Laser cutting machine is an efficient and high-precision cutting device widely used in the metallurgical industry. It mainly consists of the following main components:

Fiber laser: The fiber laser is the heart of the laser cutting machine and one of the most expensive components. It directly affects the performance of the cutting device and the entire cutting process. Popular brands of fiber lasers on the market include IPG from Germany, SPI from Britain and Raycus from China.

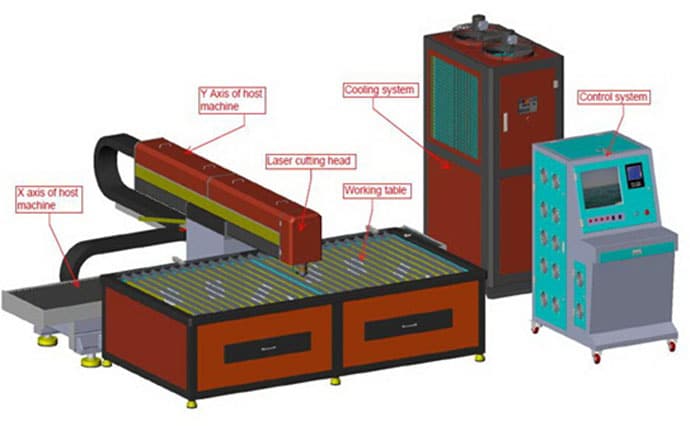

Machine tool main body: This includes the cutting work platform used to place the workpiece to be cut and can move accurately according to the control program. The machine tool part carries out the movement of the X, Y and Z axes and forms the basis for the cutting operation.

Beam transmission components: This includes beam expanders, protective lenses, and others. These components can change the diameter and divergence angle of the laser beam, while also protecting the lens from damage from splashing debris.

Cooling system: The laser cutting process generates a significant amount of heat, hence the need for a cooling system to maintain normal operation and extend the life of the equipment. The cooling system typically includes a circulating water cooling system and an air cooling system.

Gas supply system: This provides auxiliary gases for the cutting process, such as oxygen and nitrogen. These gases serve to cool and clean the cutting area, improving the quality and efficiency of the cut.

Laser cutting head: This includes the cavity, focusing lens holder, focusing lens and other components. The driving device is used to move the cutting head along the Z axis direction according to the program, achieving accurate cutting of the material.

Microcomputer numerical control cabinet: This controls the entire operation process of the cutting device. All operational commands of the fiber laser cutting machine are issued here.

In conclusion, the main components of the laser cutting machine include the fiber laser, the main body of the machine tool, the beam transmission components, the cooling system, the gas supply system, the laser cutting head and the microcomputer numerical control cabinet. These components work together, ensuring efficient and precise cutting capabilities of the laser cutting machine.

Auxiliary equipment for laser cutters includes:

- stabilizer power supply

- water chiller

- gas cylinder

- air compressor

- gas storage tank

- cooling dryer

- filter

- air filter

- slag discharge machine

Let's dive into this and I will divide the laser cutter into 14 parts and explain each of them in detail.

Laser Cutting Machine Components

1. Laser Cutter Frame

The mechanical part of the laser cutter is responsible for movement in the X, Y and Z axes, including the cutting work platform. Machine tool stability is crucial for fiber laser cutting machines as it directly impacts cutting accuracy.

Currently, the most common machine tools on the market are gantry type, cantilever type and beam type.

Each type of machine tool has its own functions, such as beam-type machine tools, mainly used by large manufacturers for cutting materials, and 3D fiber laser cutting, mainly used in the automotive industry.

2. Laser generator

A device that produces a source of laser light is known as a laser generator. The laser generator is the main power source of laser equipment, similar to a car engine, and is the most expensive component of fiber laser cutting machines.

Currently, the brands of imported fiber laser generators on the market include German IPG, ROFIN and British SPI, among others.

With the advancement of technology, national laser brands have also emerged, such as Raycus and Max, gaining recognition in the market for their high cost-performance ratio.

3. Lenses

The laser lens is the most commonly used component in fiber laser cutting equipment. Various optical devices contain laser lenses, each serving a different purpose, such as total reflection lenses, semi-reflection lenses, and focusing lenses.

Lens quality directly impacts the laser output power, thus affecting the overall performance of the machine. Although imported lenses have longer service life and better cutting effect compared with domestic lenses, they are much more expensive.

4. CNC System

The control system is the main operating system of the fiber laser cutting machine, which mainly controls the movements of the X, Y and Z axes and regulates the laser output power. Its quality determines the stability of the machine's operational performance.

Cutting accuracy and effect can be effectively improved through precise software control.

5. Regulated power supply

The connection between the laser generator, the laser cutter and the power supply system is mainly to prevent interference from the external power supply network.

6. Laser cutting head

The cutting head is the laser output device of a fiber laser cutting machine, consisting of a nozzle, a focusing lens and a focus tracking system.

The cutting head driving device, which consists of a servo motor, screw rod or gear, moves the cutting head along the Z axis as programmed.

However, the height of the laser cutting head must be adjusted and controlled depending on the material, thickness and cutting method used.

7. Control platform

The control process of the entire cutting device.

8. Engine

The laser cutting machine motor is a crucial component of the motion system. Engine performance directly impacts processing quality and product production efficiency.

At present, the commonly used motors are stepper motor and servo motor, which are selected based on the requirements of the industry and the processing object.

Stepping Motor: It has a fast startup speed, responsive and is suitable for engraving and cutting processing. They are affordable, with many brands offering different performance options.

Servo motor: It features fast moving speed, smooth operation, high load capacity and stable performance. It is ideal for industries and products with high processing requirements, providing smooth edge processing and high cutting speed, although it is more expensive.

9. Water cooler

The cooling system is used to cool the laser generator of a fiber laser cutting machine. The laser generator converts electrical energy into light energy, with a conversion rate of 20% in the case of a CO2 laser. The remaining energy is converted into heat.

The cooling water system removes excess heat to keep the laser generator working properly.

The cooler also cools the outer optical path reflector and focusing mirror to ensure stable beam transmission quality and prevent lens deformation or cracking due to overheating.

10. Gas cylinders

The working medium and auxiliary gas cylinders of the laser cutter are included.

These gases serve as industrial complements for laser oscillation and as auxiliary gases for the operation of the cutting head.

11. Air compressor, gas storage tank

Supply and store compressed air.

12. Air Cooling Dryer, Filter

The air supply system is used to supply clean and dry air to the laser generator and laser beam path, ensuring the normal operation of the path and reflectors.

13. Dust extractor

Smoke and dust generated during the manufacturing process must be filtered and treated to meet environmental protection standards.

14. Slag Discharge Machine

Eliminate leftover materials and waste generated during processing.

What types of cooling systems are there for laser cutting machines and what are their respective advantages and disadvantages?

Laser cutting machines mainly employ two types of cooling systems: water circulation cooling system and coolant circulation cooling system.

Water circulation cooling system:

The operating principle of this system involves throttling and depressurizing the refrigerant liquid through a capillary tube, flowing to the evaporator. Here, it vaporizes, absorbing heat from the cooled water from the external water circulation cooling system, turning into high-temperature refrigerant vapor that is sucked into the compressor. Once inside the compressor, it is compressed into high-temperature, high-pressure steam for discharge. However, it can have disadvantages, such as the need for regular maintenance to prevent blockages or leaks in pipes, and in some cases, water quality issues can affect the long-term operation of the equipment.

Refrigerant circulation cooling system:

This system, similar to the water circulation refrigeration system, achieves refrigeration effects through the circulation of the refrigerant. Its advantage lies in providing more precise and stable cooling effects, especially when it comes to high power density laser systems. However, this system typically has a higher cost and may require professional technical support for maintenance and troubleshooting.

Choosing the correct cooling system is crucial to ensure the normal operation of the laser cutting machine and extend its service life. The water circulation refrigeration system, due to its lower cost and ease of maintenance, is widely used, while the refrigerant circulation refrigeration system, with its efficient and precise refrigeration capacity, is suitable for applications with higher power requirements. refrigeration. Users should choose the most suitable type of refrigeration system based on their specific needs and budget.

How can we optimize the gas supply system of a laser cutting machine to improve cutting efficiency and quality?

To optimize the gas supply system of a laser cutting machine for greater efficiency and cutting quality, consider the following aspects:

Choose the appropriate auxiliary gas: Select the most suitable auxiliary gas based on different materials and cutting requirements. For example, nitrogen is mainly used as a significant auxiliary gas in the laser cutting industry. The carbon dioxide laser is one of the most commonly used gas lasers for laser cutting.

Maintain auxiliary gas consistency: The laser machine requires consistent auxiliary gas pressure and flow to maintain cut quality. Failures in the gas supply can lead to unnecessary pressure drops, affecting production quality.

Optimize the gas supply pipeline: The length and diameter of the gas pipeline determine the flow of auxiliary gas. Ideally, the supply piping should have minimal curvature to reduce resistance to gas flow, ensuring stability and sufficiency of the gas supply.

Adjust the distance between the nozzle and the material: By adjusting the distance between the nozzle and the material, you can effectively improve the cutting efficiency of the equipment.

Increase power: Properly increasing laser power can improve cutting speed and quality while ensuring safety.

Establish a good working environment: A favorable working environment temperature is equally important to the efficiency and cutting quality of the laser cutting machine.

Use a professional nitrogen generator: By optimizing a professional nitrogen generator for PSA laser cutting, you can supply high-quality nitrogen to the laser cutting process, thereby improving cutting efficiency and quality.

What is the role of microcomputer numerical control cabinet in laser cutting machines and its impact on machining accuracy?

The microcomputer numerical control cabinet plays a key role in laser cutting machines. It forms the core of the laser cutting system together with the laser generator, beam transmission components, workbench (machine tool), cooler and computer.

The main function of the microcomputer numerical control cabinet is to control the precise movement and cutting process of the laser through computer programming, ensuring that the laser operates accurately on the workpiece along a predetermined path.

The microcomputer numerical control cabinet greatly influences the machining accuracy.

Firstly, it ensures high precision and quality during the laser cutting process by precisely controlling the output power and moving speed of the laser.

Secondly, the microcomputer numerical control cabinet adjusts cutting parameters such as focal point location and gas pressure according to different types of materials and thicknesses to meet diverse cutting needs, further increasing machining precision.

Furthermore, it supports complex cutting path planning, enabling the laser cutting machine to perform efficient and precise cutting on complex shaped parts, significantly improving processing efficiency and yield rate.

The microcomputer numerical control cabinet is not only a key component in laser cutting machines, but also plays a decisive role in ensuring machining accuracy, increasing production efficiency and improving product quality.