STEEL IN THE BRAZILIAN INDUSTRY

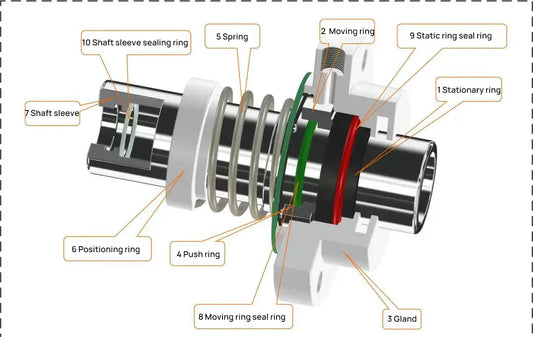

Understanding Mechanical Seals: A Must-Read Guide

Leakage is one of the common failures in mechanical equipment. The reasons for causing leaks are mainly two: firstly, they are caused by machining, and the surface of products...

Understanding Mechanical Seals: A Must-Read Guide

Leakage is one of the common failures in mechanical equipment. The reasons for causing leaks are mainly two: firstly, they are caused by machining, and the surface of products...

Data Analysis: Surface Roughness of Mirror Stai...

The term “mirror stainless steel plate” refers to the surface finish of the steel, but it also comes in different grades. This class refers to the surface roughness of stainless...

Data Analysis: Surface Roughness of Mirror Stai...

The term “mirror stainless steel plate” refers to the surface finish of the steel, but it also comes in different grades. This class refers to the surface roughness of stainless...

Fingerprint Resistant Stainless Steel Plate: Be...

The fingerprint-resistant stainless steel plate is easy to clean, why? We know that if ordinary stainless steel plate is pressed by hand, it will leave obvious marks on the surface...

Fingerprint Resistant Stainless Steel Plate: Be...

The fingerprint-resistant stainless steel plate is easy to clean, why? We know that if ordinary stainless steel plate is pressed by hand, it will leave obvious marks on the surface...

1Cr13 x 2Cr13 x 3Cr13 x 4Cr13: Which is best fo...

Martensitic stainless steel is a type of stainless steel that can have its properties changed through heat treatment processes such as quenching and tempering, making it a stainless steel and...

1Cr13 x 2Cr13 x 3Cr13 x 4Cr13: Which is best fo...

Martensitic stainless steel is a type of stainless steel that can have its properties changed through heat treatment processes such as quenching and tempering, making it a stainless steel and...

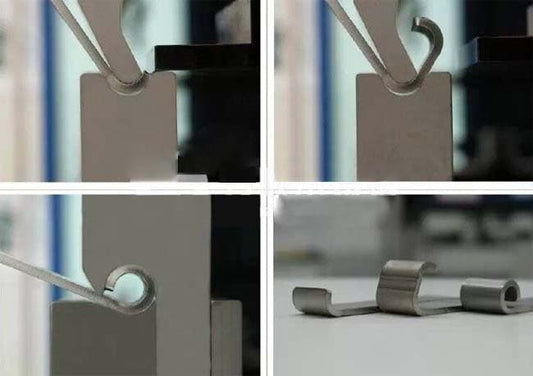

Essential Precautions for Safe Arc Bending Proc...

Sheet metal arc bending processing: arc processing can be divided into common tool processing or arc tool processing (radius punch and steel punch).

Essential Precautions for Safe Arc Bending Proc...

Sheet metal arc bending processing: arc processing can be divided into common tool processing or arc tool processing (radius punch and steel punch).

5 Basics of 316L Stainless Steel

1. Chemical composition of 316L C stainless steel: ≤ 0.03%; Si: ≤ 0.75%; Mn: ≤ 2.00%; S: ≤ 0.030%; P: ≤ 0.045%; Cr: 16.00~18.0%; Ni: 10.00-14.00%; Mo: 2.00~3.00%; N: 0.10%....

5 Basics of 316L Stainless Steel

1. Chemical composition of 316L C stainless steel: ≤ 0.03%; Si: ≤ 0.75%; Mn: ≤ 2.00%; S: ≤ 0.030%; P: ≤ 0.045%; Cr: 16.00~18.0%; Ni: 10.00-14.00%; Mo: 2.00~3.00%; N: 0.10%....