Fundamental Shear Operation

Cut:

A shear force is applied that will cut part of a sheet. The cut 'blank' becomes the workpiece. Shearing, also known as die cutting, is a process that cuts material without the formation of chips or the use of burning or melting. In strict technical terms, the “shearing” process involves the use of straight-cut blades, sheets or plates, however, rods can also be sheared. Shearing type operations include shearing, drilling, roll cutting, and shearing.

Shear: Definition

- When you apply a high-pressure tool through a metal plate and remove some of the metal, the process is called shearing. Shear machining devices include punch machines, which make small discs, and cutting machines, which produce washers and similar objects.

- CUTTING is a method of cutting a piece of material into smaller pieces using a shear knife to force the material past an opposing shear knife in a progression of.

- Shearing is widely used to split large, flat materials such as sheets, strips, and plates. Sheet, strip and plate cutting is broadly classified according to the type of blade (knife or cutter) used as straight or rotary.

- Straight knife cutting is used to square and cut flat material into the desired shape and size. It is generally used to produce square and rectangular shapes, although triangles and other straight shapes are also cut with straight knives.

Characteristics of the shearing process include:

- Its ability to make straight-line cuts in flat sheets

- Placing metal between the upper and lower shear blades

- Its trademark is the production of burred and slightly deformed metal edges

- Its ability to cut relatively short lengths of material at any time, as the cutting blades can be mounted at an angle to reduce the cutting force required.

The shearing process involves cutting sheet metal, as well as plates, bars and tubes of various cross-sections, into individual pieces by subjecting them to shear stresses, typically using a punch and die, similar to the action of a drill punch. paper. The punch and die can be any shape, such as circular or straight blades, similar to scissors.

Important variables in the shearing process are:

- The strength of the punch.

- The speed of the punch

- The condition of the sheet edge.

- The punch and die materials.

- Punch clearance.

- Lubrication.

Shear mechanism:

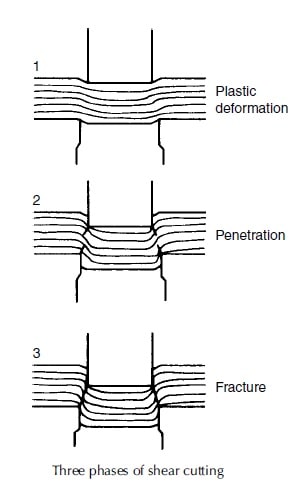

The cutting or punching action results from a closing movement of two sharp, closely adjacent edges in the material placed between them. The material is shear stressed to the point of fracture as it passes through three phases

1. Deformation:

As the cutting edges begin to close into the material, deformation occurs on both sides of the material near the cutting edge.

2. Penetration:

Cutting edges cut or penetrate the material, causing fracture lines.

3. Fracture:

The point where the upper and lower fracture lines meet. At this point the work is complete, but in punching, the punch must continue to move through the material to clear the mud.

phases of the shear mechanism

phases of the shear mechanismTypes of cutting machine

1. Cut with a straight knife

In straight knife cutting, the flat piece is placed between a stationary lower knife and a movable upper knife. As the upper knife is forced downward, it cuts the metal into two pieces. Straight knife cutting is the most economical method of cutting straight-sided blanks from flat sheets, strips, and plates no thicker than 50 mm (2 in.). The process is also widely used to cut the sheet into blanks that

will later be formed or drawn.

Straight knife cutting machines

Punch and press brakes may be used to cut some parts or are used temporarily when more efficient equipment is not available. Production shearing, however, is usually done on machines designed for this operation.

- Miter shears are generally used to trim and cut sheets, strips, or boards to a specific size (Fig.). These scissors (also called resquaring or guillotine scissors) are available in a wide variety of sizes and designs. Some line types also allow cutting when the part moves into the cut.

- The sheet, strip or plate is held firmly by clamping devices while the upper knife moves downward past the lower knife. The majority of the sheet or plate is cut by placing the upper knife at an angle (Fig. ).

- The position of one of the knives can be adjusted to maintain ideal clearance between the knives. Miter shears can be driven mechanically, hydraulically or pneumatically.

straight edge cutting machine

straight edge cutting machineMechanical Cutting Machine:

- The power train of a mechanical shear consists of a motor, the flywheel, a worm shaft that is driven by a gear driven by a flywheel, a clutch that connects the worm gear to the driven shaft, and a ram driven by the shaft. driven through eccentrics and connecting links.

- Under most operating conditions, a mechanical shear can deliver more strokes per minute (spm) than a hydraulic shear. Some mechanical scissors work as fast as 100 spams.

- Another advantage of mechanical shear is that, due to the energy stored in the flywheel, a smaller motor can be used for intermittent shear.

Hydraulic Cutting Machine:

- Hydraulic shears are driven by a motorized pump that forces oil into a cylinder against a piston; the movement of the piston energizes the ram that holds the upper knife.

- A hydraulic shear can make longer strokes than a mechanical shear. Hydraulic shears are designed with fixed load capacity.

Pneumatic Cutting Machine:

- Pneumatic shears are used almost exclusively to cut thin metal (rarely thicker than 1.50 mm or 0.060 in) into relatively short pieces (rarely longer than 1.5 m or 5 feet).

- Activation of the air cylinders causes the shear blade beam to move to make a cut. Compressed shop air or a stand-alone air compressor is used to supply power to the air cylinders.

Alligator Cutting Machine:

- Alligator shears have a cutting action similar to scissors. The lower knife is stationary and the upper knife, held securely by an arm, moves in an arc around a fulcrum pin.

- This type of machine is most widely used for cutting bars and bar profiles and for scrap preparation.

Rotary Cutting Machine

- Rotary cutting, or circular cutting (not to be confused with slitting), is a process for cutting sheets and plates in a straight line or contour using two rotating conical circular cutters.

- Cutting parts into circular parts requires the use of a fixture that allows the part to rotate to generate the desired circle. For straight line cutting on a rotary shear, a straight edge attachment is used, mounted in the throat of the machine, behind the cutting heads.

Working of hydraulic cutting machine:

hydraulic cutting machine

hydraulic cutting machineShear principle:

cutting principle

cutting principlewhere,

F = force required to shear

t = sheet thickness

w = sheet width

UTS = Ultimate shear strength of the material

Friction between the punch and the workpiece can, however, significantly increase the force of the punch. Furthermore, in addition to the force of the punch, a force is required to remove the punch from the sheet during its return stroke. This second force, which is in the opposite direction to the punch force, is difficult to estimate due to the many factors involved in the operation.

Cutting operations:

- The most common shearing operations are punching – where the cut piece is scrap or can be used for some other purpose – and blanking – where the piece is the part to be used and the rest is scrap.

- Shearing can also be done between a punch and a die, as shown in Fig. Shearing operations that use a die include punching, cutting, piercing, notching, cutting, and nibbling.

Drilling/Erasing

Punching or stamping is a process in which the punch removes a portion of material from a larger part or strip of sheet metal. If the small piece removed is discarded, the operation is called punching, while if the small piece removed is the useful part and the rest is scrap, the operation is called blanking.

Drilling:

It is a process by which a hole is cut (or ripped) in the metal. It's different from punching because piercing doesn't generate a bullet. Instead, the metal is pushed back to form an irregular flange at the back of the hole.

A punched hole looks like a bullet hole in a sheet of metal.

Cut:

When parts are produced by die casting or forging, a small amount of extra metal spills onto the parting plane. This extra metal, called burr, is cut off before the part is used, in an operation called trimming. The operation is very similar to cutting and the dies used are also similar to cutting dies. The presses used for trimming, however, have a relatively larger table.

Notch:

It is an operation in which a small specified amount of metal is cut from a blank. It is different from punching in the sense that in notching the cut line of the formed insert must touch an edge of the blank or strip. A notch can be made in any shape. The purpose of notching is generally to free metal for assembly.

Nibbling:

Nibbling is a variation of carving, with overlapping notches being cut into the metal. The operation can be used to produce any desired shape, for example flanges, collars, etc.

Drilling:

Drilling is an operation in which several evenly spaced holes are drilled in a sheet of metal. The holes can be any size or shape. They generally cover the entire sheet metal.

Cutting machine process parameter:

The main processing parameters in shear are

- The shape of the punch and death

- The speed of the punch

- Lubrication

- The clearance, c, between the punch and the die.

cutting operation process

cutting operation processThe clearance, c, between the punch and the die.

Gap is an important factor in determining the shape and quality of the cut edge. As the gap increases, the deformation zone (Fig. ) becomes larger and the cut edge becomes rougher. The sheet tends to be pulled into the gap region and the perimeter or edges of the shear zone become rougher. Unless such edges are acceptable as produced, secondary operations may be

necessary to make them smoother (which will increase production cost).

The speed of the punch

Edge quality can be improved by increasing drilling speed; speeds can be as high as 10 to 12 m/s. As shown in Fig., cut edges can undergo severe cold working due to the high shear deformations involved. Work hardening of the edges will then reduce the ductility of the edges and thus adversely affect the formability of the sheet during subsequent operations such as bending and stretching.