STEEL IN THE BRAZILIAN INDUSTRY

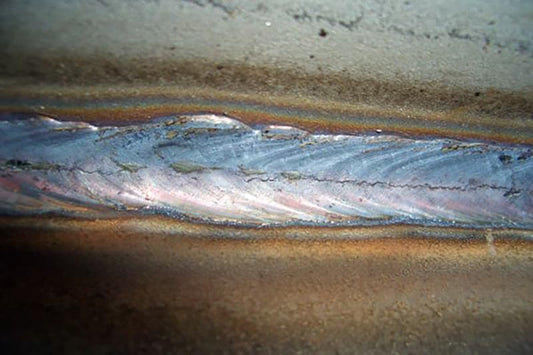

4 reasons for electrode sticking during welding

Sticky electrode refers to an abnormal welding between the electrode and the workpiece, causing the electrode to adhere to the workpiece. This can cause the electrode to be torn off...

4 reasons for electrode sticking during welding

Sticky electrode refers to an abnormal welding between the electrode and the workpiece, causing the electrode to adhere to the workpiece. This can cause the electrode to be torn off...

Basics of Inverter Type Arc Welding Power Supply

Inverter arc welding power source, also known as arc welding inverter, is a new type of welding power source. This type of power supply usually takes...

Basics of Inverter Type Arc Welding Power Supply

Inverter arc welding power source, also known as arc welding inverter, is a new type of welding power source. This type of power supply usually takes...

Friction Welding: Principles, Classification, P...

1. Principle of Friction Welding I. The Principle and Classification of Friction Welding (1) The Principle of Friction Welding Friction welding: It is a pressure welding method that uses...

Friction Welding: Principles, Classification, P...

1. Principle of Friction Welding I. The Principle and Classification of Friction Welding (1) The Principle of Friction Welding Friction welding: It is a pressure welding method that uses...

Eliminate Welding Residual Stress: 6 Effective ...

After the pressure vessel is welded, a residual stress is produced in the structural weld zone. This is because the uneven heating temperature field during welding causes...

Eliminate Welding Residual Stress: 6 Effective ...

After the pressure vessel is welded, a residual stress is produced in the structural weld zone. This is because the uneven heating temperature field during welding causes...

Brazing of high temperature alloys: explained

1. Brazing Characteristics High temperature alloys can be divided into three main categories: nickel-based, iron-based and cobalt-based. They exhibit good mechanical properties...

Brazing of high temperature alloys: explained

1. Brazing Characteristics High temperature alloys can be divided into three main categories: nickel-based, iron-based and cobalt-based. They exhibit good mechanical properties...

Stainless Steel Brazing: Explained

1. Brazing performance The main problem in brazing stainless steel is the presence of oxide films on the surface, which significantly affects the wettability and spreading of the metal...

Stainless Steel Brazing: Explained

1. Brazing performance The main problem in brazing stainless steel is the presence of oxide films on the surface, which significantly affects the wettability and spreading of the metal...