Everywhere in the industry and wherever moving parts operate, CV joints are likely to be required. Especially in the case of connecting stagnant and moving parts that need to remove deterioration by friction.

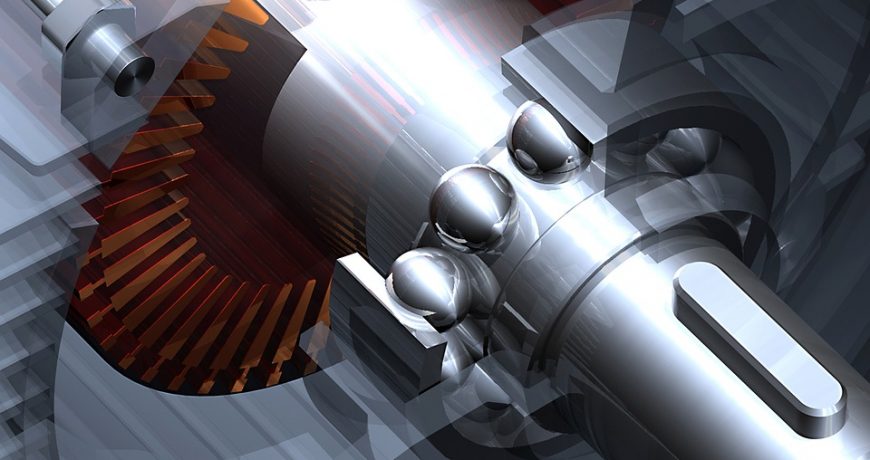

An Introduction to Ball Bearings

Ball bearings consist of a fixed body and a rotating shaft. Together, they are the solution to keeping the gears turning in many industrial contexts.

When purchasing ball bearings and other distribution locations around the world, it is important to understand what exactly a ball bearing is, how it works, and which types of bearings are suitable for your mechanisms.

There are five most common parts of the ball bearing family. They all work together to maintain stability and frictionless connection between two components.

1. The steel balls

Starting from the center of the ball bearing, the steel balls play the most important role in performing functionality. They represent the rolling element of the bearing.

2. The cage

The cage holds the balls in a uniform ring, keeping them at equally spaced intervals within the bearing. The cage can be produced in different shapes and is developed with low-friction materials to allow the balls to continue rolling freely.

3. The inner ring

The inner ring (also known as the inner ring) is a smaller part in which ball bearings sit on a radial shaft. In most industrial cases, it is the inner ring that rotates when connected to moving parts. The inner and outer races (see below) have the same bandwidth but varying ring diameters to accommodate ball insertion.

4. The outer ring

The outer ring (also known as the outer race) is the larger ring under which the balls move on a radial axis. Since the inner race typically exhibits movement, it is recognizable that the outer ring is the stagnant component. Both the outer ring and inner ring feature a groove of varying depth to allow the rolling elements to slide without deflection.

5. The shield

Finally, the shield is an optional component of the ball bearing. However, it is highly recommended to purchase ball bearings with the shield included. The reasoning behind this is due to the prospects of greater durability; the shield is a cover that hides the rolling element. They can be made of metal to prevent dust accumulation or plastic to increase water resistance. At the same time, these screens help retain oil and grease to reduce the need for maintenance as they are kept lubricated throughout their life cycle.

To move correctly, bearings require radial and axial clearance (internal clearance) of these five parts. This allows for thermal expansion during operation caused by remaining friction levels. This special allowance prevents bearing pinching, wear and seizure.

What types of bearings are available from a bearing supplier?

Bearings are not a single industrial component. Therefore, when looking for your bearing supplier, you need to find out which bearing suits your operation and machine.

-

Radial bearings are designed to resist forces perpendicular to the input.

-

Thrust bearings enclose balls between raceways while resisting axial forces.

-

Angular contact bearings are designed to accommodate perpendicular and axial loads.

- Roller bearings are used to reduce friction rates between moving parts and support a greater load capacity than ball bearings.

-

Linear bearings allow movement in one direction, such as forward and backward.

-

Self-aligning bearings allow the shaft to be tilted via double roller bearings during operation.

- Mounted bearings are used to support rotating parts or separate rotating parts with a fixed one.

What are the main functions of ball bearings in machines?

Since they were patented by Jules Suriray in 1869 (before he won the world's first bicycle race in Paris), ball bearings have become an invaluable component for most machines and mechanisms in use today.

They are one of the most used mechanical parts and have homes in both domestic and industrial environments, such as: automobiles, hydraulic presses, bicycles, motorcycles, drills, couplings, winding mechanisms, motors, turbines, office equipment, medical equipment and much more.

This is because they perform three main functions:

1. They create resistance without friction

Without considering the use of magnetic bearings (which are not a subtype of ball bearings), frictionless resistance will not exist. Although they are commonly called frictionless drag components, they actually have drag reduced by friction. Spheres, although they minimize friction between two spokes, still require friction to stabilize one or the other spoke. Allowing for this reduced frictional resistance also means decreasing temperature, wear rate, and chance of part failure.

2. They connect two independent machine parts

In a mechanism, there is always a need to connect parts with joints. Ball bearings act as joints to combine two mechanism components (sometimes with variable axles) in the case of a rotating component such as a bicycle fork and its wheel.

3. They carry loads in the mechanism

Each ball bearing can support a load respective to the outer ring track width. Therefore, spherical bearings with double roller capability can withstand heavier load and remain durable. Bearings have a static load capacity that is reflected in the axial sealing limits; some types of heavy-duty bearings can support a load of up to 50% of the static load.

Why are ball bearings so important in industrial operations and commercial activities?

With the development of factories, production machines and industrial operations, more varied applications are needed to reduce time, space and downtime.

With ball bearings having the ability to reduce items between parts, effectively combine moving and static components without manual operations, and withstand specific amounts of load, they can greatly reduce the likelihood of mechanical failure.

Industries such as the automotive trade purchase ball bearings and more to provide motors with reduced frictional resistance to prevent temperature rises and component overloads. The use of friction-reducing ball bearings improves the car's overall performance and efficiency while reducing CO2 emissions.