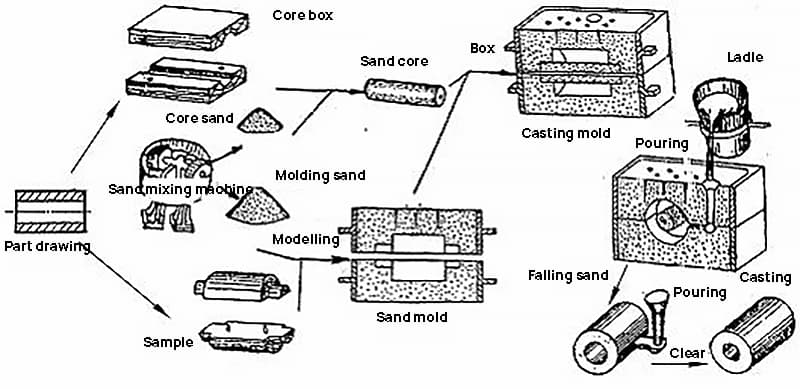

Casting production process

The production of castings is a complex multi-step process covering the following main processes:

- Production process preparation: involves creating a production process plan and related documents, as well as developing casting process drawings based on part drawings, production batch, and expected delivery date.

- Preparation of production materials: This includes the preparation of materials for melting, as well as the materials and patterns required for molding and core manufacturing, such as core boxes, sand boxes, and other equipment.

- Core Molding and Manufacturing;

- Melting and Spilling;

- Key processes including sand disposal and casting inspection.

See too:

- 14 different types of casting process

Casting manufacturing process

The casting process involves melting metal or alloy and pouring it into a mold for cooling and solidification.

The production of castings is a complex process involving several steps, including the preparation of metallic and non-metallic materials, alloy melting, molding, core making, casting, cleaning, defect correction, heat treatment and obtaining qualified castings. .

The casting manufacturing process can be divided into the following main steps: molding and core sand preparation, shaping, casting, sand mold drying, pouring, cleaning and heat treatment of the casting.

1. Preparation of molding sand and core sand

The quality of molding sand is directly influenced by its preparation process.

Typically, molding sand preparation involves two steps: raw material preparation and checking, followed by molding sand preparation and quality control.

2. Modeling

Molding refers to the process of creating a sand mold using molding sand, a pattern and other technological equipment.

There are several molding techniques, which are determined by the shape, size and technical specifications of the casting.

3. Casting

Smelting is the process of converting metal from a solid to a liquid state by heating and removing impurities through metallurgical reactions in order to achieve the desired temperature and compositional requirements.

There are several types of casting equipment available. For the production of cast iron platforms, a Cupola furnace is typically used for machine tool castings.

4. Drying of sand mold

Dry casting is a commonly used method for producing large or high-quality castings, such as cast iron platforms, machine tool castings, machine tool workbenches, and other types of machine tool castings.

5. Pouring

The operation of injecting molten metal from the shell into the mold is called casting.

6. Cleaning

The process of removing surface-adherent sand, molding sand, and excess metal from the casting after the sand has fallen is called cleaning.

7. Casting heat treatment

Heat treatment for castings includes heating the casting to a specific temperature range, holding it for a certain period, and then cooling it at a specified rate to achieve the desired structure and properties.

The purpose of heat treatment for castings is to relieve stress from the casting. For example, cast iron platforms, machine tool castings, and machine tool benches need to undergo heat treatment before being further processed.

Formation principle

Casting production is a metal forming technique that involves heating the metal to bring it to a fluid state and pouring it into a mold of the desired shape. The metal fills the mold cavity under the influence of gravity or external forces such as pressure, centrifugal force or electromagnetic force, and then cools and solidifies into a casting or part.

Fig. 1 casting process

The casting process generally involves transforming a blank into a part.

However, some castings meet the necessary requirements for design accuracy and surface roughness without the need for additional cutting and can be used directly as parts.

Properties and composition of molding sand

1. Properties of molding sand

The main performance criteria for molding sand (including core sand) include strength, permeability, fire resistance, yield, fluidity, compaction and ability to resist collapse.

2. Composition of molding sand

Molding sand is composed of raw sand, binder and additives.

The raw sand used in casting should be sea sand, river sand or mountain sand with low mud content, uniform particle size and a mixture of round and polygonal shapes.

Adhesives used in casting include clay (such as common clay and bentonite), water-soluble glass sand, resin, synthetic oil, and vegetable oil, which are called clay sand, water-soluble glass sand, resinous sand, synthetic oil sand, and oil vegetable. sand, respectively.

To improve the specific properties of mold (core) sand, additives such as charcoal, sawdust and cellulose are sometimes added to the mold (core) sand.

The structure of the molding sand is illustrated in Figure 2.

Fig. 2 Schematic diagram of the molding sand structure

Features of the casting process

Casting is an important method of producing blanks, especially for parts made from brittle metals or alloys (such as various castings of cast iron and non-ferrous alloys), where casting is often the only manufacturing process available.

Compared to other manufacturing methods, casting has the following distinct characteristics:

- Versatility in material, size and weight:

- The casting process can be applied to a wide range of materials, including cast iron, cast steel, aluminum alloy, copper alloy, magnesium alloy, titanium alloy, zinc alloy and various special alloys.

- Castings can range from a few grams to hundreds of tons in weight.

- The wall thickness of castings can be from 0.5 mm to approximately 1 m.

- The length of castings can vary from a few millimeters to ten meters.

- Ability to produce complex shapes:

- Cast parts can be made in all types of shapes, especially for parts with complex internal cavities, such as boxes, cylinders, blades, impellers, among others.

- Approximate correspondence to the shape and size of the final product:

- The shape and size of castings can be very similar to the final parts, which not only conserves material but also reduces machining time.

- Accessibility and availability of raw materials:

- The raw materials used for casting are readily available and the cost of casting is relatively low.

- Flexibility and high productivity:

- The casting process can be carried out manually or by mechanical methods, which makes it highly flexible.

- The productivity of the casting process is high.

Analysis of common defects in casting

The casting process is complex and the quality of castings can be affected by a number of factors.

Frequent occurrences of casting defects result from poor control of raw materials, inadequate process planning, inadequate production operations and insufficient management systems.

The following is a list of common casting defects, along with their names, characteristics and causes.

| Defect name | characteristics | Main causes |

Stomach

|

There are smooth holes of different sizes inside or on the surface of the casting. | ① The furnace charge is not dry or contains many oxides and impurities; ② Pouring tools or additives in front of the furnace do not dry out; ③ Too much water is contained in the molding sand or too much water is brushed off during mold lifting and cutting; ④ Insufficient core drying or blocked core ventilation; ⑤ Spring sand is very compact and the air permeability of molding sand is low; ⑥ The pouring temperature is too low or the pouring speed is too fast. |

| Shrinkage cavity and porosity |

The shrinkage holes are mainly distributed in the thick section of the casting, with an irregular shape and a rough interior. | ① The structural design of the casting is unreasonable, for example, the wall thickness difference is too large, and no riser or cold iron is placed on the thick wall; ② The position of the leakage system and riser is wrong; ③ The pouring temperature is too high; ④ The chemical composition of the alloy is unqualified, the shrinkage rate is too large, and the riser is too small or small. |

Sand holes

|

There are holes filled with molding sand inside or on the surface of the casting. | ① The strength of the molding sand is too low or the compaction of the sand mold and core is not sufficient, so the molding sand is poured into the mold cavity by the molten metal; ② The sand mold is partially damaged when the box is closed; ③ The pouring system is unreasonable, the input direction is wrong, and the sand mold is damaged by molten metal; ④ Loose sand in the mold cavity or gate is not cleaned when the box is closed. |

Sticky sand

|

The surface of the casting is roughened with a layer of sand. | ① The fire resistance of raw sand is low or the particle size is too large; ② The fire resistance of molding sand decreases when the mud content is too high; ③ The pouring temperature is too high; ④ The pulverized coal content in the molding sand is very small in the green casting process; ⑤ The dry type is not painted obliquely or the coating is too thin. |

Sand inclusion

|

A layer of molding sand is placed between the sheet metal protrusion and the coupling part. | ① The hot and wet tensile strength of molding sand is low, and the surface of the mold cavity is heated and baked to expand and crack; ② The local compaction of the sand mold is too high, the water is too much, and the surface of the mold cavity is cracked after the water is dried ten times; ③ Improper selection of pouring position causes the cavity surface to expand and crack due to prolonged cooking of cast iron at high temperature; ④ The pouring temperature is too high and the pouring speed is too slow. |

Wrong type

|

The casting has relative displacement along the parting surface. | ① The upper half of the pattern mold and the lower half of the pattern mold are not aligned; ② When the box is closed, the upper and lower litter boxes are misaligned; ③ The upper and lower sandboxes are not fixed, or the upper box is not pressed enough and the wrong box is generated during pouring. |

cold barrier

|

There are gaps or holes in the casting where the cards are completely fused and the joints are smooth. | ① The pouring temperature is too low and the fluidity of the alloy is low; ② The pouring speed is too slow or the flow is interrupted during pouring; ③ The position of the leakage system is inappropriate or the cross-sectional area of the gate is too small; ④ The casting wall is very thin; ⑤ The height of the sprue (including the sprue cup) is insufficient; ⑥ When leaking, the amount of metal is insufficient and the cavity is not full. |

Insufficient spillage

|

The cast is not completely filled. | |

To snap

|

The casting is cracked and there is an oxide film on the metal surface in the crack. | ① The casting structure design is unreasonable, the wall thickness difference is too large, and the cooling is uneven; ② The indentation of the sand mold and core is poor or the spring sand is too compact; ③ Premature sand fall; ④ Improper position of the gate leads to uneven shrinkage of all parts of the casting. |

Common casting defects and their preventive measures

| Order | Defect title | Defect characteristics | Preventive measure |

| 1 | stoma | Inside, on the surface or close to the surface of the casting, there are smooth holes of different sizes. The shapes are round, long and irregular, simple or aggregated. The color is white or dark, sometimes covered with an oxide layer. | Reduce the amount of metal during casting. Reduce gas emission from the sand mold during the casting process, improve the casting structure, improve the permeability of the sand mold and core, and allow the gas in the mold to be discharged smoothly. |

| two | contraction cavities | Within the thick section of the casting, the interior of the two interfaces and the interior or surface of the junction of the thick section and the thin section, the shape is irregular, the hole is rough and irregular, and the grain is coarse. | Castings with small and uniform wall thickness must be solidified at the same time. Castings with large and uneven wall thickness should be solidified from thin to thick, and the cold riser iron should be placed reasonably. |

| 3 | shrinkage porosity | The small, discontinuous shrinkage holes in the casting are gathered in one or more places and the particles are coarse. There are small holes between each particle and water infiltration occurs during hydrostatic testing. | Hot joints should be minimized at the joints between walls, and the temperature and leakage speed should be minimized. |

| 4 | slag vent | Irregularly shaped holes in the interior or surface of the casting. The holes are not smooth and filled with slag in whole or in part. | Increase the temperature of the cast iron.Reduce the viscosity of the slag.Improve the slag retention capacity of the channel system.Increase the internal fillet of the casting. |

| 5 | sand holes | There are holes filled with molding sand inside or on the surface of the casting. | Strictly control the performance of the molding sand and the molding operation, and pay attention to cleaning the mold cavity before closing the mold. |

| 6 | thermal cracking | There are penetrating or non-penetrating cracks in the casting (Note: if it is curved) and the metal film in the crack is oxidized. | Strictly control the S and P content in cast iron. The wall thickness of the casting should be as uniform as possible. wall thickness. Opening cannot be too early. Castings cannot be tempered. |

| 7 | cold crack | There are penetrating or non-penetrating cracks (mostly straight) in the casting, and the metal film in the crack is oxidized. | |

| 8 | sand burning | The surface of the casting is completely or partially covered by a layer of metal (or metal oxide) mixed with sand (or coating) or a layer of sintered molding sand, resulting in a rough surface of the casting. | Reduce the sand gap. The metal pouring temperature must be reduced accordingly. Improve the fire resistance of molding sand and core sand. |

| 9 | sand inclusion | On the surface of the casting, there is a layer of metal tumor or foil, and a layer of molding sand is sandwiched between the metal tumor and the casting. | Strictly control the properties of molding sand and core sand. Improve the pouring system to make the molten metal flow smoothly. |

| 10 | cold barrier | There is a kind of incomplete fusion gap or pit in the casting, and its edge is smooth. | Improve temperature and pouring speed. Improve the gate system. The flow must not be interrupted during pouring. |

| 11 | unable to spill | Lack of pulp in the casting due to incomplete filling of the cavity with molten metal. | Improve pouring temperature and speed. Do not interrupt the flow and avoid fire. |

Casting – molten metal casting

During casting in production, it is important to follow the principle of high temperature casting and low temperature casting.

Increasing the pouring temperature of molten metal promotes complete melting of inclusions and floating of molten slag, facilitating cleaning and degassing and reducing the likelihood of slag inclusion and porosity defects in castings.

On the other hand, a lower pouring temperature helps to decrease gas solubility, liquid shrinkage and surface baking of molten metal at high temperature in the mold cavity, avoiding defects such as porosity, sand adhesion and shrinkage.

Therefore, the pouring temperature must be kept as low as possible while ensuring that the mold cavity is completely filled.

Casting involves the operation of transferring molten metal from the ladle to the mold. Improper casting can result in casting defects such as insufficient casting, cold shutting, air holes, shrinkage holes, and slag inclusion, as well as pose a risk of personal injury.

To ensure casting quality, improve productivity and achieve safe production, the following guidelines must be strictly followed during casting:

(1) Make sure the ladle, pouring tool, inoculant and spheroidizing agent used in furnace pretreatment are completely dry before use.

(2) Personnel carrying out pouring must wear suitable work clothes and protective glasses, and the work area must be free from obstacles.

(3) The molten metal in the casting ladle should not be too full to avoid spillage and injury during transportation and casting.

(4) Select the pouring speed appropriately, starting slowly to align the gate, reduce the impact of molten metal on the sand mold, and facilitate gas discharge. Pour quickly to avoid cold isolation, then slowly again before pouring completely, following the principle of “slow, fast, slow.”

(5) For parts with high liquid shrinkage and solidification shrinkage, such as medium and large steel parts, casting should be carried out through the gate or riser after casting is completed.

(6) Ignite any gas emitted by the casting mold during casting to avoid gas holes and minimize health damage and air pollution due to incomplete combustion of the gas.

8 Basic Sand Casting Steps

Sand casting technology is a casting method that uses sand as the primary material for mold preparation.

Sand casting is a tried and true casting method that has been used for centuries.

Despite its age, sand casting remains the most widely used casting method, particularly for single pieces or small batches, due to its versatility in accommodating a wide range of shapes, sizes, complexities and alloys, as well as its cycle short production period and low cost. cost.

The traditional sand casting process consists of the following steps: sand preparation, mold making, core making, molding, casting, sand removal, grinding and inspection.

1. Sand mixing stage

Molding sand and core sand are prepared for the molding process.

Typically, a sand mixer is used to mix the used sand with the appropriate amount of clay.

2. Mold making stage

Molds and male boxes are created based on part drawings. Single pieces are typically made in wooden molds, while mass production may utilize plastic or metal molds, also known as iron or steel molds.

For high volume production, molds can be made using jigs.

With the use of engraving machines, the mold making process became much faster, reducing the production cycle to 2 to 10 days.

3. Molding stage (core manufacturing)

The molding process involves forming the mold cavity of the casting using molding sand. Core manufacturing involves creating the internal shape of the casting, and mold matching involves placing the core into the mold cavity and sealing it with the upper and lower sandboxes.

Molding is a crucial step in the casting process.

4. Fusion stage

To produce the desired metallic composition, the chemical composition is carefully prepared. An appropriate melting furnace is selected to fuse the alloy materials and produce a qualified liquid metal with correct composition and temperature.

Traditionally, smelting was carried out in a cupola furnace, but due to environmental concerns this method has been largely replaced by the use of electric furnaces.

5. Pouring stage

The molten metal produced in the electric furnace is transferred to the mold through a ladle.

It is important to control the pouring speed to ensure that the entire mold cavity is filled with molten metal.

Please note that spilling molten metal can be dangerous and appropriate safety precautions should always be taken.

6. Cleaning step

Once the molten metal solidifies after pouring, the gate is removed with a hammer and the sand is shaken out of the casting. The casting is then blasted with a sandblasting machine to obtain a clean surface.

Castings with less stringent requirements can usually be delivered after inspection.

7. Casting processing

Some castings with special requirements or that do not meet required specifications may require additional processing.

This is typically accomplished using a grinding wheel or grinder to remove any burrs and obtain a smoother surface on the casting.

8. Casting inspection

Inspections are usually carried out during the cleaning or processing phase and any unqualified castings are identified at this time.

However, some castings may have specific requirements and require additional inspection. For example, a casting may need to be tested by inserting a 2-inch shaft into its center hole to ensure it meets the required specifications.

Conclusion:

After completing the above 8 steps, the casting process is essentially complete. However, for castings that require high precision, additional machining may be required.

Please note that machining is outside the scope of this description.

As casting technology continues to advance, traditional sand casting is being improved or replaced by other methods.

Innovation is an eternal theme and a fundamental quality that a foundry must possess to be successful.

What equipment is needed for sand casting?

Sand casting is the most common and traditional casting method used in the foundry industry and is often the preferred choice for small foundry manufacturers in the beginning.

What are the basic equipment and tools required for the sand casting process?

The sand casting process requires the following equipment and tools according to the production process sequence: sand mixing equipment, mold making equipment, core making equipment, molding equipment, melting equipment, equipment casting equipment, cleaning equipment and casting processing equipment.

1. Sand mixing equipment

The equipment needed for this step is a sand mixer, and the tools needed are a shovel and a sieve.

Sand mold casting relies on sand, which serves as a special molding material.

Molding sand can be recycled, but must be sieved before reuse.

The sand should be fine and mixed evenly with a sand mixer.

A small sand mixer can cost as little as 2,000 units.

2. Mold making equipment

Required equipment: Engraving machine.

Required materials: Wooden mold, Plastic mold (special plastic plate), Metal mold (metal block).

The mold must be created based on the samples or drawings provided by the customer.

The quality of the mold directly impacts the accuracy of the mold shape.

Previously, wooden molds were typically made by carpenters. However, with the advancement of engraving machines, they are now used to create wood, plastic, and metal molds.

A basic engraving machine that can engrave wood and plastic molds can be purchased for a few thousand yuan. However, for metal engraving, you may need an engraving machine that costs tens of thousands to hundreds of thousands of yuan.

The price of the engraving machine is mainly determined by the material capabilities, accuracy and level of automation.

3. Core Manufacturing Equipment

Required equipment: Oven. Materials needed: Coated sand and thick gloves.

The process of creating internal cavities in castings usually involves making a core, and there are several methods for doing this.

The two most common methods are:

- First, the mold is made (usually together with the core mold in the first step) and then manually filled with a mixture of molding soil and sand (referred to as core beating).

- Secondly, the central aluminum box is filled with coated sand and fired in a kiln. The furnace can be a dedicated or self-made smelting furnace, which can be constructed by welding an iron sheet and baking it in the furnace.

Note that the center box becomes very hot during the burning process, so it is important to wear gloves for protection.

I recommend the second method as the coated sand baked core does not require burning during casting and results in a relatively clean internal surface of the casting.

4. Modeling equipment

Required equipment: Molding machines Required tools: sandbox, bottom plate, scraper, shovel, dipping pen, V-shaped iron sheet for gate opening, brush, air hole needle, etc.

Molding is the most demanding and crucial stage of sand casting, having the most distinctive industrial characteristics. In the past, molding was carried out entirely by hand, but today most molders use molding machines, significantly reducing labor intensity.

There are various tools used in molding, including sandbox for expansion, bottom plate, scraper, shovel, dip pen, V-shaped iron plate for opening the gate, brush, needle for air hole, among others. These tools are mostly small and customized by molders to suit their personal preferences.

In conclusion, producing a high quality mold is the key to success in this process.

5. Fusion equipment

Required Equipment: Electric Furnace and Transformers Required Materials: Iron, Aluminum, Copper and other Raw Materials, Tin and Iron (Lots).

The main purpose of this step is to melt the iron into cast iron. The challenge is mixing and controlling the temperature of the cast iron.

Due to the dome ban, most large and small factories now use electric furnaces as melting equipment. Electric ovens come in many sizes and have a wide price range. The smallest ones, with a capacity of 200 kg, cost between 10 thousand and 20 thousand, while the largest ones can cost hundreds of thousands to millions.

In addition to the electric oven, a special transformer is also required and must be purchased separately. Transformer use must be approved by the local energy agency and application costs vary.

Setting up a small foundry can cost at least several hundred thousand dollars, with half of the cost attributed to the application fee.

6. Pouring equipment

Required equipment: Cast iron ladle and overhead crane

The cast iron produced in the electric furnace can be divided into large and small quantities. It is first placed in a large container and then transferred to smaller containers for easier handling.

Workers carry the small containers and pour the molten iron into the completed mold. This stage involves high risks and workers must take the necessary protective measures.

In large factories, large castings are poured using large equipment such as overhead cranes. This helps ensure safety and efficiency in the casting process.

7. Cleaning equipment

Required equipment: Sand blasting machine

After the casting has cooled after the casting process, workers remove it from the mold. They remove most of the surface soil and break the gate with a hammer.

The next step is to place the casting in a sand blasting machine. This process helps to clean and smooth the surface of the casting.

8. Casting processing

Common Equipment: Grinding wheel, Polisher, Cutting Machine and Lathe.

Casting processing falls under the machining category. Most general machining equipment can be used, but it goes beyond the scope of casting.

Typically, foundries have the essential tools, such as grinding wheels, polishing machines, cutting machines, and it is advantageous to also have a lathe. These tools are sufficient for basic casting processing.

Summary

All work must be coordinated with each other. Small foundries that are just starting out may not have the full range of casting processes and may not have the ability to produce and process their own molds.

To compensate for this, they may collaborate with specialized mold makers and machinists and only be responsible for casting the blanks.

Casting is a traditional and admirable industry. Despite facing prohibitions due to environmental protection, many small traditional foundries have been engaged in casting their entire lives and have become unemployed or continued their work as professionals.

I would like to salute the older generation of foundry workers!