In the complex scenario of electrical energy systems, transformers are fundamental because they allow the efficient transmission and distribution of electricity. However, the reliability of these transformers is continually tested by the potential for failures that can lead to catastrophic failures. To protect these vital components from invisible dangers, protective devices such as the Buchholz relay prove to be indispensable sentinels. This relay, named after its inventor Max Buchholz, works at the core of oil transformers and serves as an early warning system against impending errors. This article takes a comprehensive look at the Buchholz relay, decoding its distinctive operation, highlighting its crucial role in transformer protection, and highlighting its applications in various power system scenarios.

On this journey through the intricacies of the Buchholz relay, we delve into its basic operation, discovering the reasons behind its design and its critical role in preventing potential power distribution disasters. From basic components to applications that demonstrate their versatility, this article is intended to be a reliable guide for experienced professionals and anyone seeking a basic understanding of the importance of the Buchholz relay in transformer protection.

What is a Buchholz relay?

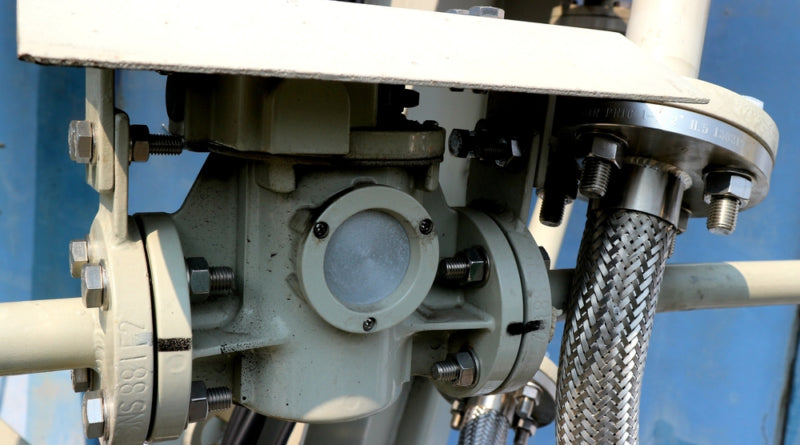

The Buchholz relay, named after its inventor Max Buchholz, is a protective device used in oil-filled transformers. Its main function is to detect and respond to imminent transformer failures to prevent major damage and ensure its longevity. The Buchholz relay is a reliable early warning system for various transformer failures, installed in the oil-filled expansion tank.

Buchholz Relay Components

Before we get into how it works, let's look at the main components of a Buchholz relay:

- Flood chamber: The float chamber in the expansion tank contains a float that moves in response to fault-induced changes in oil flow.

- Oil flow indicator: Monitors the oil flow in the transformer and signals anomalies that may indicate the development of faults.

- Alarm contacts: Activated when the float reaches a certain level and triggers an alarm to alert the operator of possible problems.

- Trip contacts: In case of serious errors, the Buchholz relay can disconnect the transformer, preventing further damage.

How does the Buchholz relay work?

The operation of the Buchholz relay is based on the principle that different types of faults in a transformer produce characteristic gas and oil flow patterns. These patterns are recognized by the relay, which reacts accordingly. Here's a step-by-step explanation of how it works:

- Normal operation: During normal transformer operation, the float in the Buchholz relay remains in its lower position, allowing oil to flow freely through the relay.

- Incipient disturbances: In the event of faults such as overheating, partial discharges or insulation failures, gases are produced in the transformer. The gas is lighter than oil and rises to the surface of the expansion tank, causing the float to rise.

- Floating movement: As the float rises, it activates the oil flow indicator and activates the alarm contacts. This early warning allows operators to investigate and resolve potential issues before they escalate.

- Fatal errors: Serious faults, such as internal short circuits or large insulation failures, will result in a rapid increase in gas production. This sudden increase in gas causes the float to rise quickly, activating the trip contacts and disconnecting the transformer from the electrical network.

Buchholz Relay Applications

The Buchholz relay is widely used in various transformer applications and contributes significantly to system reliability. Some important applications are:

- Power transformers: The Buchholz relay used in large power transformers provides important protection against faults that could compromise the integrity of the transformer.

- Distribution transformers: The Buchholz relay is essential to prevent catastrophic failures and ensure uninterrupted power supply even with smaller transformers.

- Oil transformers: Due to its design and dependence on oil flow, the Buchholz relay is mainly used in oil transformers where gas evolution indicates possible failures.

Advantages of the Buchholz relay

- Early error detection: The Buchholz relay detects imminent faults and thus allows timely intervention and maintenance.

- Preventing catastrophic failures: By tripping the transformer during severe faults, the relay prevents extensive damage and minimizes downtime.

- Cost-effective protection: Given the potential costs associated with transformer failures, the Buchholz relay represents a cost-effective protection solution.

Challenges and Considerations

Although the Buchholz relay is a robust protection device, certain challenges and factors must be taken into consideration:

- False alarm: External factors such as temperature fluctuations or small oil leaks can trigger false alarms, requiring careful monitoring and calibration.

- Maintenance requirements: To ensure the proper functioning of the Buchholz relay, regular maintenance is essential. This also includes regular checks of float movement and alarm/trip contacts.

- Compatibility: The suitability of the Buchholz relay depends on the transformer design and type and requires in-depth knowledge of the specific application.

Conclusion

In summary, the Buchholz relay is an indispensable protection in the dynamic field of transformer protection. Its importance lies in its ability to detect early failures and its role as a proactive safeguard against potential catastrophic failures. As an integral part of oil transformers, it is a vigilant sentinel that constantly monitors oil flow and gas formation to trigger timely warnings. The relay's versatility extends to diverse applications, from large power transformers to smaller distribution transformers, confirming its universal relevance. While challenges such as false alarms and maintenance requirements persist, the Buchholz Relay's unparalleled contribution to the reliability and longevity of electrical power systems remains undeniable, cementing its position as a cornerstone in protecting critical infrastructure.

Common questions

1. How often should the Buchholz relay be checked and maintained?

To ensure effective operation of the Buchholz relay, regular testing and maintenance are of utmost importance. Industry standards recommend performing thorough inspections at least once a year. This routine check includes checking the float movement, checking the alarm and trip contacts, and checking the overall responsiveness of the relay. Critical applications may require more frequent testing to resolve potential issues immediately.

2. Is it possible to retrofit the Buchholz relay in existing transformers?

Yes, retrofitting the Buchholz relay on existing transformers is often a viable option. However, transformer design and relay compatibility must be carefully examined. Working with experienced professionals during modernization ensures seamless integration and improves transformer protection capabilities without compromising existing functions.

3. Are there alternative protection devices to the Buchholz relay?

Although the Buchholz relay is a widely used protection device, there are alternatives. Pressure relief devices and gas detectors are alternatives used in certain applications. However, the choice between these devices depends on factors such as the transformer design, the level of sensitivity required and the specific failure scenarios expected. Each protective device has its own benefits and considerations, so the choice must be tailored to the unique characteristics of the power system in question.