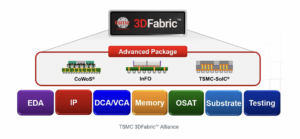

TSMC recently announced the 3DFabric Open Innovation Platform (OIP) Alliance at the 2022 Open Innovation Platform Ecosystem Forum. The new TSMC 3DFabric Alliance is TSMC's sixth OIP alliance and the first of its kind in the semiconductor industry uniting forces with partners to accelerate innovation and readiness of the 3D IC ecosystem – with a full range of best-in-class solutions and services for semiconductor design, memory modules, substrate technology, testing, manufacturing and packaging.

This alliance will help customers achieve rapid implementation of silicon and system-level innovations and enable next-generation HPC and mobile applications using TSMC's 3DFabric technologies, a comprehensive family of 3D silicon stacking and advanced packaging technologies.

This alliance will help customers achieve rapid implementation of silicon and system-level innovations and enable next-generation HPC and mobile applications using TSMC's 3DFabric technologies, a comprehensive family of 3D silicon stacking and advanced packaging technologies.

“3D silicon stacking and advanced packaging technologies open the door to a new era of chip- and system-level innovation, and also require broad ecosystem collaboration to help designers navigate the best path through the myriad options and approaches available to them,” said Dr. LC Lu, TSMC Fellow and Vice President of Design and Technology Platform. “Through the collective leadership of TSMC and our ecosystem partners, our 3DFabric Alliance offers customers an easy and flexible way to unleash the power of 3D IC in their designs, and we can't wait to see the innovations they can create with our 3DFabric technologies.”

“As a pioneer in 3D silicon chips and stacking, AMD is excited about the introduction of TSMC’s 3DFabric Alliance and the vital role it will play in accelerating system-level innovation,” added the senior vice president of technology and AMD product engineering, Mark Fuselier. “We have already seen the benefits of working with TSMC and its OIP partners on the first TSMC-SoIC-based CPUs  in the world and we look forward to collaborating even more closely to drive the development of a robust chip stack ecosystem for future generations of high-performance, energy-efficient chips.”

in the world and we look forward to collaborating even more closely to drive the development of a robust chip stack ecosystem for future generations of high-performance, energy-efficient chips.”

OIP 3DFabric Alliance

As the industry's most comprehensive and vibrant ecosystem, TSMC OIP consists of six alliances: EDA Alliance, IP Alliance, Design Center Alliance (DCA), Value Chain Alliance (VCA), Cloud Alliance and now the 3DFabric Alliance.

TSMC launched OIP in 2008 to help customers overcome the increasing challenges of semiconductor design complexity by creating a new paradigm of collaboration, organization of development and optimization of TSMC technologies, electronic design automation (EDA), IP and project methodology.

Partners in the new 3DFabric Alliance have early access to TSMC's 3DFabric technologies, allowing them to develop and optimize their solutions in parallel with TSMC. This gives customers a head start in developing their products with early availability of the highest quality, readily available solutions and services, from EDA and IP to DCA/VCA, memory, OSAT ( Outsourced Semiconductor Assembly and Testing), substrate and tests.

“The Amazon Annapurna Labs team is responsible for creating silicon innovation for Amazon Web Services customers, and we have collaborated closely with TSMC as we develop our AWS Trainium product using TSMC's advanced packaging technologies, including CoWoS and its infrastructure support from architecture definition, package design, and process validation to successful production,” said Nafea Bshara, Vice President and Distinguished Engineer, Amazon Web Services. “As a TSMC customer, we are pleased with the introduction of TSMC's 3DFabric Alliance OIP, which demonstrates TSMC's leadership and commitment to enabling next-generation 3D IC design.”

New collaboration with 3DFabric Alliance Partners

- EDA partners have early access to TSMC 3DFabric technologies for developing and enhancing EDA tools to deliver optimized EDA tools and design flows to enable 3D IC designs more efficiently.

- PI partners develop 3D IC IPs compatible with die-to-die interface standards and TSMC 3DFabric technologies to provide a wide range of the highest quality, proven IP solutions for customers.

- DCA/VCA partners gain early collaboration with mutual customers on 3DFabric technologies and roadmap alignment with TSMC that will improve their service capability for 3DFabric design, IP integration and production.

- Memory partners have early technology engagement to define specifications and early alignment on technical and engineering criteria with TSMC that will reduce time to market for future HBM generations to meet 3D IC design requirements.

- OSAT partners supporting TSMC's production quality and technical requirements collaborate with TSMC to meet customers' production demands with continuous improvements in all aspects of technology and production enablement and support.

- Substrate partners have early technology engagement and development with TSMC to meet future requirements for 3DFabric technologies that will improve substrate material quality, reliability and integration of new substrates to accelerate production of customers' 3D IC designs.

- Test partners collaborate early with TSMC to develop testing and stress methodologies for TSMC's 3DFabric technologies, providing comprehensive coverage of reliability and quality requirements to help customers quickly launch their differentiated products.

“NVIDIA manufactures with TSMC's CoWoS technologies and supports the infrastructure for multiple generations of high-performance GPU products,” said Joe Greco, senior vice president , advanced technology group, NVIDIA. “TSMC’s new 3DFabric Alliance will extend the technology to a broader set of products and an enhanced level of integration.”

TSMC3Dblox

To address the growing complexity of 3D IC design, TSMC introduced the TSMC 3Dblox standard to unify the design ecosystem with EDA tools and flows qualified for TSMC 3DFabric technology. The TSMC 3Dblox modularized standard is designed to model, in one format, the main physical stack and logical connectivity information in 3D IC designs.

TSMC worked with EDA partners in the 3DFabric alliance to enable 3Dblox for all aspects of 3D IC designs, including physical implementation, timing verification, physical verification, electromigration IR dropout (EMIR) analysis, thermal analysis, and more . TSMC 3Dblox is designed to maximize flexibility and ease of use, offering maximum productivity in 3D IC designs.

TSMC 3DFabric Technologies

TSMC 3DFabric, a comprehensive family of 3D silicon stacking and advanced packaging technologies, further expands the company's advanced semiconductor technology offerings to unlock system-level innovations. TSMC's 3DFabric consists of front-end, 3D chip stack or TSMC-SoIC (System on Integrated Chips) and back-end technologies that include the CoWoS and InFO family of packaging technologies, enabling improved performance, power, form factor and functionality to realize the system. level integrations.

In addition to CoWoS and InFO which are in volume production, TSMC has also started TSMC-SoIC silicon stack manufacturing in 2022. TSMC now has the world's first fully automated factory for 3DFabric in Chunan, Taiwan, which integrates advanced testing , TSMC-SoIC and InFO Operations together, offering the best flexibility for customers to optimize their packaging, leveraging better cycle time and quality control.