STEEL IN THE BRAZILIAN INDUSTRY

4 common part errors and their causes in CNC mi...

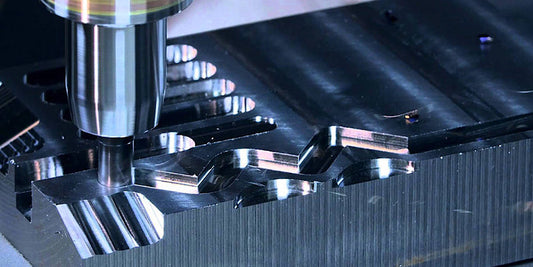

CNC milling is one of the most commonly used part machining methods when you need to produce a high-precision part. Modern CNC milling tools offer great opportunities...

4 common part errors and their causes in CNC mi...

CNC milling is one of the most commonly used part machining methods when you need to produce a high-precision part. Modern CNC milling tools offer great opportunities...

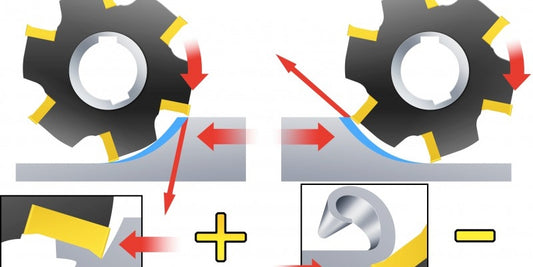

CNC Milling Tips: Learn When to Use Down Millin...

Experts use numerous CNC milling techniques to get the most out of their CNC machine, depending on the size, shape, features and material of the part being machined....

CNC Milling Tips: Learn When to Use Down Millin...

Experts use numerous CNC milling techniques to get the most out of their CNC machine, depending on the size, shape, features and material of the part being machined....

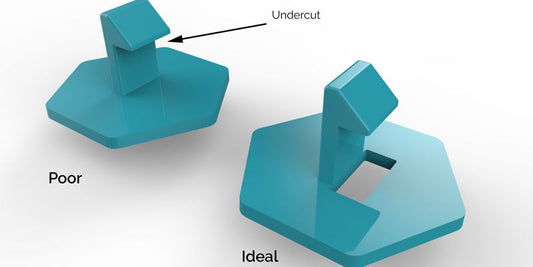

Successful use of undercuts in injection moldin...

Undercut injection molding is a process for producing parts with complex shapes and features that prevent the part from being removed from the mold without damage. The lower cut features...

Successful use of undercuts in injection moldin...

Undercut injection molding is a process for producing parts with complex shapes and features that prevent the part from being removed from the mold without damage. The lower cut features...

A Guide to CNC Milling of Curved Surfaces

Milling curved surfaces falls under the term CNC profile/contour milling. Irregularly shaped profiles or continuous curves with different degrees (oblique, concave...) are processed.

A Guide to CNC Milling of Curved Surfaces

Milling curved surfaces falls under the term CNC profile/contour milling. Irregularly shaped profiles or continuous curves with different degrees (oblique, concave...) are processed.

Thinning vs. machining finish: What are the dif...

In general, the basic principles of CNC machining include standard subtractive manufacturing operations such as turning, milling, facing, drilling, grooving, boring, etc. These processes involve...

Thinning vs. machining finish: What are the dif...

In general, the basic principles of CNC machining include standard subtractive manufacturing operations such as turning, milling, facing, drilling, grooving, boring, etc. These processes involve...

Aluminum 6061 vs. 7075: what is best for your p...

If you walk down the street, you will see many aluminum alloy products. They are among the most popular materials in the automotive, sports equipment, electrical, construction and aerospace industries...

Aluminum 6061 vs. 7075: what is best for your p...

If you walk down the street, you will see many aluminum alloy products. They are among the most popular materials in the automotive, sports equipment, electrical, construction and aerospace industries...