Heat sinks are the most easily forgotten components in electrical machines and circuits. However, this is not the case when designing hardware as heatsinks play a very important role. Almost all technologies, including CPUs, diodes, and transistors, generate thermal energy, which can reduce thermal performance and make operation inefficient.

To address heat dissipation challenges, different types of heat sinks are developed to power different elements and ensure they operate at the ideal temperature for each.

With the rapid development of technology (especially nanotechnology) and the development of the most compact and efficient products possible, correct heat sink design has become a check and balance factor in the production of electrical products. Therefore, this article will discuss the details and design considerations of heatsinks.

What is a heatsink?

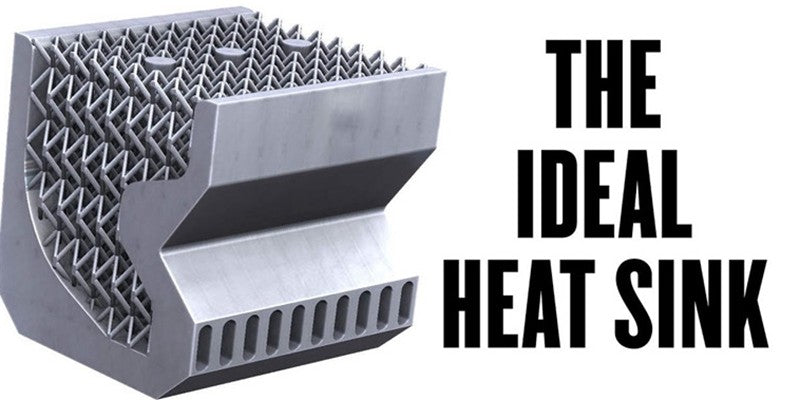

A heat sink is a device that dissipates excess heat from another component. In an integrated circuit, a heat sink is made of a material with high thermal conductivity to dissipate unwanted heat. This works by increasing the surface area and allowing cooler air or liquid to flow over the surface.

According to Fourier's law, heat is transferred from a hotter area to a colder area. A heat sink based on this law operates across a temperature gradient. It absorbs unwanted heat generated in an electrical component and transfers it to cooler air or liquid through heat transfer methods such as conduction or natural convection.

Types of heat sinks

The first step in identifying the heat sink design is to determine the type of configuration. There are two common types of heat sinks.

Passive heat sinks

Passive heat sinks are the conventional option as they utilize natural airflow. Natural convection forms above the heat sink, which moves heat away from the component. They are cheaper to operate and do not require additional electricity to operate.

Active heat sinks

Active heat sinks are more efficient and powerful, but require forced convection with air or liquid to allow heat transfer. They are easy to spot because they use electrical devices such as a fan near the heatsink.

The choice of a heatsink leads to design differences. For example, active heatsinks with fans require a smaller surface area and lighter material to dissipate the same amount of heat as a passive conductor.

Factors and considerations in heat sink design

Each heatsink works on the same basic principle. First, heat is generated in a component and the heat sink helps dissipate that heat. A heat sink connected to the component or circuit receives heat through heat conduction or heat pipes. The thermal conductivity of the heat sink material significantly influences this process.

Then heat transfer occurs within the entire heat sink. The passive heat exchanger or heat sink is hotter near the heat source and cooler at the other end because this natural conduction distributes heat unevenly across the surface.

The heat is then dissipated by natural and forced convection. Air or liquid flowing directly over the surface of the heat sink removes heat generated by diffusion and releases it into the surrounding air.

It is now clear that many factors influence heatsink performance, including material, geometry and coolant type. These parameters must be considered before manufacturing a heat sink.

1. Thermal resistance

Thermal resistance can simply be defined as the combined thermal resistance experienced by heat generated as it moves through a temperature gradient. These include thermal resistance within the heat sink assembly, any friction, and thermal energy losses due to resistance between the coolant and the heat exchanger surface.

Thermal resistance can be calculated using the thermal resistance value. It is extremely useful for finding the most effective thermal resistance for components and ICs.

2. Types of materials

The design of the heatsink is largely influenced by the material chosen. Popular materials for heat sinks include aluminum alloys such as AA 6063-T6 and copper, tungsten or copper molybdenum. Copper heat sinks offer excellent thermal conductivity and corrosion resistance, but are heavier and more expensive than aluminum. In addition, laboratory-grown diamonds (Chemical Vapor Diamonds, CVDs) are used, whose thermal conductivity comes from vibrations within their reticular structure.

Other heat-producing devices affected by thermal resistance include lithium-ion batteries used in cars. Heat dissipation from these batteries is critical, otherwise thermal runaway can lead to a chain reaction that destroys the battery. A carbon fiber heat sink with higher conductivity offers the automotive industry a thermal management solution.

3. Heatsink Fins

Fins are the component of a heat sink that allows the transfer of heat from the heat sink to the ambient temperature. The shape and location can have a big impact on how the heat sink transfers power, while the size and number of these fins determine their efficiency.

3.1 Arrangement, shape, size and position of slats

The fins are the places where the cooling medium flows over the heat sink like air, allowing heat to dissipate. Therefore, arrangement and size are important when designing heat sinks. Improving these factors can lead to better heat dissipation and easier heat flow. In a study published in Science Direct, the results of a report discussed how shape can affect the thermal management of heatsinks.

“The results showed that circular fins improved the thermal performance of the heat sink and reduced thermal resistance by 25% and 12%, respectively, than the other two shapes” – Case Studies in Thermal Engineering

3.2 Coverslip efficiency

Electrical components in large technology units, such as servers, produce excessive heat. Slow heat transfer can reduce performance and lifespan. A heat pipe and liquid cooling offer great potential, but a finned heat exchanger is essential for reliable, continuous heat dissipation.

Fins increase the surface area for energy dissipation in electrical components, and factors such as thickness, height, and thermal resistance affect fin efficiency. To improve efficiency, the thermal boundary layer is thinner and the air direction is set at the ideal angle, and the heat sink itself is made of a material with high thermal conductivity.

4. Thermal conductive material

The heat sink must be connected to electrical components and circuits. The interface between the heat exchanger and typical electrical components is called heat conductive material.

Thermal interface resistance can reduce heat sink efficiency and surface roughness, and trapped air and voids can increase thermal contact resistance. It is clear that heat transfer is poor with these interface defects, and to decrease thermal resistance, various thermal interface materials such as phase change materials are used. The thermal resistance of the component is reduced as air is removed and cavities are filled, ensuring complete contact.

5. Heat sink fixing methods

A heat sink is used in many places, including mechanical components. The choice of heat sink assembly can significantly improve maximum power dissipation and dissipate more thermal energy. Commonly used methods include heat tape, epoxy, clips, and pins.

Many factors in heat sink design influence the choice of mounting. For example, large and heavy heatsinks cannot be supported with thermal strips. Epoxy resin is a good choice for thermal management solutions, but it is expensive and requires skill to apply.

Heat Sink Design: Calculation of Thermal Resistance

The heatsink design completes the geometry and functionality for its intended use. However, to evaluate the heat dissipation performance of heat sinks, some thermal resistance calculations are necessary.

Some terms you should know:

T Crossing : Maximum operating temperature of the junction

T Ambient : Ambient temperature

P : Heat generated

T Connection box : Connection to the box resistance

T interface : resistance of the interface material

T Heatsink : Thermal resistance of the heatsink

Total thermal resistance is the resistance to heat flow from the junction to the case, the thermal resistance of the interface material, and the resistance between the heat sink and ambient air.

The above calculations are also used in the design phase to make comparisons between different materials and interfaces and to determine the correct thermal resistance that corresponds to the component's maximum operating temperature.

Heatsink design: size calculation

The first step in sizing a heat sink is to determine its dimensions. Once the dimensions are determined, the next step is to do some calculations, which are made easy by the heatsink calculator.

- Determine the heat of convection

P C = 2hA(T compensation -T Ambience )

Where

A = HL + t(2H + L)

h = 1.42(( T compensation -T Environment )/H ) >0.25

PC C : 2hA(T compensation -T Ambient )

- You will notice that there is another surface for heat dissipation. The convection heat in A 2

P C = 2 hours 2 A 2 (T compensation -T Environment )

Where

A 2 = L(2(H – b) + sb) + tL

s = 2.71 (gβ (T compensation -T Environment )/Lαv )

- Determination of heat emitted by radiation.

Like convection, heat can escape from both surfaces through radiation.

P R = 2ϵσA 1 (T 4 compensation -T 4 Environment )

P r2 = 2ϵσA 2 (T 4 compensation -T 4 Environment )

Where

A 2 = I(t + s) + 2(tH + sb)

- Finally, the number of fins is given by

F N = 1 + (( P – P r2 – P c2 ) / ( P r1 + P c1 ))

- The width of each slat is given by

W = (N – 1) + Nt

Heat sink applications

Heat sinks are used where heat is generated and this needs to be constantly regulated to maintain the operating temperature within the maximum allowable temperature. In electrical devices, heat sinks can be found almost everywhere you see LEDs and transistors. This means they remain functional at room temperature without overheating.

The application of heat sinks is largely characterized by the rate at which they conduct heat. Therefore, materials with higher thermal conductivity are used for processes where an increase in temperature represents a risk to operations.

CPUs

When computers are used and CPU chips are overclocked, significant heat is generated. A heatsink thermally coupled to a CPU can not only store this heat and quickly dissipate it from the chip, but also transfer it across its surface and ultimately release it into the surrounding air.

Power amplifier

In power transistors, the heat generated can cause current leakage. This increase in collector current can in turn increase power dissipation, which in turn can increase temperature. This can lead to thermal runaway, which destroys the transistor. A heat sink can quickly dissipate the heat generated on its surface, preventing damage.

Optoelectronics

Heat sinks are often used with LEDs because the component itself is unable to regulate its operating temperature.

Common Manufacturing Methods for Heatsink Designs

To develop an effective heat sink design, engineers must consider many different factors, such as material selection. Aluminum is the most commonly used material to make heat sinks. In this section, we will discuss the three most common methods of manufacturing aluminum heat sinks.

Heatsink Extrusion

The extrusion process is suitable for simpler heat sink designs characterized by high production volumes, lower investments, short development cycles and low production costs.

The commonly used aluminum extrusion material is 6063 aluminum, which has good thermal conductivity. The working principle is to heat the aluminum ingot to 520-540°C under high pressure to make the aluminum liquid flow through the slotted extrusion mold and form the heat sink embryo. Then, the heat sink embryo, profile groove and other processing steps are cut from the heat sink fins that we often see.

CNC machining of heat sinks

CNC machining includes a variety of processes such as turning, drilling, milling and grinding. This process can be flexibly applied according to the structure of parts and the use of most structural parts, such as: Such as plate forming, heat sink grooves, bottom surface processing, etc. This method is particularly suitable for the design of heat sinks with complex geometry.

Cast Heatsink

The principle of cast aluminum heat sinks is similar to injection molding. The raw material aluminum alloy is dissolved in liquid under high pressure, and then the liquid material is quickly filled into the mold. According to the model, the casting machine started working and a monomer heat sink was made through single molding after cooling and subsequent treatment. The process can be integrated into a thin, dense or complex heat sink fin design.

University Degree

The uses of heat sinks will continue to expand as more technical advances are made and better solutions are found to make a process more useful. Heatsink design is also becoming more diverse and individual.