During the manufacturing of stainless steel parts, deformation of parts is a common problem that occurs as a result of welding. This deformation is only a superficial phenomenon, caused by the overheating of the weld metal and the heat-affected area due to the welding heat source. This overheating often results in coarse-grained structures in the weld metal and heat-affected zone, which can lead to defects and negatively impact the performance of the metal.

To prevent these negative effects and control the temperature of the parts, it is important to regulate the temperature of the parts. However, waiting for parts to cool before proceeding with the next welding process can be time-consuming and negatively impact work efficiency.

To solve this problem, several solutions have been proposed. In specific welding processes, the volume of the parts is closely related to the density of the weld bead and welding feet. For example, in the processing of stainless steel sheet parts, the heat source (arc) melts the base metal (parts) during welding, forming a molten pool. After natural cooling and crystallization, the weld seam is formed.

However, when parts are very small, the welding heat cannot be distributed quickly, leading to distortion of the parts and affecting their appearance and shape. To solve this problem it is necessary to address several aspects.

Welding scheme

Currently, there are two common welding methods used for welding stainless steel in most factories:

⑴ Arc welding with welding electrode

The first method of welding is a more traditional method that requires a high level of skill from the welder. This method has a significant impact on the heat of the parts, resulting in long processing times after welding and poor quality control.

However, the equipment used for this method is relatively simple and can be used to weld various materials with flexible welding rods.

⑵ Gas shielded welding

Gas shielded arc welding can be divided into several methods, including argon arc welding for stainless steel welding, which uses argon or a gas mixture (MAG welding) as the shielding gas. The advantage of gas shielded welding is its fast welding speed, small thermal influence area and simple post-welding processing.

To minimize the thermal influence on the parts when welding stainless steel, it is recommended to use gas shielded welding as much as possible. In the welding design process, it is important to adopt alternating welding methods such as right-left, symmetrical and back-step alternating welding, following the principles of first in and then out, first less and then more, and first short and then long .

Welding parameters such as welding current and arc voltage can also impact welding deformation. As the size of stainless steel components increases, the welding current must also increase. However, it is important to strictly control the welding current to ensure uniform welding heating. If the welding current is too low, it may affect the welding quality, while if it is too high, it may cause more serious welding deformations.

Therefore, welding parameters such as welding current and arc voltage must be adjusted based on the material thickness and welding requirements.

Welding Technology

⑴ Small and simple parts

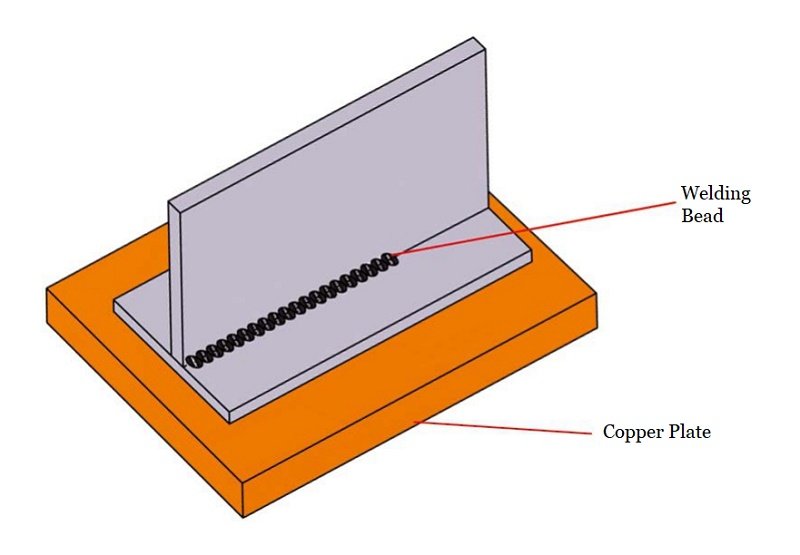

For example, in case the welding method is L-shaped, T-shaped or overlapping pieces on a flat plane, a copper plate (thickness greater than 8mm) can be added under the pieces, as illustrated in Figure 1 .

Fig.1 bottom of copper plate

The heat transfer efficiency of copper is higher than that of steel, so the use of a copper plate can facilitate the removal of welding heat and minimize the thermal deformation of parts.

If the parts are not flat or tend to swell, making close contact with the copper plate difficult, you can place a thick cotton material with high water absorption or a soaked mat under the solder bead of the parts. This will also effectively reduce deformation.

⑵ Large and complex parts

If the shape of the parts is complex or there is no space for a copper plate, the above solution may not be viable. In these cases, the water cooling method must be employed (as shown in Figure 2).

Fig.2 water cooling method

Water cooling is generally classified into two categories:

① Spray cooling:

In this method, water is sprayed on the back of the weld bead of the parts, which is suitable for parts with larger areas. It is crucial to adjust the angle of the water stream for T- or L-shaped overlap to prevent water from flowing into the welding position.

The advantage of this method is that it provides efficient cooling and is convenient for mass production. However, the disadvantage is that it requires special equipment and is only suitable for single-type processed parts.

② Wet sand cooling:

The spray cooling method is not applicable for flat joint welding because it cannot guarantee that water will not flow into the welding path. The wet sand cooling method can be used. This involves filling containers (larger than the parts for welding) with sand, fully saturating the sand with water, and laying the parts flat in the damp sand before welding.

This allows the rear part of the parts weld bead to be in full contact with the wet sand and welding can then begin. The advantage of this method is its simple operation and suitability for all complex shapes. The disadvantage is that it is not easy to manufacture large parts.

⑶ Welding of large plate parts

Generally refers to the welding of parts thicker than 6 mm. Due to the large size of the parts, the long weld length and the high welding height (large molten pool area and extensive hot zone), bending deformation caused by thermal deformation may occur during welding. To resolve this problem, several measures must be taken:

① Suitable cooling measures must be prepared before welding (refer to the cooling scheme for small parts);

② Welding tolerance for deformation:

Since it is difficult to achieve symmetrical or simultaneous welding on one side for most parts, uneven heating will result in bending deformation during welding. To mitigate this, deformation of parts must be counteracted in the opposite direction of deformation, based on part length, material thickness (weld bead height), and shape.

This requires experienced technical and engineering personnel and skilled workers to make judgments based on experience. Fixtures are used to fix the parts, and after the first part is manufactured, fine adjustments are made according to the actual effect.

Fig.3 weld tolerance for deformation

Stress relief after welding parts

Compared with the common welding of carbon steel parts, the thermal conductivity coefficient of stainless steel is lower, and its electrical resistance and expansion coefficient are higher. As a result, heat transfer in stainless steel is slower and thermal deformation is greater.

Even if the surface deformation of parts is not noticeable after manufacturing, changes may occur during transportation or due to vibration, movement or temperature changes, which directly affect the appearance, size and performance of the parts.

Therefore, it is important to relieve stress on large parts after manufacturing, especially for thick parts (with high welding height and large weld pool) and parts with multiple weld beads. Stress relief can be achieved through natural or artificial aging.

Natural aging is typically used for large castings, but it is not suitable for general welded parts, and the aging process is long and difficult to control.

Artificial aging is divided into heat treatment aging and vibration aging.

Heat treatment aging involves heating parts to a temperature of 550 to 650℃ to perform stress annealing. This method is more time-efficient than natural aging, but factories often do not have the necessary processing conditions and outsourcing the process increases transportation costs. As a result, heat treatment aging is not commonly used.

Vibration aging is a widely used method to eliminate residual internal stresses in engineering materials. Reduces the plastic deformation of components caused by internal residual stress through vibration, effectively relieving stress.

The principle of vibratory aging involves placing a motor system with an eccentric block (vibrator) in the artifact and loading the components with elastic objects such as rubber pads. The motor is driven by the controller and the speed is adjusted to achieve resonance in the artifact.

A vibration treatment of 20 to 30 minutes can effectively adjust internal stress, and the accumulated vibration time should not exceed 40 minutes.

This method requires few processing site requirements and is simple to operate, making it a commonly adopted method by most factories. The structure and appearance of the parts are not affected by the external environment, ensuring the stability of the parts.

Conclusion

In conclusion, welding deformation is an inevitable occurrence in stainless steel welding and can have a significant impact on the machining and practical use of stainless steel components. To minimize these effects, more time and attention should be devoted to welding technology, including welding method, technical parameters, sequence, component positioning and retention, and post-welding processing, to control welding distortion to the smallest extent possible.

When controlling each manufacturing process, technical and engineering personnel and welding operators must work closely, combining theoretical data with the actual situation, and develop a reasonable construction plan to fully control welding deformation. Only in this way will it be possible to produce a more perfect product.