In electrical insulation diagnosis, the tan delta test is an important tool for evaluating the condition and integrity of high voltage devices. This advanced technology allows engineers and technicians to gain valuable information about the condition of electrical insulation, preventing costly failures and ensuring the safety and reliability of electrical systems. In this article, we delve into the world of Tan Delta testing and examine its purpose, principles, methods, predictive capabilities, and different modes.

What is the Tan Delta test?

Tan delta testing, also known as dielectric loss factor or power factor testing, is a sophisticated diagnostic method for evaluating the quality of insulation in high voltage equipment. Measures dielectric losses in the insulating material and provides important information about its condition. By analyzing the Tan Delta value, engineers can assess insulation integrity, identify potential failures, and make informed maintenance decisions.

Purpose of the Tan Delta Test

The main purpose of the Tan Delta test is to evaluate the insulation condition in high voltage devices such as transformers, cables and bushings. This test can achieve the following objectives:

Insulation deterioration detection

The Tan Delta test can detect even small defects or damage to insulation. This way, unexpected failures and downtime can be avoided.

Predict future failures

By monitoring changes in tan delta values over time, maintenance teams can predict when insulation is likely to fail, enabling proactive maintenance and replacement.

Ensuring security and reliability

Ensuring the integrity of electrical insulation is fundamental to the safety and reliability of power systems and minimizes the risk of electrical failures and accidents.

Tan Delta Test Principle

The Tan Delta test measures the phase difference between voltage and current in an insulating material. When high AC voltage is applied to insulation, some energy is lost due to dielectric losses in the material. This loss is represented by the tan delta value, which indicates the relationship between the power loss and the stored energy. A lower Tan Delta value indicates healthier insulation, while a higher value indicates possible problems or deterioration.

Tan Delta Test Method

Performing a tan delta test involves several important steps:

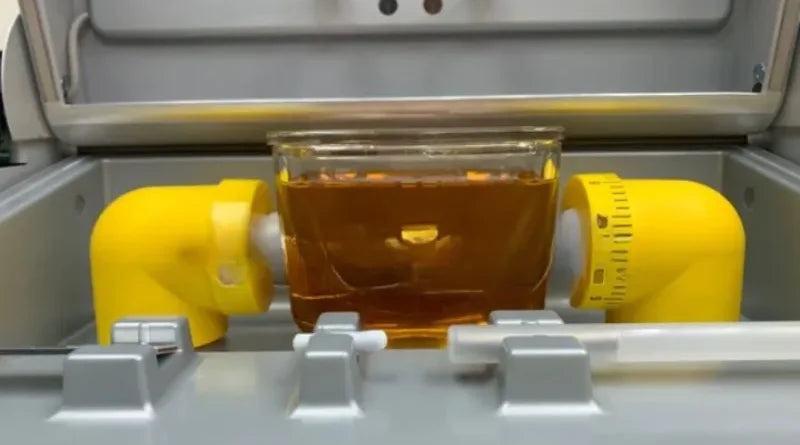

Device structure

- Connect the test equipment, including the high voltage source and meter, to the device under test (EUT).

Apply tension

- Gradually increase the voltage applied to the EUT while measuring the current and phase angle.

Data analysis

- Calculate the tan delta value by analyzing the phase difference between voltage and current.

- Compare the tan delta value obtained with baseline values or manufacturer specifications.

Interpret results

- Interpret the Tan Delta value to assess the condition of the insulation.

- Identify trends or changes in tan delta values over time for predictive maintenance.

Predicting test results

Interpreting Tan Delta test results requires a clear understanding of the values and their implications:

- A Tan Delta value of 0 indicates healthy insulation with minimal dielectric losses.

- Values between 0.001 and 0.1 may indicate some aging or contamination but are generally acceptable.

- Values above 0.1 indicate possible problems such as moisture ingress, contamination or insulation deterioration.

What are the different Tan Delta test modes?

The Tan Delta test can be performed in different modes, each serving specific purposes:

Offline mode

- Purpose : Used during routine maintenance or factory testing.

- Method: The device is offline and disconnected from the power source.

- Application : Assess insulation condition before placing equipment into operation or during scheduled maintenance.

Online mode

- Purpose : Continuous monitoring of equipment in real time.

- method : Testing is performed while the device is in operation.

- Application : Detects insulation problems as they occur and enables immediate corrective action to prevent failures.

Partial discharge coupling mode

- Purpose : Detection of partial discharges in insulation.

- method : Combination of tan delta tests with partial discharge measurements.

- Application : Finding and evaluating partial discharge activity can be a harbinger of an insulation failure.

Applications of the Tan Delta Test

The Tan Delta test finds application in various sectors and scenarios where electrical insulation is critical. Here are some key areas where this testing is essential:

Electricity generation and transmission

High voltage transformers and cables are exposed to extreme conditions in power plants. Tan Delta's regular testing helps ensure the reliability of these critical components and minimizes the risk of power failure.

Electricity supply

Utilities rely on tan delta testing to evaluate the insulation condition of power distribution equipment, including panels and circuit breakers. Early detection of problems can prevent equipment failures that can knock out power.

Industrial facilities

Factories often contain a lot of electrical equipment, and tan delta testing is essential to ensure the proper functioning of motors, generators, and other machines. Predictive maintenance based on tan delta results can save significant costs.

Renewable energy

The renewable energy sector, which includes wind turbines, solar inverters and grid connections, uses tan delta testing to maintain the reliability of equipment exposed to adverse environmental conditions.

Railway and transport

Tan Delta tests are essential in rail and transportation systems to assess the insulation conditions of overhead lines, power distribution systems and signaling systems to ensure passenger safety and operational continuity.

oil and gas

Offshore and onshore oil and gas installations rely heavily on electrical equipment for drilling, production and processing. Tan Delta testing is essential to ensure operations in these demanding environments.

Data Center

In data centers where uninterrupted power supply is critical, Tan Delta tests help maintain the functionality of backup generators, UPS systems, and power distribution infrastructure.

Conclusion

The Tan Delta test is a powerful diagnostic tool that plays a crucial role in maintaining the integrity of electrical insulation in various industries. Its ability to detect early signs of insulation deterioration and predict potential failures makes it invaluable in ensuring reliability and safety. By understanding the principles, methods and applications of Tan Delta testing, companies can proactively manage their electrical assets, minimize risk and ensure uninterrupted operations in today's high voltage environments.

Common questions

1. Which devices can be subjected to tan delta testing?

The Tan Delta test is suitable for various high voltage devices including transformers, cables, generators and bushings.

2. How often should the tan delta test be performed?

The frequency of tan delta testing depends on factors such as device type, age, and criticality. They are generally performed during scheduled maintenance or as part of a preventive maintenance program.

3. Are there international standards for tan delta testing?

Several international standards, such as IEEE and IEC, provide guidelines for carrying out tan delta tests and interpreting the results, ensuring consistency and reliability in the assessment of insulation conditions.