STEEL IN THE BRAZILIAN INDUSTRY

How to choose the right face mill: a guide

The main tool for machining flat parts is a face mill, which has cutting edges along its circumference and end face. The cutting edge of the end face is considered...

How to choose the right face mill: a guide

The main tool for machining flat parts is a face mill, which has cutting edges along its circumference and end face. The cutting edge of the end face is considered...

The Ultimate Guide to Twist Drill Selection

Overview For drilling, there are three basic criteria to consider when selecting a drill: material, coating and geometric characteristics. 1. Material The materials used for drilling...

The Ultimate Guide to Twist Drill Selection

Overview For drilling, there are three basic criteria to consider when selecting a drill: material, coating and geometric characteristics. 1. Material The materials used for drilling...

Essential CNC Calculation Formulas You Should K...

I. Trigonometric calculation 1.tgθ=b/a ctgθ=a/b 2.Sinθ=b/c Cos=a/c II. Calculation of cutting speed Vc=(πDS)/1000 Vc: linear speed (m/min) π: Circumference (3.14159) D: Tool diameter...

Essential CNC Calculation Formulas You Should K...

I. Trigonometric calculation 1.tgθ=b/a ctgθ=a/b 2.Sinθ=b/c Cos=a/c II. Calculation of cutting speed Vc=(πDS)/1000 Vc: linear speed (m/min) π: Circumference (3.14159) D: Tool diameter...

Metal Machining: Top 5 Cutting Tool Materials

See also: Basic Guide to Cutting Tool Materials (How to Choose?) Types of Cutting Tool Materials 1. High-speed steel High-speed steel is a type of tool steel known for...

Metal Machining: Top 5 Cutting Tool Materials

See also: Basic Guide to Cutting Tool Materials (How to Choose?) Types of Cutting Tool Materials 1. High-speed steel High-speed steel is a type of tool steel known for...

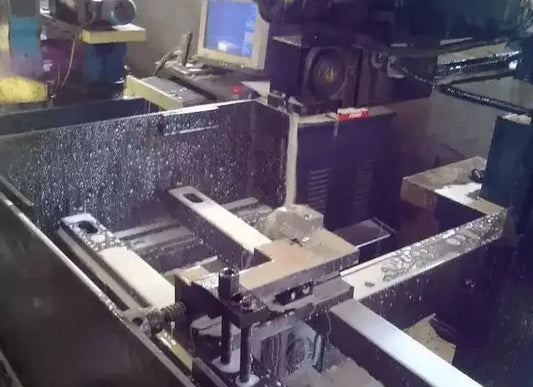

Top 6 Trends Shaping the CNC Machine Tool Indus...

1. Multifunctional Speed and accuracy are two critical factors in CNC machines, impacting machining efficiency and product quality. The CNC system employs a high frequency processor...

Top 6 Trends Shaping the CNC Machine Tool Indus...

1. Multifunctional Speed and accuracy are two critical factors in CNC machines, impacting machining efficiency and product quality. The CNC system employs a high frequency processor...

12 Expert Tips for Reducing Vibrations on CNC M...

01 Sharp inserts can be used to reduce the cutting force of CNC milling machines. Pinned inserts come in coated and uncoated varieties. Uncoated tablets are typically...

12 Expert Tips for Reducing Vibrations on CNC M...

01 Sharp inserts can be used to reduce the cutting force of CNC milling machines. Pinned inserts come in coated and uncoated varieties. Uncoated tablets are typically...