Valves can be used to control the flow of all types of liquids, such as air, mud, oil, water, steam, liquid metals, corrosive media, and radioactive media. Therefore, it is very important to select the most suitable valves for the piping system. To select the most suitable valve for the piping system, it is important to know the characteristics of the valve and know the selection steps and criteria.

Valve classification:

Industrial valves can be classified according to different parameters.

General categorization

The. Automatic valves: Valves that react independently depending on the type of medium (liquid, gas, etc.).

Examples: check valves, safety valves, control valves, drain valves, pressure reducing valves, etc.

B. Operated Valves: Valves that can be operated manually, electrically, hydraulically or pneumatically.

Examples: gate valves, valves, butterfly valves, butterfly valves, ball valves, plug valves, etc.

Classification of valves according to their structure:

The. Shut-off valves: The block portion moves along the center of the seat.

B. Gate valve: The block part moves along the center of the vertical seat.

w. Shut-off and ball valves: The block part is a piston or ball that rotates around its center.

d. Rocker valves: The part of the block rotates around the axis outside the seat.

It is. Butterfly valves: A disc in the block part rotates around a seat axis.

f. Sliding valves: block parts from sliding in the vertical direction of the channel.

Classification of valves according to area of application:

The. On and off valves: They are used to allow the passage or closure of media in pipes.

Examples: shut-off valves, sliding gates, ball valves, flaps, etc.

B. Recycle stop valves: used to prevent media backflow

Example: check valves

w. Regulating valves: Used to regulate the pressure and flow of the medium.

Examples: control valves and pressure reducing valves.

d. Distributor valves: Serve to change the direction of the medium flow and its distribution.

Examples: coating of T-cock valves, distribution valves and gate valves.

It is. Valves for safety purposes: Used to drain excess media to ensure the safety of the piping system and equipment when the media pressure exceeds certain values.

Examples: safety valves and protection valves.

f. Valves for other special purposes: drain valves, ventilation valves and drain valves.

Classification of valves according to driving modes:

The. Manually operated valves: Operated by handwheel, handle, lever or chain, etc.

B. Electrically actuated valves: actuated by means of a motor or other electrical device.

w. Hydraulically actuated valves: actuated by water or oil.

d. Pneumatically actuated valves: Operated by compressed air.

Classification of valves according to valve nominal pressure:

The. Vacuum valves: Absolute pressure < 0.1 MPa, that is, valves with a pressure of 760 mmHg (millimeters of mercury or millimeters of water are used to indicate the pressure).

B. Low pressure valves: Valves with normal pressure PN ≤ 1.6 MPa (Steel valves with pressure ≤ 1.6 MPa are included in the scope.)

w. Medium pressure valves: Valves with normal pressure between PN 2.5 and 6.4 MPa.

d. High pressure valves: Valves with normal pressure between PN 10.0 and 80.0 MPa.

It is. Super high pressure valves: Valves with normal pressure PN ≥ 100.0 MPa

Classification of valves according to the temperature of the working medium:

The. General valves: Valves used when the temperature of the working fluid is between 40°C and 425°C.

B. High temperature valves: Valves used when the temperature of the working fluid is between 425°C and 600°C.

w. Heat-resistant valves: Valves used when the temperature of the working fluid is above 600°C.

d. Negative valves: Valves used when the working fluid temperature is between -150°C and -40°C.

It is. Cryogenic valves: Valves used when the working fluid temperature is below -150°C.

Classification of valves according to nominal internal widths:

The. Small diameter valves: Valves with nominal internal diameter DN < 40 mm.

B. Medium diameter valves: Valves with a nominal internal diameter between DN50 and 300 mm.

w. Large diameter valves: Valves with a nominal internal diameter between DN350 and 1200 mm.

d. Oversized valves: Valves with a nominal internal diameter between DN350 and 1200 mm.

Classification of valves according to their connection to pipes:

The. Flange-connected valves: Valves connected to pipes between flanges.

B. Valves with threaded connection: Valves with internal or external threads that are connected to pipes using threads.

w. Welded valves: Valves with welded connection and welded to pipes.

d. Clamp-connected valves: Valves with clamp connection on the valve body, which are connected to pipelines with clamps.

It is. Compression connection valves: Valves connected to pipes through a compression connection.

Valve properties

Valves generally have the following two characteristics:

App Features:

Determines the main performance and application areas of valves. The following points belong to this scope:

– Purpose of valves (shut-off valves, control valves, safety valves, etc.)

– Types of valves (slide valves, valves, butterfly valves, ball valves, etc.)

– The materials of the main parts (valve body, valve cover, stems, washers, sealing surface).

– Valve transmission modes.

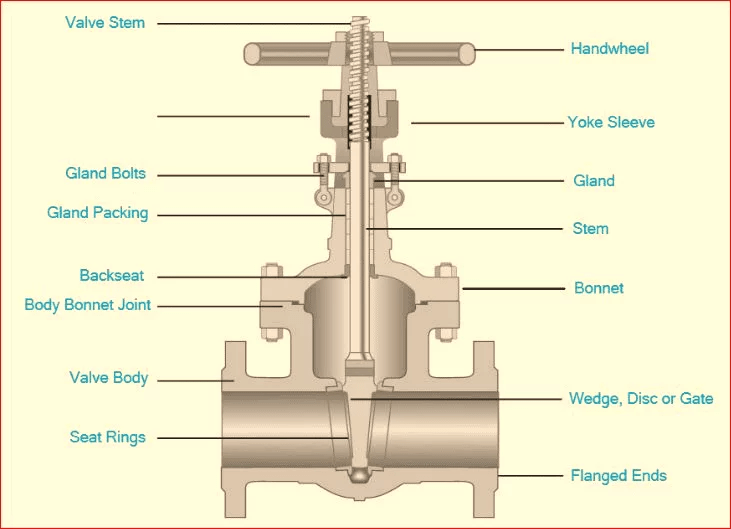

Structural features:

Determines valve installation, repair, maintenance and other methods. The following points are included in the scope:

– The total length and height of the valve.

– The ways of connecting to the pipes (flanges, clamps, internal and external threads, welding seams, etc.)

– Forms of sealing (insert rings, threaded rings, bead welding, spray welding, valve bodies).

– Valve stem construction (rotating stem, lifting stem, etc.)

Steps and criteria for valve selection

Steps to choose:

1) To confirm the applications of the valve on the equipment or devices and the working conditions of the valve, such as applicable medium, working pressure and working temperatures, etc.

2) Make sure that the nominal diameters and connection methods of pipelines to valves, such as flanges, threads or welding, etc., match.

3) Determine the types of valve actuation, that is, whether the valves can be operated manually, electrically, electromagnetically, pneumatically or hydraulically, with electrical or electro-hydraulic connection, etc.

4) According to the medium transported by the pipelines, operating pressure and operating temperature, the casings should be determined, and the internal parts should be made of gray iron, malleable iron, ductile iron, carbon steel, alloy steel, steel acid-proof stainless alloy steel or copper, etc.

5) Select the purpose of the valves, i.e. shut-off valves, control valves, safety valves, etc.

6) Make sure the type of valves, i.e. gate valves, globe valves, ball valves, butterfly valves, throttle valves, safety valves, pressure reducing valves, steam trap valves, etc.

7) For automatic valves, parameters need to be determined, i.e. allowable flow resistance, delivery capacity, back pressure, etc. The nominal pipe diameters and valve seat hole diameters must then be determined according to the different requirements.

8) Determine the geometric parameters of the selected valves, i.e. the length of the structure, the shape and size of the flange connections, the height of the valves after opening and closing, the size and number of connected screw holes and the overall size of the valves. valves

9) Existing data such as B. Use valve product catalogs, valve product samples, etc. to select suitable valve products

Selection criteria:

After understanding the steps to select a valve, we must also look at the criteria for selecting a valve.

1) Selection according to the application purposes, operating conditions and operation control methods of the selected valves.

2) Selection according to the characteristics of the working medium, that is, working pressure, working temperature, corrosive behavior, viscosity of the medium, whether it contains solid particles or whether it is toxic, flammable, explosive, etc.

3) Select the valve according to the requirements of fluid properties, i.e. flow resistance, dispensing capacity, flow characteristics and sealing degree, etc.

4) Selection according to installation size and external size requirements, i.e. nominal diameter, connection methods, pipe connection sizes, external sizes or weight limitation, etc.

5) Selection according to additional requirements of valve product electrical equipment reliability, service life and explosion-proof performance.

Some important points about selection parameters

• If valves are used for control purposes, the following parameters must also be determined:

– way of working,

– maximum and minimum flow,

– pressure drop during normal flow and closing,

– maximum and minimum pressure of the valve inlets.

• In addition to the basics and steps mentioned above, familiarize yourself in detail with the internal structures of different valve types to select valves sensibly and correctly and thus be able to select the preferred valve.

• Valves represent the final control in pipes. The flow of the medium in the pipes is controlled by opening and closing the valve.

• The shape of the valve's flow channels gives the valve certain flow properties. This must be taken into consideration when selecting the most suitable valves for the piping system.

Principles for valve selection

Valves to shut off and release the flow medium

– When the valve flow channels are straight channels and the flow resistance is low, they are generally selected as shut-off and unblock valves.

– Shut-off valves (shut-off valves, piston valves) are less preferred due to their tortuous flow paths and greater resistance to flow.

– Valves such as block valves can be used where greater resistance to flow is permitted.

Flow Control Valves

Valves selected for a specific purpose must be able to easily regulate flow.

– Downward shut-off valves (e.g. block valves) are suitable for this because the size of their seat is proportional to the stroke of the block parts.

– Rotary valves (cone valves, butterfly valves, ball valves) and flexible body valves (clamp valves, diaphragm valves) can also be used for throttle control, but are only suitable for use in a limited range of valve diameters .

– Slide valves are disc-shaped valves that move transversely to the circular valve seat. They can only regulate the flow when they are close to the closed position. Therefore, they are not typically used for flow control.

Reversing and bypass valves

Depending on reversing and bypass requirements, valves may have three or more channels. Taps and ball valves are best suited for this purpose. Therefore, most valves used for reversing and bypass are selected from one of these types. However, in some cases, other types of valves can be used for reversing and diverting as long as two or more valves are properly connected.

Valves for use in media with suspended particles

If there are particles in the middle, it is better to use valves with a cleaning function, while the block parts slide along the sealing surface. If the back and forth movement of the block parts is perpendicular to the valve seat, they may trap particles. Therefore, these valves are only suitable for particle-free media unless the sealing surface materials allow particle incorporation. Both ball valves and plug valves have a cleaning function on the sealing surface during the opening and closing process and are therefore suitable for use in particulate media.

Notes on Valve Selection

1. Gate valve selection

Gate valves are the most preferred valve types. They are suitable not only for media such as steam and petroleum products, but also for media containing granular solids and high viscosity. These valves are also suitable for ventilation and low vacuum systems. For media with solid particles, gate valve bodies should have one or two flushing holes. Special low temperature gate valves must be used for low temperature media.

2. Shutoff valve selection

The shut-off valve is suitable for pipelines that do not have strict requirements for fluid resistance, that is, pressure loss. They can be considered for high temperature and high pressure piping or equipment, as well as for piping with steam media and DN < 200mm. Globe valves can be used for small valves, such as: For example, pin valves, instrument valves, sampling valves, pressure measuring valves, etc. In flow or pressure control, shut-off valves or choke valves are preferred because of their low precision and relatively small diameters. For highly toxic media, bellows shut-off valves must be used. However, they should not be used for media with high viscosity and easily settleable particles. These valves cannot be used as vent valves and valves for low vacuum systems.

3. Ball valve selection

The ball valve is suitable for low temperature, high pressure and high viscosity media. Most ball valves can be used in media with suspended solid particles and can also be used in powder and granular media depending on the requirements of sealing materials. Full channel ball valves are not suitable for flow regulation, but are suitable for situations where rapid opening and closing is required for shutdown in emergencies or accidents. Ball valves are recommended in pipelines with strict sealing performance, wear, contraction channels, fast opening and closing operations, high pressure stopping (large differential pressure), low noise, gassing, low operating torque and low fluid resistance. They are also suitable for light structures, low pressure stops and corrosive media.

Low temperature ball valves with covers are the most ideal valves for cryogenic and low temperature media and are used in low temperature media piping systems and equipment. When selecting ball valves with floats, the seat materials must withstand the ball and working fluid loads. Large diameter ball valves require greater torque during operation. For ball valves with DN≥200mm, a helical gear is preferred for operation. Furthermore, ball valves used in pipelines for highly toxic materials and flammable media must be fireproof and antistatic.

4. Choosing the throttle body

Butterfly valves are suitable for places where the temperature of the medium is low and the pressure is high. They are also suitable for locations where flow and pressure need to be regulated. However, they are not suitable for media with high viscosity and solid particles. Therefore, they cannot be used as shut-off valves.

5. Plug valve selection

In general, chick taps are suitable for situations where quick opening and closing is required. They are also suitable for low-temperature, high-viscosity media and media with suspended particles, but not for steam and high-temperature media.

6. Shutoff valve selection

Butterfly valves are suitable for pipelines with large diameters (e.g. DN > 600 mm) and short lengths, as well as for fast flow control and fast opening and closing requirements. They are generally used for water, oil and compressed air and other media with temperature ≤ 80°C and pressure ≤ 1.0 MPa. Compared to gate valves and ball valves, butterfly valves are suitable for piping systems with less severe pressure loss due to their relatively large pressure loss.

7. Check valve selection

Check valves are generally suitable for clean media, but not for media with solid content and high viscosity.

– If DN≤40mm, check valves must be used (installation only permitted on horizontal pipes).

– For DN = 50-400 mm, check valves with an oscillating lever must be used (installed in horizontal and vertical pipelines. When installed in vertical pipelines, the direction of flow of the medium must be from bottom to top).

– For DN≥450mm, plug type check valves must be used.

– For DN = 100–400 mm, wafer check valves can also be used.

The check valve can be made for very high operating pressures and the PN can reach up to 42MPa. Depending on the housing and seal material, they can be used for various operating media such as water, steam, gas, corrosive media, oil, etc. and operating temperatures in the range between -196 and 800 °C.

8. Diaphragm valve selection

Diaphragm valves are suitable for oil, water, acidic media and media with suspended particles at operating temperatures below 200 °C and pressures below 1.0 MPa. However, they are not suitable for organic solvents and strongly oxidizing media.

– For abrasive granular media, weir type diaphragm valves should be selected. When selecting weir-type diaphragm valves, pay attention to the flow characteristics tables.

– Straight diaphragm valves must be used for media consisting of viscous liquids, cement pastes and sediments.

– Diaphragm valves must not be used in vacuum lines and vacuum equipment unless special requirements apply.

Different types of valves have a wide range of applications and are frequently operated. Valves are used in many areas of everyday life. The function of valves is very important to ensure the normal operation of the piping system and prevent the occurrence of the “drip and leak” phenomenon. Therefore, it is very important to understand the valve structure, its operation and its working conditions to choose the correct valve.