Laser Protection – Antifreeze Edition

As the seasons change, there is now a touch of winter in the air. With the climate becoming increasingly cold (especially in the north), when the ambient temperature begins to drop below 0°C, the equipment's water channels can freeze, causing damage.

This is a challenge for fiber lasers and laser equipment…

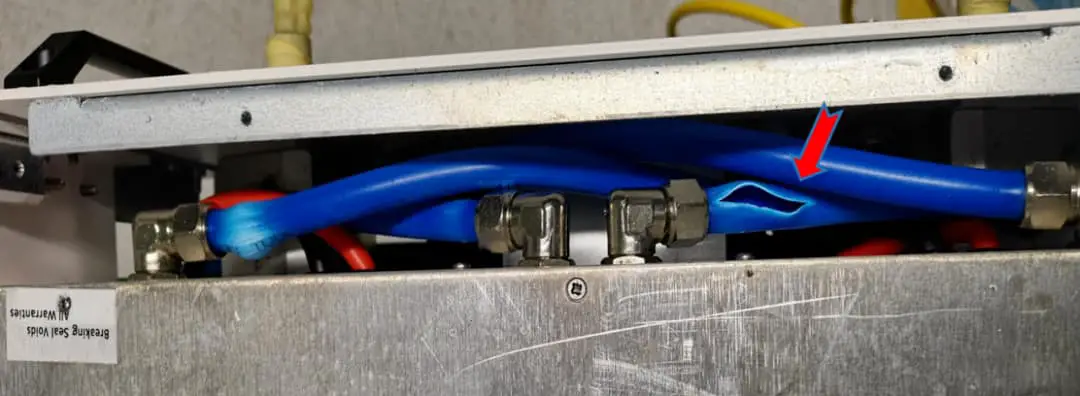

When the water inside the laser freezes and turns to ice, its volume expands, causing blockages in the tubing, cracks in the laser's internal water cooling plates, cracks in the fasteners and QBH crystals, and cracks in the water pipes and gaskets. laser waterway water pipes. .

This can cause damage or short circuits with water leakage, damage fiber lasers and other laser device components, and other problems. In serious cases, it can even render the laser irreparable, causing work stoppages and significant losses for customers. Below are some damages caused by not implementing anti-icing measures in time:

Laser freeze damage is significant and freeze damage is not covered by the laser warranty. It is clear how important it is to protect lasers and laser equipment from freezing in harsh winter weather.

There are three antifreeze measures for lasers: add antifreeze; drain the water inside the laser and output head; keep the water cooler running all the time (not recommended).

How to protect your laser?

Based on different practical situations and the principle of economic applicability, I will explain the following two operations in detail:

1. When the temperature drops below 0°C and the laser equipment is not used for a long time or needs to be transported, the water inside the laser and laser equipment needs to be drained to prevent freezing. See how:

1. Disconnect the water tube at the back of the laser and open the ball valve to let the water inside the laser flow.

2. Blow clean compressed air or nitrogen at 0.5 MPA (5 kg) into the main circuit water outlet. Blow for 3 minutes, pause for 1 minute and repeat 4 to 5 times, observing changes in the water mist at the drain outlet. The absence of water mist in the drain indicates that the draining step is complete. Finally, close the laser's ball valve and seal the water pipe connection with a plug or tape to prevent dust accumulation.

3. Remove the water inlet and outlet pipes Φ6 from the QBH outlet head of the machine tool.

4. Blow clean compressed air or nitrogen at 0.2 MPA (2 kg) into one Φ6 thin water pipe, with the other Φ6 thin water pipe facing down, until there is no water mist in the water pipe facing downwards. Then seal the water inlet and outlet pipes with tape. During this operation, take care to prevent water from dripping onto the laser head and other circuits.

2. When the temperature drops below 0°C and the laser device needs to be used normally, the temperature of the low-temperature water of the water chiller should be adjusted to 24-26°C, and that of the high-temperature water should be set to 26-28°C.

Add antifreeze to the cooling water in different proportions. We recommend using standard American Koolance antifreeze; Poor quality or inferior antifreeze will not only fail to serve its purpose, but will also corrode the laser's internal water pipes.

The proportion of adding antifreeze can be consulted in the following table, and the specific proportion can be adjusted according to the actual conditions.

| Antifreeze mixture ratio (antifreeze: cooling water) | Operating ambient temperature |

| 2:8 | -2~5°C |

| 3:7 | -12~15°C |

| 4:6 | -22~25°C |

| 5:5 | -32~35°C |

| 6:4 | -42~45°C |

| Clariant antifreeze ratio | |

| Local temperature -42 ℃~-45 ℃ | 6:4 (60% antifreeze, 40% deionized water) |

| Local temperature -32 ℃~-35 ℃ | 1:1 (50% antifreeze, 50% deionized water) |

| Local temperature -22 ℃~-25 ℃ | 4:6 (40% antifreeze, 60% deionized water) |

| Local temperature -12 ℃~-15 ℃ | 3:7 (30% antifreeze, 70% deionized water) |

| Shell OAT-45℃ antifreeze ratio | ||

| Ambient temperature (℃) | Shell OAT-45 ℃ (liters) | Deionized water (liters) |

| -5 | 0.5 | 1 |

| -10 | 0.8 | 1 |

| -15 | 1 | 1 |

| -20 | 1.5 | 1 |

| -25 | 2.2 | 1 |

| -30 | 4.1 | 1 |

| -35 | 5.8 | 1 |

| -40 | 1 | 0 |

| -45 | 1 | 0 |

The operation to add antifreeze is as follows:

1. Turn off the water cooler, disconnect the power supply and open the drain valve to empty the water.

2. Pour antifreeze and clean cooling water into the same container according to the proportion in the reference table.

3. Shake the two solutions in the container evenly. Mix the antifreeze in another container before pouring it into the water cooler. Do not add antifreeze directly to the water cooler.

4. Add the mixed solution to the water tank of the water cooler, turn it on and let the water circulate until the fluid level reaches the required level.

Observation:

- The antifreeze replacement cycle is 90 days. In spring, when there is no risk of freezing, replace the antifreeze with plain water; do not reuse antifreeze.

- No antifreeze can fully replace deionized water; therefore, prolonged use is not recommended.

- After winter, when the climate warms up and the temperature remains stable above 0°C, it is advisable to clean the system with deionized or distilled water and use it again as a refrigerant.

Common questions

1. Antifreeze measures

- Operate normally during the day and maintain power at night without turning it off, regulating the water cooler temperature above 0°C;

- As much as possible, keep the laser's working environment within the temperature range of 25±3°C to ensure that the laser is always operating in the ideal environment;

- Add antifreeze in a timely manner to prevent the water cooling pipes from freezing and bursting, which may cause coolant leaks. If the temperature drops below 0°C, replace all cooling water with antifreeze;

- Store the laser and other equipment at a temperature preferably above 5°C;

- If it is not used for a long period of time or in the event of a power outage, drain the water from the water cooler and store the equipment in an environment above 5°C.

2. Water chiller drain method

Step 1: Turn off all power sources before draining, open the drain valve behind the water cooler and empty the accumulated water;

Step 2: Remove the water inlet and outlet pipes behind the chiller and label them for accurate reinstallation;

Step 3: Unscrew the chiller filter element to drain the water inside;

Step 4: Connect 0.2 MPA (2KG) of compressed air to one end of the water pipe to drain the water accumulated in the laser.

Observation

If using an air gun to blow out the water, open all doors (including the water addition port) in advance. Blow air through the water inlet, not the outlet, and make sure the air pressure is not too high to avoid damaging the laser. Make sure all water is completely drained to prevent any residual liquid from freezing and damaging the cooling tubes and components.

3. Precautions when using antifreeze

- Antifreeze should not be used for long periods as it has an expiration date and can deteriorate. When the weather warms up, be sure to drain it, clean the pipes, and switch back to deionized water;

- Do not mix different brands or types of antifreeze, as their chemical components are different and can react and lose the effectiveness of the antifreeze, in addition to leaving contaminating residues;

- For antifreeze brand and ratio, we recommend Clariant brand Antifrogen-N ethylene glycol water-based antifreeze.

See suggested mixing ratios for antifreeze use.

4. Winter Boot Precautions

- Make sure the internal temperature is between 5-35°C before turning on the laser equipment;

- Check the water cooling pipes for ice. Do not turn on the laser equipment if ice is forming;

- In case of ice formation, turn on the heating or air conditioning to adjust the ambient temperature of the laser equipment to 5-35°C and let it sit for more than 4 hours until the ice melts naturally. Do not remove the ice by force to avoid damaging the hardware;

- Once confirmed that there is no ice formation on the laser equipment, turn on the water chiller for preheating;

- After the circulation temperature of the water cooler returns to normal (recommended temperature: about 25±3°C), you can turn on the laser;

- After normal startup, adjust the power below 30%, perform no-load preheating for about 10 minutes, and then proceed with regular production operations.