STEEL IN THE BRAZILIAN INDUSTRY

Fatigue fracture: types, characteristics and so...

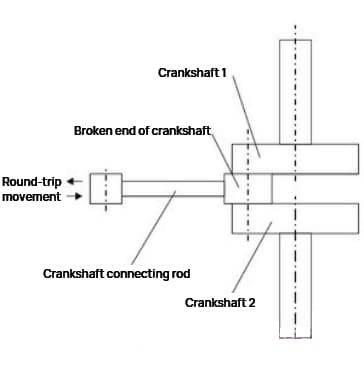

1. Concept of fatigue and fracture Fatigue: Fatigue refers to the change in performance of metallic materials when subjected to repeated stress or deformation. Fatigue fracture: When a material...

Fatigue fracture: types, characteristics and so...

1. Concept of fatigue and fracture Fatigue: Fatigue refers to the change in performance of metallic materials when subjected to repeated stress or deformation. Fatigue fracture: When a material...

Steel Section Flexural Strength Calculation: A ...

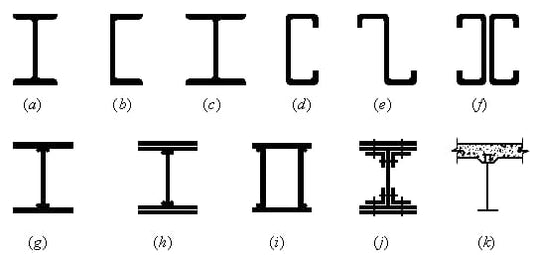

Chapter One: Introduction 1. Concept: Supports lateral loads such as floor beams, crane beams, purlins, bridges, etc. 2. Classification: (1) Solid web: H-shaped steel section: Easy to pro...

Steel Section Flexural Strength Calculation: A ...

Chapter One: Introduction 1. Concept: Supports lateral loads such as floor beams, crane beams, purlins, bridges, etc. 2. Classification: (1) Solid web: H-shaped steel section: Easy to pro...

Cross-sectional area table for metric threads

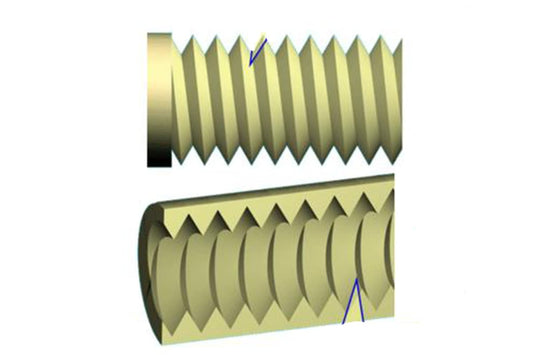

Here is the cross-sectional area table for metric threads, the units are in millimeters and square millimeters. (The so-called cross-sectional area refers to the effective supporting area...

Cross-sectional area table for metric threads

Here is the cross-sectional area table for metric threads, the units are in millimeters and square millimeters. (The so-called cross-sectional area refers to the effective supporting area...

10 Aluminum Die Casting Defects Explained

Die casting is a metal casting process that uses a mold cavity to force molten metal into a specific shape, similar to the plastic injection molding process.

10 Aluminum Die Casting Defects Explained

Die casting is a metal casting process that uses a mold cavity to force molten metal into a specific shape, similar to the plastic injection molding process.

Types of anodizing defects in aluminum alloys

Premake Various defects produced in the production of oxidation of aluminum and aluminum alloys can be divided into three categories: Surface defects of oxidation surface treatment products...

Types of anodizing defects in aluminum alloys

Premake Various defects produced in the production of oxidation of aluminum and aluminum alloys can be divided into three categories: Surface defects of oxidation surface treatment products...

Exploring 12 types of heat exchangers: principl...

1. Tubular heat exchanger Principle Each segment of the shell is called “single pass”. The inner tube (heat transfer tube) of the pass is connected by elbow-shaped tubes...

Exploring 12 types of heat exchangers: principl...

1. Tubular heat exchanger Principle Each segment of the shell is called “single pass”. The inner tube (heat transfer tube) of the pass is connected by elbow-shaped tubes...