Mobile Operated Robot is a Robot whose movement can be controlled by pressing the mobile phone number. The robot can move forward, backward, right or left depending on the numbers you are pressing. The property of the robot to operate by cell phone helps you to operate the robot from some distance. The robot controlled by mobile phone uses DTMF (dual tone-multifrequency) module. It is capable of receiving a set of commands (instructions) in the form of DTMF (Dual Tone Multiple Frequency) tones and carrying out the necessary actions. The robot is controlled by making calls to the cell phone connected to the robot. The robot performs various operations such as moving forward, backward, etc. if any key is pressed during the call, listening on the other side of the call (that is, on the cell phone connected to the robot). Each key corresponds to a specific frequency which is decoded by the DTMF decoder and processed by the logic circuit, giving each key a specific operation such as forward, backward, right, left, etc. with the working range as wide as the service provider's coverage area .

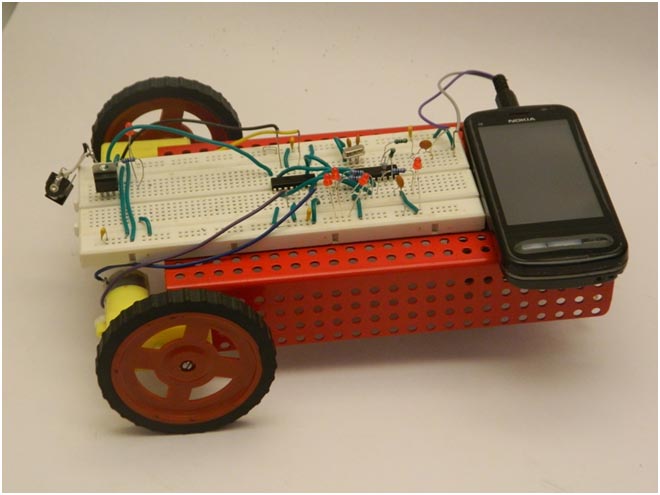

Fig. 1: DTMF-based mobile operated robotic car prototype

Block diagram

Fig. 2: Block diagram of DTMF-based mobile-operated robotic car

Cell phone controlled robots are used to operate the robot using the cell phone. By connecting the cell phone to the circuit, the cell phone can control the robot through the cell phone keyboard.

Stage 1

Cell phone

The cell phone is used to give instructions to the robot by pressing the cell phone keypad. The output of the cell phone controlled robot is dual tone frequency which is received by the DTMF receiver.

Stage 2

DTMF Receiver Section

The DTMF receiver section is used to receive the double tone coming from the cell phone. It is received by DTMF and decoded by the same DTMF IC and delivered to the next circuit.

IC DTMF

To receive the dual tone frequency from the cell phone and convert it into usable signal, we use IC HT9370. Here we get an explanation of IC HT9170. Both ICs are compatible with each other.

IC HT9170

HT9170 is the series of Dual Tone Multi Frequency ( DTMF ) receivers. They employ digital counting techniques to detect and decode the 16 DTMF tones into a 4-bit output code. The HT9170 series receivers do not require external filters as they use high precision switched capacitor filters to filter low and high frequency signals from DTMF tones. They also support shutdown (PWDN) and inhibit (INH) modes. PWDN mode is used to turn off the crystal, while INH mode to inhibit DTMF tones A, B, C and D. The clock is provided by a 3.58 MHz crystal.

In simple terms, the HT9170 IC detects and decodes the 16 DTMF tones into a 4-bit output. If tones are not detected, the four output bits remain low. The DV pin goes high on detection of a valid tone.

Pin Diagram:

Fig. 3: HT9170 DTMF Receiver IC Pin Diagram

Pin Description:

|

Pin No |

Function |

Name |

|

1 |

Op-amp non-inverting input |

Vice president |

|

two |

Inverted op amp input |

VN |

|

3 |

Operational amplifier output terminal |

GS |

|

4 |

Reference voltage output terminal |

V REFERENCE |

|

5 |

High active. Inhibits the detection of tones corresponding to A, B, C and D. It is internally pulled down. |

INH |

|

6 |

High active. This puts the chip into shutdown mode and inhibits the oscillator. It is internally pulled down |

PWDN |

|

7 |

Connection for standard 3.579545 MHz crystal |

X1 |

|

8 |

X2 |

|

|

9 |

Earth (0V) |

V SS |

|

10 |

High active; Enables output D0-D3 |

OE |

|

11 |

Output terminals |

D0 |

|

12 |

D1 |

|

|

13 |

D2 |

|

|

14 |

D3 |

|

|

15 |

Valid data. Increases valid DTMF signal reception; otherwise it remains low |

DVD |

|

16 |

Early steering exit |

Husa |

|

17 |

Tone acquisition time and release time can be set using external resistor and capacitor |

TR/GT |

|

18 |

Supply voltage; 5V (2.5V-5.5V) |

TRUE |

Motorized driving internship

Step 3

Motorized driving internship

In this step the L293D IC motor driver is used to drive the motor. As the signal comes from the inverter IC, it drives the motor according to the incoming signals.

IC L293D

L293D is a dual H-bridge motor driver integrated circuit (IC). Motor drivers act as current amplifiers in that they receive a low current control signal and supply a higher current signal. This higher current signal is used to drive the motors.

L293D contains two integrated H-bridge driver circuits. In their common mode of operation, two DC motors can be driven simultaneously, both in the forward and reverse directions. Two-motor motor operations can be controlled by input logic on pins 2 and 7 and 10 and 15. Input logic 00 or 11 will stop the corresponding motor. Logics 01 and 10 will rotate it clockwise and counterclockwise, respectively.

The enablement of pins 1 and 9 (corresponding to the two motors) must be high for the motors to start operating. When an enable input is high, the associated driver is enabled. As a result, the outputs become active and work in phase with their inputs. Likewise, when the enable input is low, this driver is disabled and its outputs are turned off and in a high impedance state.

Fig. 4: L293D Motor Driver IC Pin Diagram

Truth table for robot motion

|

Mr. No |

IN 1 |

IN 2 |

IN3 |

IN4 |

Robot movement |

|

1 |

1 |

0 |

0 |

1 |

Advance |

|

two |

1 |

1 |

1 |

1 |

To stop |

|

3 |

1 |

0 |

1 |

0 |

Left |

|

4 |

0 |

1 |

0 |

1 |

Right |

The signal logic will change according to the condition.

Steps to build the cell phone controlled robot

Accessories needed to make a cell phone controlled robot

|

Mr. No. |

Component name |

Amount |

| 1. | Double holder for AA batteries | 1 |

| two. | Chassis (robotic platform) | 1 |

| 3 | Test board | 1 |

| 4 | Clamp | 1 |

| 5. | Stripper | 1 |

| 6. | A central thread | As per use |

| 7. | Nose pliers | 1 |

| 8 | Screwdriver | 1 |

Mechanical assembly of robotic chassis

Step 1:

Get a robotic chassis.

Fig. 5: Representational Image of the Robot Main Chassis

Step 2:

Take the BO motor as shown in the diagram.

Step 3:

Fig. 6: Image showing the motor attachment to the robot chassis

Take an M2.5 screw (25) to fit the BO motor to the chassis. Mount the motor in the upward direction as shown in the figure. Here the last hole in the chassis is used to fit the engine.

Observation

Here I kept the M2.5 engine screw (25) in separate polyethylene and also do not mix it with another screw.

Fig. 7: Image showing the motor attachment on both sides of the robot chassis

Step 4

Fig. 8: Image showing the attachment of the wheels to the robot motors

Fit the two wheels onto both motor axles as shown in the figure. Secure the engine with self-tapping red wheel bolt.

Step 5

Fig. 9: Representational image of the rotating wheel and strip for the robot

Take the caster wheel and caster wheel strap as shown in the diagram.

Step 6

Fig. 10: Image showing the fixation of the rotating wheel on the robot strap

Insert three M3 -10 screws into the castor wheel. Now fit the caster wheel to the caster wheel strap in the outward direction as shown in the figure.

Step 7

Now fit the caster wheel strip to the middle position of the chassis as shown in the diagram using two M3-10 screws.

Now your robotic platform is ready to use.

Fig. 11: Image showing the fastening of the swivel wheel strap to the robot chassis

Breadboard connection

Fig. 12: Image showing rows and columns on a breadboard

· Provide +5 volt positive power on the first line.

· Connect GND to the second line of the breadboard.

· Connect +5 volts from the top line with the line below to make the line below +5 volts.

Connect the upper GND line with the lower GND line to form the GND line of the line below.

· Short the middle lines below by connecting the +5 volt line to +5 volt and the ground line to the ground line.

Fig. 13: Typical breadboard image

Construction of cell phone-controlled robot on breadboard

· Power supply

· Driver

· DTMF module

Designing the power supply section

Power supply

General description

The power supply is used to supply power to the entire circuit assembly. The below components are used to make the power supply section.

List of components for power supply

|

Mr. No. |

Component name |

Component list |

| 1 | DC socket | 1 |

| two | 7805 voltage regulator IC | 1 |

| 3 | 3mm LED | 1 |

| 4 | Resistor (220?) (Red, Red, Black, Black) | 1 |

Component Explanation

Make the connection below for power supply as shown in the image below.

DC socket

Fig. 14: Typical image of DC Jack

Fig. 15: DC connector pin diagram

7805 Connection Pin Diagram

|

Mr. No |

Pin 7805 No |

Pin name 7805 |

|

1 |

Pin 1 |

+12 volts (battery supplied) |

|

two |

Pin 2 |

Gnd |

|

3 |

Pin3 |

+5 (output to supply the entire circuit) |

Referring to the images below you can make the power supply circuit

1. Breadboard Image

Fig. 16: Representational image of the power supply circuit on the breadboard

2. Schematic diagram for power supply

Fig. 17: Robot power supply circuit diagram

Testing the power supply section

Fig. 18: Representational image of the motor driver circuit on the breadboard

If the LED lights up, it means the power supply circuit connection is correct. and now you can give power to the entire assembly.

Designing the Motor Driver Section

Motor Driver Section

General description

You have now created a motor driver section that is used to drive the motor. Here to drive the motor you use L293D IC.

Component list for motor driver section

|

Mr. No |

Component name |

| 1. | Section IC L29D3 |

| two. | A central thread |

Motor driver section design

By referring to the images and table below you can make and test the motor driver section.

L293D pin connection

|

Mr. No |

Pin L293 D |

supply voltage |

| 1 | Pin #1 | +5 volts |

| two | Pin #9 | +5 volts |

| 3 | Pin #16 | +5 volts |

| 4 | Pin #8 | +12 volts |

| 5 | Pin #4 and 5 | Gnd |

| 6 | Pin #12 and 13 | Gnd |

Motor connection with L293D IC

|

Mr. No. |

Output pins |

motor wire |

| 1 | o/p1 | First wire of the first motor |

| two | o/p2 | Second wire from the first motor |

| 3 | o/p3 | First wire from second motor |

| 4 | o/p4 | Second wire from second motor |

Breadboard image

Fig. 19: Representational image of the motor driver circuit on the breadboard

Motor driver section schematic image

Fig. 20: Circuit diagram of IC L293D based motor driver

Provide below power on input terminal of L293d IC to test the motor

|

Mr. No. |

Pin name |

Supply given |

|

1 |

In 1 |

+5 |

|

two |

In 2 |

Gnd |

|

3 |

Em3 |

+5 |

|

4 |

In4 |

Gnd |

Observation

· Short circuit between pins 4 (gnd) and 5 (gnd) with the jumper. The jumper can be removed from the wire.

· In the same way, also short pins 12 (gnd) and 13 (gnd) of IC l293D.

Motor Driver Section Test

Step 1

Connect a wire from the first motor to the o/p1 pin of the L293D IC. And the second is with the second o/p2 of IC L293D.

The motor should rotate clockwise from the front. If the motor turns counterclockwise, turn it clockwise by swapping its wire to the L293D o/p pins.

Step 2

Connect a wire from the second motor to the o/p3 pin of the L293D IC. And the second with the second o/p4 of the L293D IC.

Now the motor should rotate counterclockwise from the front. If the motor turns clockwise, do so counterclockwise by swapping its wire to the L293D o/p pins.

DTMF Module

Now the chassis must be moved forward.

DTMF Module

General description

DTMF modules are used to receive the signal from the cell phone and control the robot through the output signal from the DTMF IC.

DTMF Module

To make the DTMF module, the following components are required.

The component required to make the logic circuit is shown in the table below.

|

Mr. No. |

Component name |

Amount |

| 1. | IC HT9370 | 1 |

| two. | 3.57 Hz crystal | 1 |

| 3. | LED (5mm) | 4 |

| 4. | 10 thousand? R9 (brown, black, black, red) | 4 |

| 5. | 100 thousand? R8 (brown, black, black, orange) | two |

| 6. | Capacitor C1 and C2 (33pF) Ceramic capacitor | two |

| 7. | Capacitor C4 (104) Ceramic Capacitor | 1 |

| 8. | Capacitor C5(104) Ceramic Capacitor | 1 |

| 8. | 330k (orange, orange, black, orange) | 1 |

| 9. | Audio input | 1 |

Component Explanation

Audio input

Fig. 21: Typical audio jack image

Audio connectors are used to connect the cell phone to the DTMF circuit.

Open the audio jack and connect the longer terminal (GND) with the ten-core wire and the smaller terminal on the left side (input terminal) with another ten-core wire.

Fig. 22: Image showing the internal wiring of the audio connector

Connect the input pin to one terminal of the capacitor and the other to the GND terminal.

Connection of the IC section of the DTMF Module

|

Mr. No |

Fix no |

Component connection |

| 1 | 1 | Short with pin #4 |

| two | two | 100 k resistor and 104 capacitor |

| 3 | 3 | 100k resistor with pin #2 |

| 4 | 5 | Short with pin #9 |

| 5 | 6 | Short with pin #9 |

| 6 | 7 and 8 | 3.57MHz Crystal |

| 7 | 10 | + 5 volts |

| 8 | 11,12,13,14 | 10k resistor with positive terminal of the LED |

| 9 | 15 | Open |

| 10 | 16 | 330 thousand Resistant |

| 11 | 17 | 104 capacitors |

| 12 | 18 | +5 volts |

Also make the connection below

· Make a short between pins 1 and 4 and also make a short between pins 5 and 9 and 6.

· Connect one terminal of the 100k resistor with pin #2 and another terminal with the capacitor terminal 104 and another terminal with the audio jack input.

· Connect one 100k terminal to pin #3 and another terminal to pin #2.

· Connect the 3.57 MHz crystal to pins 7 and 8 and also connect one terminal of two 33pf capacitors to the crystal and another terminal to gnd.

· Give + 5 volts to pin no. 10 of the IC.

· Connect pin 11,12,13,14 with one terminal of the 1k resistor and another terminal with the positive terminal of the LED and its negative terminal with GND.

· Pin #15 remains open.

· Pin #16 with one terminal of the 330 k resistor and another terminal with pin #17.

· Connect pin #17 with one terminal of capacitor 104 and it's other terminal pin with +5 volts.

· Give +5 volts to pin #18.

· Connect the audio connector input wire with capacitor 104 and another GND with GND pin on the breadboard.

1. DTMF module breadboard image

Fig. 23: Representational image of the DTMF decoder circuit on the breadboard

2. Schematic layout of the DTMF Module section

Fig. 24: Circuit diagram of CM8870CP IC based DTMF receiver

Circuit troubleshooting

· Check the continuity of the entire circuit by placing the multimeter in continuity mode .

· Also check the voltage at different points of the circuit using the multimeter. Also check the voltage on the different pins of the IC.

· Connect the 0.1 µf capacitor between the +5 and Gnd pins at any random location on the breadboard.

· You can check the crystal frequency in CRO. It should reach approximately 3.57 MHz.

· You can also check the waveform of the audio signal coming from the cell phone in CRO. See the image below coming from the audio signal coming from the cell phone.

Fig. 25: Image of cell phone audio signals displayed on a CRO

Circuit diagram and complete assembly

Fully Connected Circuit for Mobile Phone Controlled Robot

Breadboard image

Fig. 26: Representative image of the complete control circuit for Robot on Breadboard

Schematic image

Fig. 27: Circuit Diagram of Mobile Operated Non-Microcontroller Robot

Motor connection with L293D IC

|

Mr. No. |

Output Pins |

motor wire |

| 1 | o/p1 | First wire of the first motor |

| two | o/p2 | Second wire from the first motor |

| 3 | o/p3 | First wire from second motor |

| 4 | o/p4 | Second wire from second motor |

Connection of the DTMF module output to the IC L293D

Here Q1, Q2, Q3, Q4 represent the output of the DTMF module.

| Mr. No |

DTMF output |

L293D output |

|

1 |

1st quarter |

IN 1 |

|

two |

2nd quarter |

IN 2 |

|

3 |

3rd trimester |

IN3 |

|

4 |

4th quarter |

IN4 |

Robotic platform movement

· The movement of the robotic platform depends on the connection of the motor with the IC L293D.

· Insert the audio jack into the cell phone and check the headphone indication on the cell phone screen.

· Open keyboard window and send any key like 1,2,3.4 etc.

· Press any key on your cell phone such as 1,2,3,4 and observe the robotic movement depending on the key pressed.

Complete assembly of cell phone controlled robot

Fig. 28: Representational image of the complete assembly of the mobile operated robot

· Also place the breadboard on the robotic platform.

· Also take a battery cell holder and place it on the robotic platform.

· You can power the robotic platform through the battery cell holder or using a 12 volt adapter.

Fig. 29: Mobile Operated Robotic Car Prototype