STEEL IN THE BRAZILIAN INDUSTRY

Cast Iron Brazing: Explained

1. Brazing Materials (1) Filler metals Copper-zinc filler metals and silver-copper filler metals are mainly used for brazing cast iron. The common grades of metal...

Cast Iron Brazing: Explained

1. Brazing Materials (1) Filler metals Copper-zinc filler metals and silver-copper filler metals are mainly used for brazing cast iron. The common grades of metal...

Brazing of tool steel and hard alloy: explained

1. Brazing Materials (1) Brazing Materials Pure copper, copper-zinc and silver-copper brazing materials are commonly used for brazing tool steel and hard alloys. The copper...

Brazing of tool steel and hard alloy: explained

1. Brazing Materials (1) Brazing Materials Pure copper, copper-zinc and silver-copper brazing materials are commonly used for brazing tool steel and hard alloys. The copper...

Brazing Carbon Steel and Low Alloy Steel: Expla...

1. Brazing Materials (1) Filler metals Brazing of carbon steel and low alloy steel includes soft brazing and hard brazing. The most commonly used filler metal in soft brazing is...

Brazing Carbon Steel and Low Alloy Steel: Expla...

1. Brazing Materials (1) Filler metals Brazing of carbon steel and low alloy steel includes soft brazing and hard brazing. The most commonly used filler metal in soft brazing is...

Welding flux: how to select and use correctly

Flux: chemical substance that can assist and promote the welding process in the welding process, has a protective effect and prevents oxidation reaction. Flow can be divided into solid, liquid...

Welding flux: how to select and use correctly

Flux: chemical substance that can assist and promote the welding process in the welding process, has a protective effect and prevents oxidation reaction. Flow can be divided into solid, liquid...

8 tips to reduce welding spatter

When a welding flame spatters, it often leaves welding spatter on the workpiece that must be removed, which takes time and money. It's best to avoid splashes, or at least...

8 tips to reduce welding spatter

When a welding flame spatters, it often leaves welding spatter on the workpiece that must be removed, which takes time and money. It's best to avoid splashes, or at least...

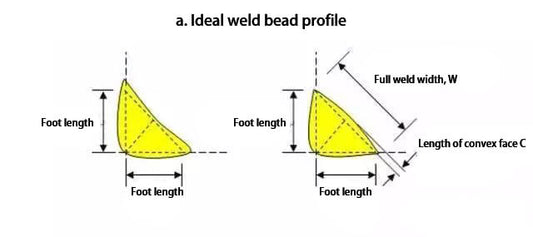

Qualified fillet welds: what type is acceptable?

When designing a weld, several factors must be taken into consideration, such as the weldability of the base metal, the match between the welding materials and the base metal, the...

Qualified fillet welds: what type is acceptable?

When designing a weld, several factors must be taken into consideration, such as the weldability of the base metal, the match between the welding materials and the base metal, the...