidirectional, commonly used in fluid applications and have only metal seats.

Another difference between a knife gate valve and a knife gate valve is the stuffing box. A V-ring seal on a slider seals the shaft that connects to the slider. In gate valves, a stuffing box area seals around the gate valve.

Therefore, knife point valves are suitable for industries such as process equipment, cement, paper, fibrous food products, etc.

.

The gate valve cleans material from the valve seat itself with each movement of the valve leaf. This is incorporated into the design and improves the overall life of the valve seat. The design helps eliminate problems, allows for greater production, and reduces labor and equipment costs.

Everything you need to know about gate valves

Everything You Need to Know About Sliders

Everything you need to know about gate valves