Floating columns are used as a structural element that supports loads or are used to confine materials like a brick in construction to prevent thermal cracks.

There are mainly two types of floating columns in buildings and other structures.

- Structural floating columns

- Rigid columns

Both types of supports are of great importance in construction and their purpose is very different.

Let's discuss them one by one.

Structural floating columns

A structural column is an element that supports the load transmitted by slabs, beams, brackets or other elements connected to it.

The loads are mainly in the form of tensile or compressive loads. Therefore, structural floating supports can be divided into two main categories.

- Compression Columns

- Tension Columns

Compression Columns

This category includes columns that absorb axial compression forces. Floating columns are often used as support columns in construction.

The various occasions on which we built the floating column can be highlighted below.

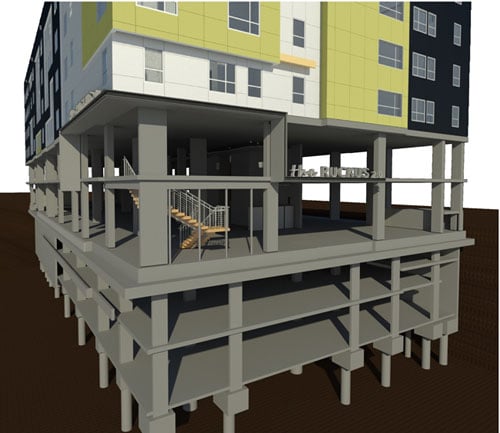

- On transfer floors

Generally, greater column spacing is needed to meet requirements such as: B. to meet car loading, vehicle traffic, functional requirements, etc.

Since continuing the supports at the same distance is neither economical nor sensible, the distance between supports is reduced by constructing transfer floors.

The transfer floor could be a series of deep bars connected together or as flat slab (thick concrete slab).

The supports that extend from the transfer floor are floating supports and load-bearing supports.

- In normal buildings

Even in a normal building, if we cannot continue to use the existing supports, even if it is a small building, we start with new supports made from beams.

It also serves as structural support and supports the load of structural elements.

Tension Columns

This category includes supports that, in addition to the stresses applied by bending, also absorb axial stress as a tensile force.

Tension brackets can be erected for a variety of reasons.

- If we cannot continue the support to the upper level and we can design supports beyond the upper level, we consider using tensile supports to absorb the axial tensile stresses.

- If we need space at ground level to accommodate services or meet other needs, we can build a tension column.

The following figure shows a tension support installed in a building.

Floating column design

The construction of a floating column must be done with great care. Furthermore, the detailing of the floating pillars must also be carried out in accordance with the structural design, as the design considerations must be reflected in the detailing.

Improper construction and detailing practices can result in: Column error .

The construction of floating pillars should be similar to other pillars. However, important aspects must be taken into consideration during construction.

- Compression column

Calculate the axial load carefully. To calculate the axial load, another option could be considered. For example, consider a floating column on a transfer floor. As the columns are supported by a thick slab of deep beams, their deformations affect the axial loads on the columns.

Therefore, to evaluate the axial load, the bearing condition of the pin in the plane of the transfer floor, the effects of three-dimensional actions, etc. must be taken into account.

The evaluation of calculation moments must also be carried out in a similar way.

Depending on the height of the column, the dimensions of the column must be categorized and designed in accordance with building codes.

- Sizing a tension column

In contrast to the compression column, the tension column is exposed to tensile stresses.

As concrete cannot absorb tensile stresses, this must be done through reinforcement.

Tensile stresses in concrete could be limited by increasing reinforcement.

Bracing supports as floating supports

Reinforcement supports are also floating supports that are used, for example, to prevent cracks in brick walls.

Generally, the area of a brick wall is limited to about 12 m 2 to avoid cracking due to thermal effects. If the area covered by concrete beams and frames is greater than 12 m 2 Reinforcement beams and supports are constructed that limit the brick wall with concrete elements.

Additionally, if necessary, reinforcing brackets are built to secure various elements.