In electrical engineering and infrastructure safety, the importance of earthing systems cannot be underestimated. These systems are often invisible, but extremely important. They play an important role in safely dissipating electrical currents into the ground, preventing potential hazards such as electric shock, fire and equipment damage. Understanding the fundamentals and different types of grounding systems is essential for any electrical installation or project. This article examines the complexities of grounding systems and examines their types, components, and importance in protecting personnel and equipment in various environments.

What is a grounding system?

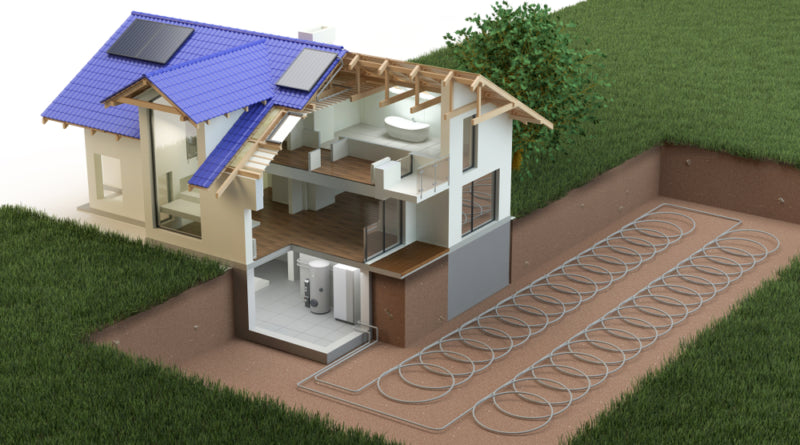

A grounding system, also called a grounding system, is a fundamental component of electrical systems and creates a low-resistance path for the safe conduction of electrical currents in the ground. It usually consists of conductive elements connected to electrical devices or systems, such as electrodes or grounding rods. By providing this connection to earth, grounding systems reduce the risk of electrical shock to people, prevent equipment damage from temporary power surges or lightning strikes, and ensure the overall stability and reliability of electrical systems. A grounding system serves as a protective measure, directing fault currents away from sensitive components and minimizing the potential for electrical hazards in various environments.

Components of a grounding system

To understand the intricacies of a grounding system, it is essential to familiarize yourself with its main components:

- Grounding electrode : This primary component makes contact with the earth. These can be bars, plates or strips of materials such as copper, galvanized steel or stainless steel.

- Grounding Conductor : These conductive cables or wires connect electrical systems, devices, or devices to the grounding electrode. Copper is often preferred due to its excellent conductivity and corrosion resistance.

- earth pit : A dug pit filled with a mixture of coal, salt and sand or a chemical compound to improve the conductivity of the soil around the earth electrode.

- earth strip : Large metal strips or grids provide a robust grounding network in industrial environments, especially in areas with high fault currents or lightning-prone environments.

Types of Grounding Systems

Grounding systems vary in design and configuration, each tailored to specific applications and environments. Understanding the different types of grounding systems is critical to ensuring optimal safety and performance in electrical systems. Below are some common types:

TN-S system

The TN-S system, the separate ground and neutral system, is commonly used in residential and commercial installations. In this configuration, separate conductors provide protective earth (PE) and neutral (N). The ground conductor is connected directly to the ground electrode, ensuring a low impedance path for fault currents. This system is recognized for its simplicity and effectiveness in dissipating residual currents from sensitive equipment and minimizing the risk of electric shock to people.

TT System

The TT system or multiple grounding neutral system is characterized by individual connections of electrical devices or systems to the grounding wire. Unlike the TN-S system, where multiple systems share a common ground, each device in the TT system has its own ground connection. Although this approach provides greater safety and isolation, especially in areas with unreliable ground connections or high fault currents, its implementation can be more complex and expensive due to the need for multiple ground wires.

IT System

In critical infrastructures such as hospitals, data centers and industrial facilities, ungrounded or isolated IT or systems are widely used. In this configuration there is an intentional separation between the power supply and the ground network. Although circuits operate without a direct connection to ground, monitoring devices detect any insulation failures or ground fault currents. The IT system offers a high level of protection against electrical shock and equipment damage, making it ideal for applications where uninterrupted power supply and safety are of utmost importance.

Importance of grounding systems

Grounding systems are extremely important because they serve a variety of purposes, including:

- Electric shock protection : Grounding systems provide a low-resistance path to the earth and direct fault currents away from people. This prevents potentially fatal electrical shocks.

- Equipment safety and longevity : Proper grounding reduces the risk of equipment damage from temporary power surges, lightning strikes, or electrical failures, extending the life of electrical equipment and infrastructure.

- Fire protection : In the event of a failure, effective dissipation of residual currents prevents overheating of conductors and insulation and significantly reduces the risk of electrical fire.

- Regulatory compliance : Compliance with national and international standards for grounding systems is critical to ensuring the safety and reliability of electrical systems and thus avoiding legal consequences and liabilities.

Conclusion

In short, grounding systems are the unsung heroes of electrical safety, quietly ensuring the stability and reliability of electrical systems across multiple industries and applications. From the simplicity of the TN-S system to the increased security of the IT system, each configuration plays a critical role in mitigating electrical risks and protecting lives and assets. By understanding the different types, components and measures to improve effectiveness, stakeholders can make informed decisions to ensure optimal safety and efficiency of electrical infrastructure. As technology advances and new challenges emerge, the importance of robust earthing systems remains unchanged, underlining their indispensable role in the modern world of electrical engineering.

Common questions

Why is proper grounding system maintenance so important?

Proper maintenance ensures the continued effectiveness of the grounding system, as wear and tear over time can degrade its performance. Regular inspections, testing and corrective actions, such as soil improvement or electrode replacement, are necessary to maintain low-impedance paths and compliance with safety standards.

Can improper grounding cause equipment damage?

Improper grounding can cause equipment damage due to transient voltage spikes or residual currents. A lightning strike or electrical failure can result in insulation damage, component failure, or even catastrophic damage if there is no reliable way to dissipate excess electrical energy.

How can we improve the effectiveness of grounding systems in rocky or sandy soils?

In difficult soil conditions, such as rocky or sandy terrain with low conductivity, chemical soil amendments, increasing electrode surface area, and using special drilling techniques can improve the effectiveness of the grounding system. These steps improve soil conductivity, ensure a reliable connection, and reduce electrical hazards.