STEEL IN THE BRAZILIAN INDUSTRY

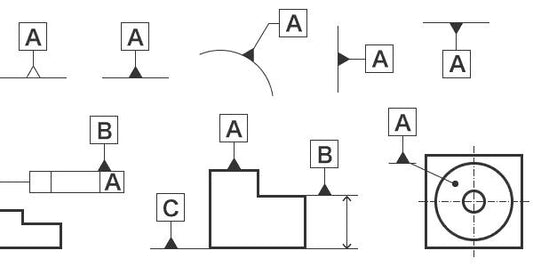

What are reference points in GD&T and their...

Geometric Dimension Tolerance (GD&T) is the foundation of modern precision manufacturing. It is an efficient system for designers to communicate functional mechanical tolerance and requirements in a way that...

What are reference points in GD&T and their...

Geometric Dimension Tolerance (GD&T) is the foundation of modern precision manufacturing. It is an efficient system for designers to communicate functional mechanical tolerance and requirements in a way that...

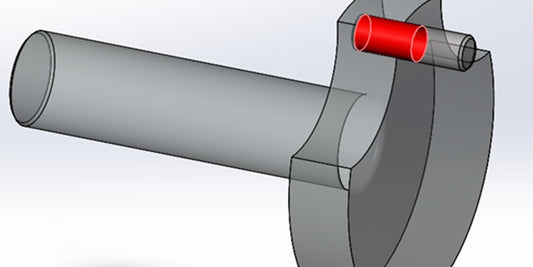

Differences Between Press Fit and Slide Fit in ...

Technical adjustments are an important aspect in producing well-functioning mechanical assemblies. Therefore, designers must understand the nuances between different types of pr...

Differences Between Press Fit and Slide Fit in ...

Technical adjustments are an important aspect in producing well-functioning mechanical assemblies. Therefore, designers must understand the nuances between different types of pr...

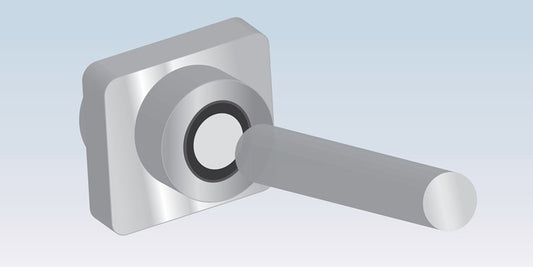

Tuning Types: How to Select a Tuning for an Eng...

The true art of engineering is evident in complex mechanical assemblies. Take a look inside a wristwatch. The perfect harmony in which all the little components work together is...

Tuning Types: How to Select a Tuning for an Eng...

The true art of engineering is evident in complex mechanical assemblies. Take a look inside a wristwatch. The perfect harmony in which all the little components work together is...

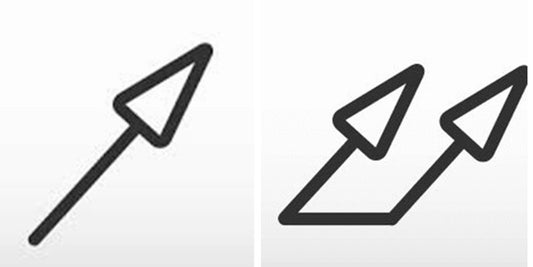

O que é Concentricidade: Explicação do Símbolo ...

Runout é um defeito de fabricação que ocorre especificamente em componentes rotodinâmicos. Como quase todas as indústrias dependem de máquinas como bombas, caixas de velocidades, eixos, etc., este ...

O que é Concentricidade: Explicação do Símbolo ...

Runout é um defeito de fabricação que ocorre especificamente em componentes rotodinâmicos. Como quase todas as indústrias dependem de máquinas como bombas, caixas de velocidades, eixos, etc., este ...

Resistance vs. Rigidity vs. Hardness: What are ...

Increasing materials research is a major factor in the rise of modern manufacturing. The variety of materials that can be machined is also increasing in CNC machining, and it is...

Resistance vs. Rigidity vs. Hardness: What are ...

Increasing materials research is a major factor in the rise of modern manufacturing. The variety of materials that can be machined is also increasing in CNC machining, and it is...

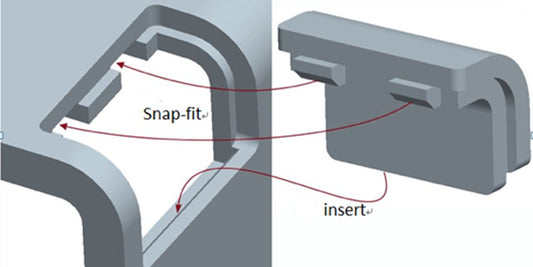

Instant Attachments: Types, Benefits, and Best ...

One-touch connections are one of the most common mechanical connection mechanisms found in products around us. The action of “taking something” usually refers to a background snap. Tupp caps...

Instant Attachments: Types, Benefits, and Best ...

One-touch connections are one of the most common mechanical connection mechanisms found in products around us. The action of “taking something” usually refers to a background snap. Tupp caps...