STEEL IN THE BRAZILIAN INDUSTRY

Choosing the Right Cutting Parameters for CNC P...

The selection of cutting process parameters for CNC plasma cutting machines is crucial to the quality, speed and efficiency of cutting results. To correctly use a machine...

Choosing the Right Cutting Parameters for CNC P...

The selection of cutting process parameters for CNC plasma cutting machines is crucial to the quality, speed and efficiency of cutting results. To correctly use a machine...

Metal Forming: The Definitive Guide

Deformation characteristics of round hole flange: The deformation is local and mainly occurs in the annular part (d1-d0) at the bottom of the punch. This area is the flange deformation...

Metal Forming: The Definitive Guide

Deformation characteristics of round hole flange: The deformation is local and mainly occurs in the annular part (d1-d0) at the bottom of the punch. This area is the flange deformation...

Metal Forming: The Definitive Guide

Hold Flagging Hole flanging is a punching method that uses a die to transform the hole edge of the part into a vertical or straight edge at a certain angle....

Metal Forming: The Definitive Guide

Hold Flagging Hole flanging is a punching method that uses a die to transform the hole edge of the part into a vertical or straight edge at a certain angle....

Metal Stamping and Die Design: The Ultimate Guide

1.1 Characteristics and applications of the metal stamping process Definition of stamping From the concept of stamping: (1) Stamping is carried out at room temperature, that is, it does not...

Metal Stamping and Die Design: The Ultimate Guide

1.1 Characteristics and applications of the metal stamping process Definition of stamping From the concept of stamping: (1) Stamping is carried out at room temperature, that is, it does not...

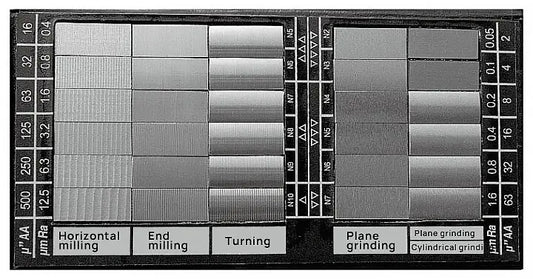

Roughness defects on metal surfaces: causes and...

Surface roughness is normally caused by several factors, including the processing method, friction between the tool and the workpiece surface during processing, plastic deformation...

Roughness defects on metal surfaces: causes and...

Surface roughness is normally caused by several factors, including the processing method, friction between the tool and the workpiece surface during processing, plastic deformation...

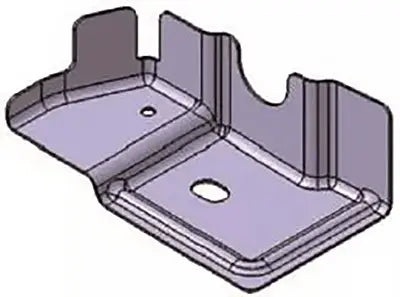

Reducing Stamping Production Cost: Research on ...

With the vigorous development of the automobile industry, competition between automobile companies is intensifying. Reduce vehicle manufacturing costs and improve efficiency...

Reducing Stamping Production Cost: Research on ...

With the vigorous development of the automobile industry, competition between automobile companies is intensifying. Reduce vehicle manufacturing costs and improve efficiency...