STEEL IN THE BRAZILIAN INDUSTRY

Plasma Cutting Machine: Your Complete Guide for...

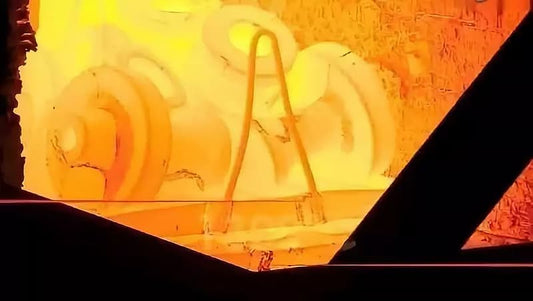

What is plasma cutting? Plasma cutting is a processing method that uses heat from a high-temperature plasma arc to partially or completely melt and evaporate metal in the cut piece.

Plasma Cutting Machine: Your Complete Guide for...

What is plasma cutting? Plasma cutting is a processing method that uses heat from a high-temperature plasma arc to partially or completely melt and evaporate metal in the cut piece.

Understanding the principle of plasma cutting m...

Modern industry requires the processing of heavy metals and alloys, and the manufacture of tools and transport vehicles necessary for daily activities cannot be separated from metals. Dust...

Understanding the principle of plasma cutting m...

Modern industry requires the processing of heavy metals and alloys, and the manufacture of tools and transport vehicles necessary for daily activities cannot be separated from metals. Dust...

Plate laminating machine: your definitive guide

Overview Plate rolling machine is a type of equipment that uses work rolls to bend and shape sheet metal into various shapes, including cylindrical and conical shapes. It's a p...

Plate laminating machine: your definitive guide

Overview Plate rolling machine is a type of equipment that uses work rolls to bend and shape sheet metal into various shapes, including cylindrical and conical shapes. It's a p...

Polishing: essential techniques explained

1. Polishing methods At present, the commonly used polishing methods are as follows: 1.1 Mechanical Polishing Mechanical polishing depends on the cutting and plastic deformation of the surface...

Polishing: essential techniques explained

1. Polishing methods At present, the commonly used polishing methods are as follows: 1.1 Mechanical Polishing Mechanical polishing depends on the cutting and plastic deformation of the surface...

Post-weld heat treatment: pros and cons

Welding residual stress is caused by uneven temperature distribution in the welded parts, thermal expansion and contraction of weld metal, etc., therefore, the associated welding construction...

Post-weld heat treatment: pros and cons

Welding residual stress is caused by uneven temperature distribution in the welded parts, thermal expansion and contraction of weld metal, etc., therefore, the associated welding construction...

Post-Welding Treatment of Aluminum and Aluminum...

I. Residue Removal After welding the workpiece, if gas welding or flux-cored welding rods are used, it is necessary to immediately clean the residual flux and slag from the...

Post-Welding Treatment of Aluminum and Aluminum...

I. Residue Removal After welding the workpiece, if gas welding or flux-cored welding rods are used, it is necessary to immediately clean the residual flux and slag from the...