The cost of developing and managing a building is high, especially in places like New York City. However, there are many ways homeowners can avoid spending more than necessary. Design decisions have an impact throughout the entire life cycle of the building, and costs can be optimized with well-planned maintenance and eventual building upgrades.

Residential and commercial developers can become more competitive by reducing the total cost of ownership of buildings. This increases profit margins and part of the savings can be passed on to tenants by offering lower rental rates than competitors.

This article describes some common mistakes that increase the cost of ownership of buildings without offering anything in return to project owners.

Optimize your construction costs and achieve long-term savings.

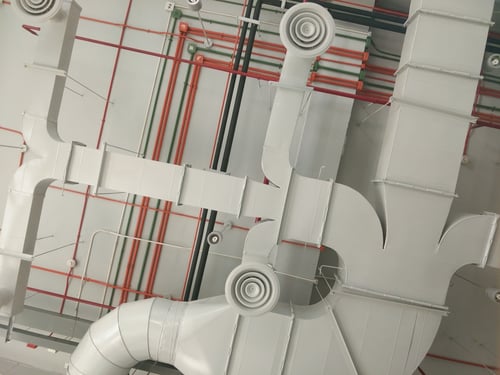

Oversized MEP installations

For building developers, the “more is better” mentality applies to profit margins, occupancy rates and return on investment. However, this does not apply to the capacity of construction systems; for example, a 300-ton cooling plant offers no benefit if the maximum cooling load is 200 tons.

- Large equipment has a higher price and a higher operating cost.

- Maintenance is more demanding when building installations are oversized and parts replacements are more expensive.

- In some cases, building performance is compromised by oversized equipment. For example, an HVAC system that produces excessive heating or cooling causes occupant discomfort and possibly health problems.

- Oversized equipment operates at partial load and many types of equipment suffer a drop in efficiency.

Best performance is achieved when building systems are optimally sized and an MEP engineering firm can select the most appropriate equipment capabilities. Oversizing is common when MEP installations are sized based on “rules of thumb” rather than a detailed analysis of building requirements.

Change orders during construction

Many projects become more expensive due to changes during their construction process. This often occurs when the project scope is not clearly defined or when conflicting equipment locations are specified for different building systems. There are many ways to minimize change orders or avoid them altogether:

- Arrange an initial meeting with equipment suppliers and contractors to ensure there are no conflicting specifications in the design documents.

- Work with a single MEP engineering firm rather than having separate design teams for mechanical, electrical, and plumbing systems. When design teams are separated, they have no way of knowing whether the proposed layout conflicts with another construction system.

- 3D modeling tools like Revit are very useful as they can detect conflicting specifications immediately.

Design changes are much simpler and faster than changes to the work completed during the construction phase. Also consider that design changes only require hours of work from the engineering team, while changes during construction waste materials and labor.

Do not update build systems

Buildings last for many decades, which means MEP systems eventually become obsolete as new technologies come onto the market. Developers should conduct property assessments at regular intervals to find opportunities for improvement. For example, fluorescent lighting was a great building upgrade when it was a new technology, and now LED lighting is the most economical option.

Construction systems wear out with use, gradually increasing the consumption of electricity, gas and water. Furthermore, these services tend to increase in cost over time. An effective solution is to upgrade the MEP system when emerging technologies come to market at a competitive price.

Not having a preventative maintenance program

Preventative maintenance is much more effective than fixing problems as soon as they occur. When a maintenance team follows a reactive approach, problems become more expensive to resolve and more disruptive to the building. Major equipment failures can also damage other components, leading to repairs that would not be necessary with preventive maintenance.

Also consider that preventive maintenance can be scheduled, while emergency repairs cannot. This means that parts can be purchased in advance with a preventive maintenance program, while emergency repairs require emergency purchases and component availability is not guaranteed.

Conclusion

Construction ownership costs can be reduced in several ways. Professional design services, effective project management, frequent property assessments, and a preventive maintenance program can save you thousands of dollars each year. Although these services require qualified labor, their cost represents only a small fraction of the savings achieved – they can be considered a profitable investment.