STEEL IN THE BRAZILIAN INDUSTRY

Soldagem em Alumínio: Principais cuidados e Téc...

O alumínio é um material amplamente utilizado na indústria e na construção civil devido às suas propriedades únicas, como leveza, resistência à corrosão e alta condutividade elétrica e térmica. No...

Soldagem em Alumínio: Principais cuidados e Téc...

O alumínio é um material amplamente utilizado na indústria e na construção civil devido às suas propriedades únicas, como leveza, resistência à corrosão e alta condutividade elétrica e térmica. No...

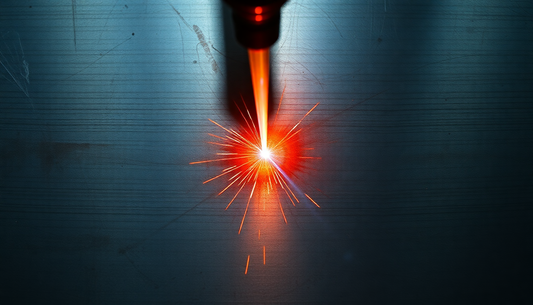

Como lidar com Rachaduras na Solda ao Resfriar ...

A soldagem é uma técnica fundamental na indústria e construção, permitindo a união de peças metálicas de forma eficiente e resistente. No entanto, um desafio comum que os profissionais enfrentam...

Como lidar com Rachaduras na Solda ao Resfriar ...

A soldagem é uma técnica fundamental na indústria e construção, permitindo a união de peças metálicas de forma eficiente e resistente. No entanto, um desafio comum que os profissionais enfrentam...

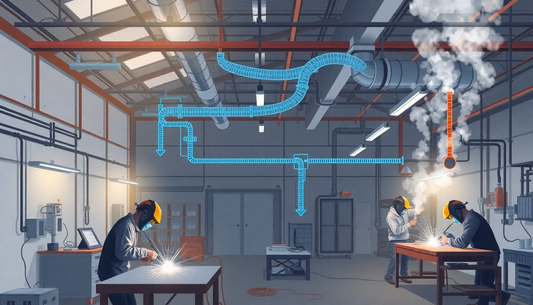

A Importância da Ventilação adequada no Ambient...

A soldagem é uma técnica amplamente utilizada em diversos setores industriais, desde a fabricação de estruturas metálicas até a construção civil. No entanto, essa atividade apresenta riscos significativos à saúde...

A Importância da Ventilação adequada no Ambient...

A soldagem é uma técnica amplamente utilizada em diversos setores industriais, desde a fabricação de estruturas metálicas até a construção civil. No entanto, essa atividade apresenta riscos significativos à saúde...

Soldagem com Eletrodo Revestido: Vantagens, Des...

A soldagem com eletrodo revestido, também conhecida como SMAW (Shielded Metal Arc Welding), é um processo amplamente utilizado na indústria e na construção civil. Essa técnica de soldagem se destaca...

Soldagem com Eletrodo Revestido: Vantagens, Des...

A soldagem com eletrodo revestido, também conhecida como SMAW (Shielded Metal Arc Welding), é um processo amplamente utilizado na indústria e na construção civil. Essa técnica de soldagem se destaca...

Como escolher o eletrodo certo para cada tipo d...

A escolha do eletrodo certo para cada tipo de metal é fundamental para garantir a qualidade e a segurança da soldagem. Cada metal possui características específicas, como resistência mecânica, composição...

Como escolher o eletrodo certo para cada tipo d...

A escolha do eletrodo certo para cada tipo de metal é fundamental para garantir a qualidade e a segurança da soldagem. Cada metal possui características específicas, como resistência mecânica, composição...

Diferenças entre MIG/MAG: Entenda os dois Proce...

A escolha do processo de soldagem adequado é fundamental para garantir a qualidade e a eficiência de qualquer projeto de fabricação ou construção. Neste artigo, vamos explorar as diferenças entre...

Diferenças entre MIG/MAG: Entenda os dois Proce...

A escolha do processo de soldagem adequado é fundamental para garantir a qualidade e a eficiência de qualquer projeto de fabricação ou construção. Neste artigo, vamos explorar as diferenças entre...