Choosing the right laser cutting nozzle doubles efficiency.

Although it may seem like a small and discreet piece, its role is not insignificant. It needs to resist the ricochet of molten debris and control the area and size of gas diffusion.

Therefore, the quality of the laser cutting head nozzle is one of the important factors that determine the quality of laser cutting. Today we will discuss how to choose the right nozzle.

I. Is there a big difference between nozzles of different qualities?

Yes, there is a significant difference, as the material and precision of the nozzle play a decisive role in the conductivity, thermal conductivity, difficulty of adjustment and protection of the laser head.

A good nozzle can protect the optical lens inside the cutting head and release auxiliary gas to the surface and crevice of the cutting material, directing the gas to assist in cutting and removing slag, leaving a clean cut.

Therefore, the quality of the nozzle directly affects the life of the cutting head and the quality of the part being cut.

Generally speaking, nozzles that come with the original shaving head are priced higher, which has made third-party nozzles very popular. However, not all third-party manufacturers have the production capacity for such consumables.

In the price war of fiber laser cutters in recent years, the prices of laser cutter accessories have also fallen. Blindly chasing low prices and ignoring quality will result in more harm than good.

II. What are the consequences of improper nozzle selection?

If the nozzle design and maintenance are not appropriate, the processing accuracy may be insufficient, resulting in a reduction in the gas flow rate and unstable air flow direction, which may affect the melting of materials during the process cutting edges and produce molten debris. Thicker materials may even become impossible to cut.

Selecting a very large nozzle

Rough top stripes with serrated edges (right)

Selecting a very small nozzle

III. What are the types of nozzles?

Currently, there are two main types of nozzle designs: “low-speed nozzle” (the gas flow rate is less than the speed of sound) and “high-speed nozzle” (the gas flow rate is close to the speed of sound).

Factors that affect nozzle performance include gas pressure in the cutting head cavity, nozzle diameter, nozzle internal shape, and nozzle exit shape.

The working principle of a high-speed nozzle is similar to the exhaust principle of a rocket or jet engine, which has an accelerating effect on the gas entering the nozzle. Therefore, a high speed nozzle can produce better cutting results for viscous materials.

If a regular low-speed nozzle is used, the surface pressure of the workpiece will fluctuate significantly as the cutting height changes, which may lead to unsatisfactory cutting results.

4. How to select a nozzle?

Laser cutting is currently recognized as one of the most efficient, precise and high-quality methods of metal processing.

Several factors affect laser cutting, and the nozzle is one of them. Selecting the appropriate nozzle when cutting different materials can simplify processing. But how can we correctly choose the right nozzle? Let's take a look today.

The nozzle, also known as the copper nozzle, is one of the very important components in laser cutting. Located at the lower end of the cutting head, both the laser beam and the auxiliary gas act on the cutting material through the nozzle. Its main function is to gather auxiliary gas and form high pressure, releasing it on the surface and cutting of the cutting material.

This removes the original material that melted and vaporized during the cutting process, leaving a clean cut. At the same time, it prevents pollutants such as molten slag and dust from returning upward, thus protecting the internal lens.

To obtain better cutting sections, it is necessary to control the concentricity of the laser beam and the center of the nozzle, which is one of the important factors affecting the cutting quality. Therefore, the nozzle must be coaxial with the laser beam to obtain better cutting sections.

When the nozzle center and the laser beam center are not coaxial, the effects on cutting quality are as follows:

- The cutting gas is sprayed from the center of the nozzle, which is the center point where the plate needs to be cut. If the laser is not in the center of the nozzle, there will be a deviation between the laser's action point and the actual one, leading to a noticeable inconsistency between the actual cut and the expected effect.

- If the laser is not in the center of the nozzle, the beam will hit the inner wall of the nozzle during normal operation, which may seriously burn the nozzle and affect the actual cutting effect.

To check whether the laser beam and nozzle are coaxial, the following steps are required for testing:

- Stick a piece of clear tape over the nozzle opening, with the circular edge completely overlapping the tape;

- Adjust the power of the device to about 100 W and use the point shooting mode to irradiate the transparent tape with the laser;

- Remove the transparent tape and observe the relationship between the circular edge and the position of the laser hole.

If the hole is in the center of the circle, it means that the laser beam and nozzle are coaxial and no adjustment is necessary. If the hole is not coaxial with the center of the circle, or if the hole cannot be seen (the laser beam hits the inside wall of the nozzle), you will need to adjust the adjustment screw on the laser cutting head. Repeat steps 1 to 3 until the laser hole coincides with the center of the nozzle.

Nozzle type selection:

Nozzles are divided into single-layer and double-layer nozzles. Single layer nozzles have relatively slow gas flow speeds and are commonly used to cut metals such as stainless steel, aluminum alloy and copper, often using nitrogen as the auxiliary gas.

Double-layer nozzles have fast gas flow speeds, suitable for high-speed cutting, and are often used to cut carbon steel, generally using oxygen as the auxiliary gas, and the cutting surface often turns black due to oxidation.

Nozzle size selection:

The size of the nozzle opening determines the speed of the gas flow that acts on the cutting material, thus affecting the removal of molten material. The greater and faster the air flow entering the cut, the greater the ability to blow the molten material.

In theory, the thicker the plate, the larger the nozzle should be used. However, the larger the nozzle opening, the greater the chance of molten material splashing upwards during cutting, which shortens the life of the lens.

Deformed or melted nozzles will affect the cutting effect. Therefore, the nozzle must be handled with care to avoid impact or deformation, and any melted drops on the nozzle must be wiped off immediately.

Factors to consider when selecting a nozzle :

There are several factors to consider when selecting a nozzle:

Processing needs: Single-layer nozzles used in laser equipment are mainly used to cut stainless steel and aluminum plates with nitrogen, while double-layer nozzles are mainly used to cut carbon steel with oxygen.

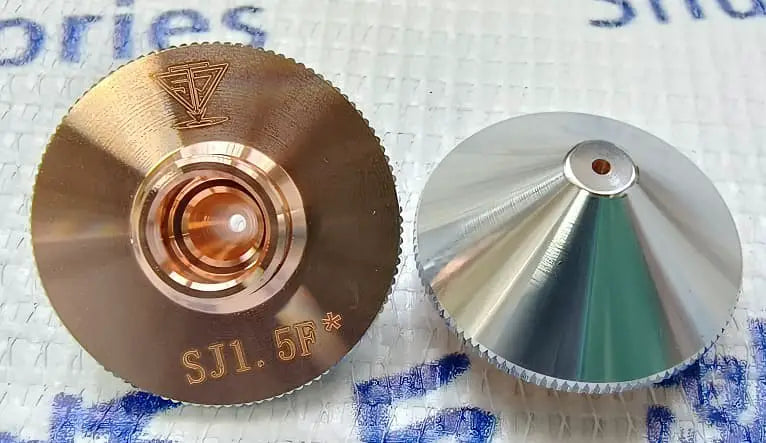

Material: Nozzles are commonly made of two materials, purple copper and brass. Purple copper has better conductivity and thermal performance than brass.

Size: The size of the nozzle opening determines the gas flow rate and the shape of the gas field. Generally, when cutting sheets below 3 mm, it is recommended to use a nozzle with a diameter of 1 mm, and for 3 mm or more, a nozzle with a diameter of 1.5 mm is recommended. For cuts above 10 mm, a nozzle with a diameter equal to or greater than 2 mm is recommended.

Processing accuracy: A good laser head nozzle should have a concentricity of 0.03mm, while nozzles with a size of 1.0mm or less should have a concentricity of 0.02mm or better. Nozzles with high-precision concentricity not only reduce the initial clearance during processing, but also effectively prevent damage to the laser head caused by the high-energy laser hitting the inner wall of the head.

V. Introduction to Common Nozzles

There are several types of nozzles commonly used in industrial applications. Here are some of the most common:

Single Layer Nozzle – S

Features: Conical internal wall with high gas flow for slag blowing.

Purpose: Fusion cutting of materials such as stainless steel and aluminum sheet.

Double Layer Nozzle – D

Features: Dual layer composite nozzle with an added inner core based on a single layer nozzle.

Purpose: Double layer 2.0 or greater for carbon steel sand cutting

High Speed Double Layer Nozzle – E

Features: The nozzle is pointed in shape, and the three holes on the edge of the inner core are larger than those of a normal double-layer nozzle.

Purpose: It is mainly used for high-power, high-speed and high-quality cutting of carbon steel up to 20mm thick with smooth and bright surface finish.

High Speed Single Layer Nozzle – SP

Characteristics: The nozzle has a pointed shape, with a conical inner wall that has a stepped design.

Purpose: It is mainly used for high-power and high-speed cutting of carbon steel with a thickness above 20mm, resulting in a smooth and bright surface finish. It is also suitable for oxygen-focused cutting applications.

High Speed Single Layer Nozzle – SD

Features: The nozzle has a pointed shape with a conical inner wall and a larger nozzle orifice area.

Purpose: It is mainly used for high-speed cutting of carbon steel with a thickness above 20mm, resulting in smooth and stable cutting performance with better cutting quality.

Reinforcement nozzle – B

Features: Improved from a single layer nozzle, the nozzle has a stepped layer at the nozzle hole.

Purpose: It can be used for high-power cutting of stainless steel and carbon steel with nitrogen or compressed air at low pressure.

SAW. How to install and adjust a nozzle?

Nozzle installation steps:

- Unscrew the old nozzle.

- Install the new nozzle and tighten it with the appropriate force.

- After replacing the nozzle, recalibrate the capacitance.

For example, for a 12 kW BLT laser cutting head with a focal point paired with a nozzle (focal point 0 must be calibrated):

- 1.2E double layer nozzle: for cutting 3mm to 12mm carbon steel plate, focal points between 5-11.

- 1.4E double layer nozzle: focal points between 9-14.

- 1.6E double layer nozzle: focal points between 11-16.

- 1.8E double layer nozzle: focal points between 13-18.

- Single layer SP nozzle 1.2: focal points between 8-13.

- Single layer SP nozzle 1.4: focal points between 10-15.

- Single layer SP nozzle 1.6: focal points between 12-17.

- Single layer SP nozzle 1.8: focal points between 14-19.

It is important to properly install and calibrate the nozzle to ensure optimal performance and cutting quality.

VII. Recommendations for Common Nozzles

| Laser | Cutting thickness (bright surface cutting of carbon steel with oxygen) | Suggested mouthpiece |

|---|---|---|

| Low power laser (≤6000W) | 16-20mm | General conical nozzle 1.4D-1.6D |

| High power laser (≥6000W, using Raycus 12kW as an example) | 3-12mm | 1.2E Double Layer High Speed Nozzle |

| 12-14mm | 1.2B-1.4E Double Layer High Speed Nozzle | |

| 16-20mm | 1.4E-1.6E Double Layer High Speed Nozzle | |

| 22-35mm | SP1.4-SP1.8 Single Layer High Speed Nozzle or 1.4E-1.8E Double Layer High Speed Nozzle |

|

| 35-40mm | SP1.6-SP1.8 Single Layer High Speed Nozzle or 1.6E-1.8E Double Layer High Speed Nozzle |

The quality of nozzles on the market varies greatly. It is recommended to carefully distinguish them according to the above content and purchase through regular channels.