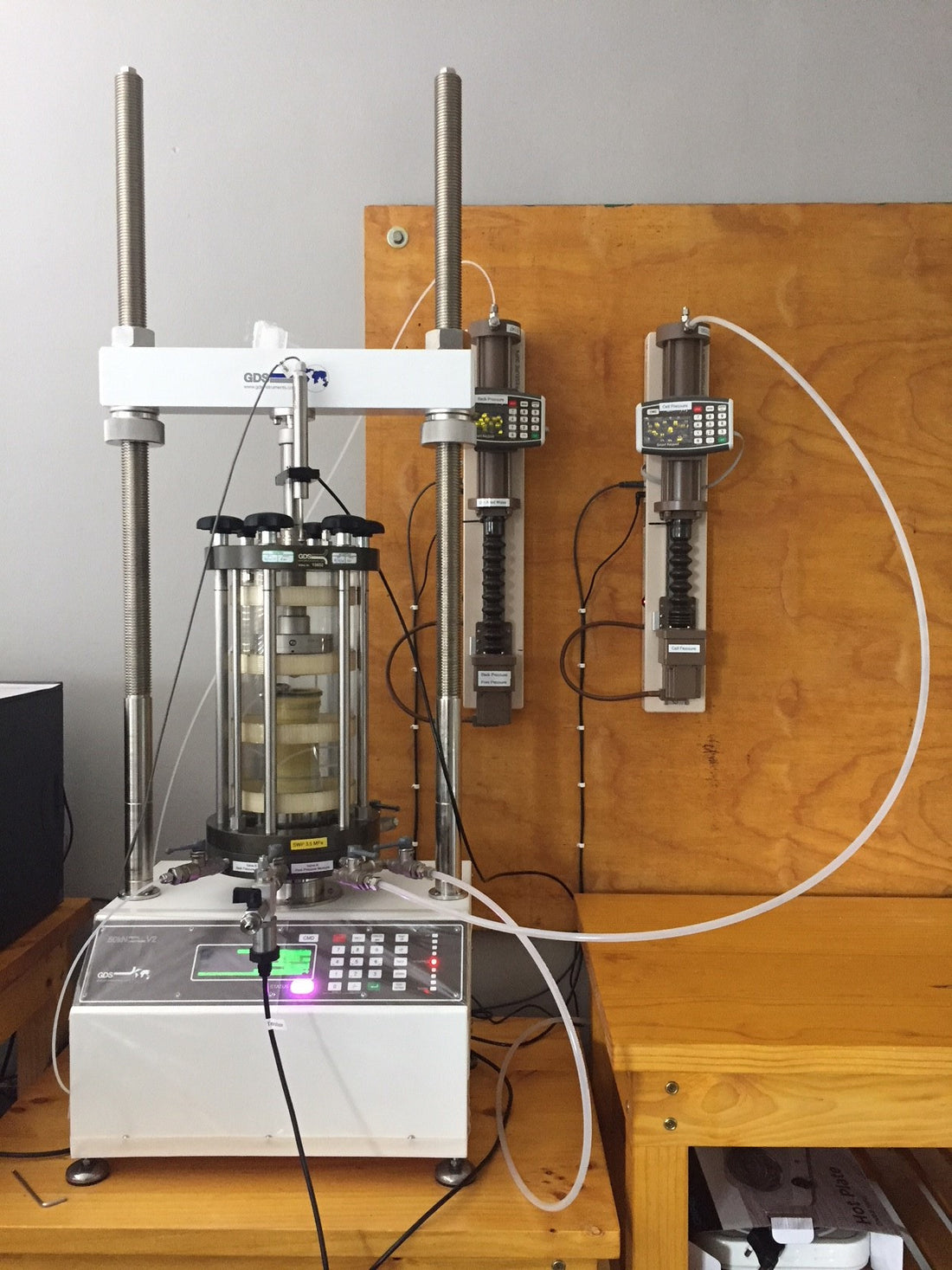

Civil engineering and geotechnical engineering are important branches of engineering involved in the construction and maintenance of safe infrastructure. Triaxial testing is a powerful tool that allows civil and geotechnical engineers to obtain information about the strength and other soil and rock properties of a given material. In this post, I discuss the basics of triaxial testing, its advantages, and important considerations when planning such testing. This article is certainly a useful guide for civil engineers and geotechnical engineers who want to better understand the performance of triaxial tests in their work.

Triaxial tests are performed by carrying a cylindrical sample of soil or rock in three perpendicular directions. The measured response of the sample to this load provides engineers with valuable information about the strength and other properties of the material. Because triaxial tests are performed on a small, controlled sample of material, they are an effective method for gaining insight into the behavior of larger, real-world structures.

From the triaxial test data, the basic material properties of the sample can be determined, such as the shear strength angle, apparent cohesion, and expansion angle. To predict how the material would behave in a larger engineering application, these parameters are then used in computational models.

The triaxial test can be used to determine the geotechnical parameters of the soil.

- Cohesion (c) of the soil

- Angle of internal friction ( φ ')

- Soil shear strength

- Soil rigidity

- Soil permeability

There are many advantages to using triaxial testing in engineering. First, they are relatively easy and quick to perform. Secondly, they provide reliable and repeatable results. And third, they can be used to test a wide range of materials, from soft soils to hard rocks.

There are also some important aspects to consider when planning a triaxial test. First, it is important to select an appropriate sample size. Second, the experiment must be designed to accurately simulate the stress conditions encountered in the field. And third, care must be taken to ensure that the experiment is carried out under conditions that minimize the risk of sample failure.

Overall, triaxial testing is a powerful tool that can provide valuable information about the strength and behavior of soil and rock materials. When planning a triaxial test, it is important to select an appropriate sample size, design the test to accurately simulate the loading conditions encountered in the field, and ensure that the test is conducted under conditions that reduce the risk of sample failure.

Although triaxial tests are most commonly used to measure the strength of materials, they can also be used to measure other properties such as compressibility, deformation, and shear strength of soils.

Types of Triaxial Tests

Triaxial tests are used to measure the strength and deformation properties of earth, rock, and other materials. There are different types of triaxial tests, each designed to test different aspects of a material's properties. These tests are used in various areas, such as geotechnical engineering and construction, to analyze soils and other materials and ensure their structural integrity.

- Unconsolidated – undrained (UU)

- Consolidated – undrained (CU)

- Consolidated – drained (CD)

Unbound – undrained triaxial test

Soil mechanical properties are determined by subjecting a soil sample to various stress and drainage conditions in a triaxial, unconsolidated, drained compression test. In a triaxial cell, pressure from a confining fluid is applied to the saturated sample. Typically, the test uses three samples of the same soil sample subjected to different limiting stresses.

Testing is performed in accordance with ASTM D2850-15.

The strength resulting from measuring a soil's compressive strength against total stress using this test method depends on the pressure created in the pore fluid during loading. This testing method prevents fluid from leaking out of or into the soil sample when tension is applied. Therefore, pore pressure and resulting resistance are different from those created in situations where drainage is possible.

Shear strength for an unconsolidated, undrained structure is applicable when the speed of load movement is so high that there is not enough time for consolidation to occur during the loading period or the resulting pore water pressure can be reduced.

Consolidated – undrained triaxial test

The shear strength of the soil is determined using a three-axis consolidated undrained compression test. Before failure due to increased primary principal stress is detected, the soil pore pressure is recorded and the soil is compacted in a triaxial cell under pressure from all sides.

The triaxial shear test can evaluate the total and effective stress of the soil and determine the shear strength of the soil, including cohesion and angle of internal friction.

Consolidated – dehydrated triaxial test

The consolidated drained triaxial compression test is performed in the same manner as the consolidated undrained test, except that during shearing the back pressure is still associated with the sample, which is gradually loaded sufficiently to prevent the development of excessive pore pressures.

Advantages of triaxial testing

- We can control drainage conditions

- Therefore, it is easy to perform the three types of tests UU, CU and CD without much trouble

- More accurate results can be obtained from the test

- Uniform distribution of shear strength on the fracture surface

- From the experiment, the variation in soil stresses can be determined and the behavior of the soil can be further investigated.

Disadvantages of triaxial testing

- Due to the high level of equipment required, the test is comparatively expensive.

- There are other comparatively simple methods with which these parameters can be determined.