STEEL IN THE BRAZILIAN INDUSTRY

Understand and avoid or reduce vibrations durin...

Machining vibration occurs in almost all manufacturing processes. The heavy machines used in manufacturing generate strong vibrations, resulting in poor surface finish and deterioration...

Understand and avoid or reduce vibrations durin...

Machining vibration occurs in almost all manufacturing processes. The heavy machines used in manufacturing generate strong vibrations, resulting in poor surface finish and deterioration...

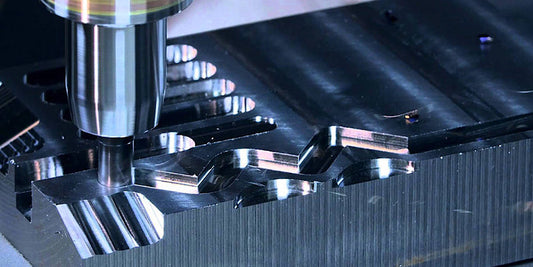

4 common part errors and their causes in CNC mi...

CNC milling is one of the most commonly used part machining methods when you need to produce a high-precision part. Modern CNC milling tools offer great opportunities...

4 common part errors and their causes in CNC mi...

CNC milling is one of the most commonly used part machining methods when you need to produce a high-precision part. Modern CNC milling tools offer great opportunities...

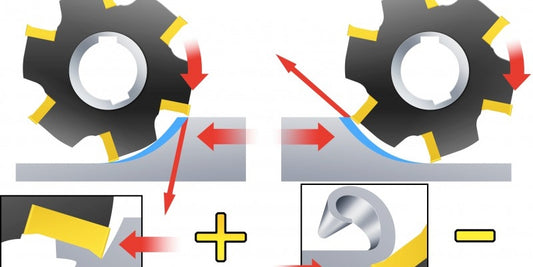

CNC Milling Tips: Learn When to Use Down Millin...

Experts use numerous CNC milling techniques to get the most out of their CNC machine, depending on the size, shape, features and material of the part being machined....

CNC Milling Tips: Learn When to Use Down Millin...

Experts use numerous CNC milling techniques to get the most out of their CNC machine, depending on the size, shape, features and material of the part being machined....

A Guide to CNC Milling of Curved Surfaces

Milling curved surfaces falls under the term CNC profile/contour milling. Irregularly shaped profiles or continuous curves with different degrees (oblique, concave...) are processed.

A Guide to CNC Milling of Curved Surfaces

Milling curved surfaces falls under the term CNC profile/contour milling. Irregularly shaped profiles or continuous curves with different degrees (oblique, concave...) are processed.

Thinning vs. machining finish: What are the dif...

In general, the basic principles of CNC machining include standard subtractive manufacturing operations such as turning, milling, facing, drilling, grooving, boring, etc. These processes involve...

Thinning vs. machining finish: What are the dif...

In general, the basic principles of CNC machining include standard subtractive manufacturing operations such as turning, milling, facing, drilling, grooving, boring, etc. These processes involve...

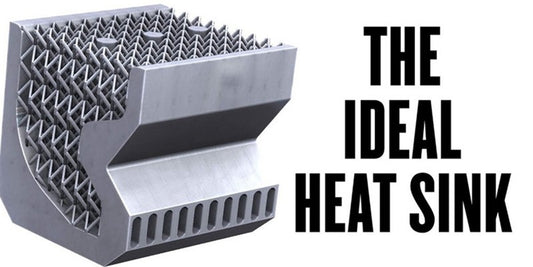

Heatsink Design Basics: Factors and Calculation

Heat sinks are the most easily forgotten components in electrical machines and circuits. However, this is not the case when designing hardware as heatsinks perform...

Heatsink Design Basics: Factors and Calculation

Heat sinks are the most easily forgotten components in electrical machines and circuits. However, this is not the case when designing hardware as heatsinks perform...