-

Incentivos Fiscais de R$ 3,8 bilhões em 2025: Programa Mover na Indústria Automotiva

Em um cenário de constante evolução e desafios, a indústria automotiva brasileira recebe um impulso significativo com a implementação do programa Mover. Esse decreto regulamentador prevê a concessã...

-

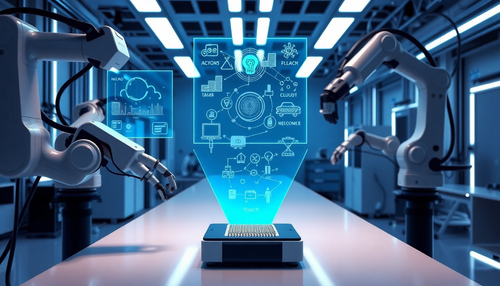

Futuro da Indústria Automotiva: Tendências Tecnológicas Transformando o Setor

O setor industrial está passando por uma transformação acelerada, impulsionada por avanços tecnológicos que estão remodelando a maneira como as empresas operam, produzem e interagem com seus client...

-

Futuro da Mobilidade Automotiva no Brasil: Veículos Elétricos e Autônomos em 2025

Em 2025, a indústria automotiva brasileira está vivenciando uma transformação significativa, com o crescimento acelerado dos veículos elétricos, híbridos e autônomos. Essa revolução na mobilidade e...

-

A Revolução Tecnológica na Fábrica da Nissan em Resende

A Nissan, uma das principais montadoras do mercado automotivo brasileiro, acaba de concluir uma impressionante modernização de sua fábrica localizada em Resende, no estado do Rio de Janeiro. Esse i...

-

Setor Automotivo Brasileiro registra crescimento de 8% nas vendas no primeiro trimestre

O setor automotivo brasileiro tem vivido um momento de recuperação e crescimento nos últimos meses. De acordo com os dados mais recentes, as vendas de veículos no país registraram um aumento de 8% ...

-

Rodovias de Aço: A Revolução da Recarga Elétrica em Movimento

A revolução dos veículos elétricos está em pleno andamento, e com ela surge uma nova demanda: a necessidade de uma infraestrutura de recarga eficiente e acessível. É neste cenário que as rodovias d...

-

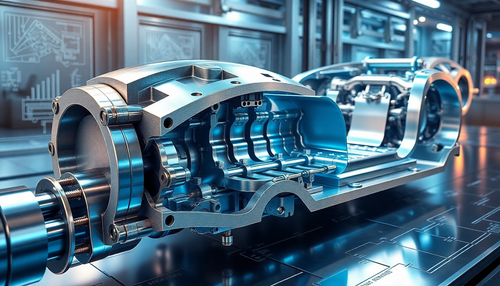

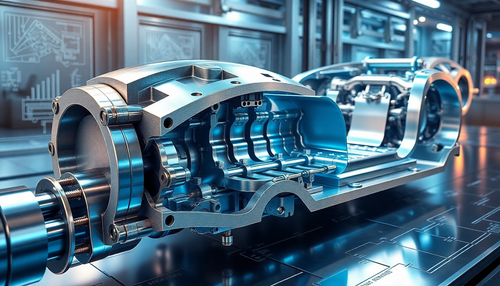

Chassis de Aço Inteligente: A Revolução da Segurança Autônoma

Em um mundo em constante evolução, a indústria automotiva está à beira de uma transformação revolucionária. Com o avanço da tecnologia, os carros autônomos estão se tornando uma realidade cada vez ...

-

Aços Avançados de Alta Resistência (AHSS) Revolucionando a Indústria Automotiva

A indústria automotiva está constantemente em busca de soluções inovadoras que permitam a fabricação de veículos mais leves, seguros e eficientes. Nesse contexto, os Aços Avançados de Alta Resistên...

-

Aço Reciclado impulsiona a Revolução das Motocicletas Elétricas

A indústria de motocicletas está passando por uma transformação revolucionária, com a adoção cada vez maior de veículos elétricos. Essa mudança é impulsionada não apenas pela crescente conscientiza...

-

Aço na Mobilidade Sustentável: Veículos Leves e Eficientes

A indústria automotiva enfrenta um desafio crucial: reduzir as emissões de carbono e melhorar a eficiência energética dos veículos, sem comprometer a segurança e o desempenho. Neste contexto, o aço...

-

Lecar, a nova estrela da indústria automotiva brasileira

A Lecar, uma empresa brasileira que está conquistando seu espaço no setor automotivo, acaba de anunciar planos ambiciosos para se tornar uma das principais fabricantes de veículos no país. Recentem...

-

A FIAT consolida sua liderança global em 2024

A FIAT confirma sua posição como marca líder da Stellantis em volume de vendas, dominando mercados importantes, como Brasil, Itália, Turquia e Argélia, com o Fiat Strada e Panda se destacando entre...

-

Tendências do Mercado Automotivo em 2024: Rumo a uma Mobilidade Mais Sustentável e Conectada

Uma análise de tendências de consumo no mercado automotivo em 2024 destaca a busca por marcas confiáveis, menor depreciação e custos reduzidos de manutenção, enquanto híbridos e elétricos despontam...

-

Revolução da Mobilidade Urbana: Ônibus Autônomos sem Mapas

No campo sonoro da robótica, a inovação constante é essencial para atender às necessidades de um mundo em rápida evolução. Um dos avanços mais fascinantes é a criação de sistemas de transporte públ...

-

Maior fábrica de Nióbio do mundo impulsiona a inovação em Baterias de Carregamento Ultrarrápido

Araxá, em Minas Gerais, é agora o local da maior fábrica de nióbio do mundo especializada em baterias de carregamento ultrarrápido. A unidade tem capacidade para produzir 2.000 toneladas por ano do...

-

Soluções poliméricas inovadoras apoiam a mineração de Lítio Sustentável

À medida que a demanda global por lítio continua a aumentar, impulsionada pelo aumento de veículos elétricos e tecnologias de energia renovável, os desafios de manutenção enfrentados pelas operaçõe...

-

Bio-Híbrido: Solução eficiente para a indústria automotiva

A chegada do Bio-Híbrido

Batizado de Bio-Híbrido, trata-se de um recurso eficiente, ajuda a economizar combustível e aumenta os preços dos SUVs compactos Pulse e Fastback em apenas R$ 2.000, ou sej...

-

Nissan e Mitsubishi Formam Nova Joint Venture para Mobilidade Autônoma e Elétrica

As gigantes japonesas Nissan e Mitsubishi, que estão ligadas por meio de suas participações na aliança com a Renault, formarão uma nova joint venture para fornecer serviços relacionados à direção a...

-

BID e BID Invest ampliam financiamento verde e climático na América Latina e Caribe

O Banco Interamericano de Desenvolvimento (BID) e seu braço para o setor privado, BID Invest, anunciaram recentemente uma ampliação significativa do foco na sustentabilidade climática e ambiental e...

-

Crescimento impressionante da Indústria Automotiva brasileira em 2024

O ano de 2024 tem sido um período de grande crescimento e otimismo para a indústria automotiva brasileira. Segundo os dados divulgados pela Associação Nacional dos Fabricantes de Veículos Automotor...

-

Toyota e Suzuki unem forças para lançar novo SUV Elétrico em 2025

Em uma movimentação estratégica no mercado automotivo, as gigantes Toyota Motor Co. e Suzuki Motor Corp. anunciaram uma colaboração histórica no segmento de veículos elétricos (EVs). O resultado de...

-

Mercado Global de Veículos Elétricos rumo ao Trilhão de Dólares

O mercado global de veículos elétricos (VEs) está em forte ascensão e deve atingir US$ 1 trilhão em receita até 2028, com um crescimento projetado de 27% nas vendas. Mesmo com obstáculos como infra...

-

Futuro dos Veículos Elétricos e Mobilidade: Desafios e oportunidades no Brasil

No final de 2022, a União Europeia local o acordo "Fit For 55", com o objetivo de encerrar as vendas de carros novos emissores de CO₂ na Europa até 2035. O anúncio fez com que vários montadoras glo...

-

Detectando falhas de baterias de Veículos Elétricos antes que seja tarde demais

As baterias em veículos elétricos podem falhar rapidamente, às vezes pegando fogo sem muito aviso. O Sandia National Laboratories está trabalhando para detectar essas falhas cedo e fornecer tempo d...

-

Bentley atrasa meta de oferecer apenas Veículos Elétricos para 2035

A marca britânica de ultra-luxo, pertencente ao grupo Volkswagen AG, adiou novamente sua meta de oferecer apenas veículos elétricos a bateria (BEVs) em cinco anos, agora para 2035. No entanto, plan...

-

O Primeiro Caminhão Híbrido Conceito do Mercado Nacional

A Volkswagen Caminhões e Ônibus e a Suspensys, uma das empresas de autopeças do Grupo Randon, está desenvolvendo o primeiro caminhão conceito híbrido do mercado nacional. O protótipo foi apresentad...

-

FPT Industrial investe R$ 127 milhões em novas tecnologias de propulsão

A FPT Industrial, marca integrante do Grupo Iveco dedicada ao design, produção e venda de motores, informou que irá investir R$ 127 milhões em pesquisa e desenvolvimento de novas tecnologias de pro...

-

Reciclagem de Baterias de Veículos Elétricos: O Papel de liderança da China

A China talvez esteja em uma posição privilegiada quando se trata de adoção de veículos elétricos (VE), respondendo por mais de 60% das vendas mundiais em 2022. Essa posição dominante a torna um pa...

-

Solução Inovadora para preservar a privacidade na internet dos Veículos

Cientistas afirmam ter desenvolvido uma ferramenta de inteligência artificial para consolidar a privacidade dos veículos e de seus motoristas. Como preservar a privacidade da chamada Internet dos V...

-

Avanço significativo em Baterias de Íons de Lítio: Cátodos ricos em Lítio com Vanádio

À medida que a demanda por veículos elétricos e sistemas de armazenamento de energia aumenta, as baterias de íons de lítio precisam fornecer densidades de energia mais altas a custos mais baixos. E...

-

Vendas de veículos automotores no Brasil atingem novo recorde em 2024

As vendas de veículos automotores no Brasil continuam em alta, com um crescimento expressivo de 16,4% no acumulado de janeiro a outubro de 2024 em comparação ao mesmo período do ano anterior. Segun...

-

Vendas de veículos no Brasil crescem 21,6% em outubro de 2024

A indústria automotiva brasileira registrou um desempenho positivo em outubro de 2024, com um aumento de 21,6% nas vendas de veículos em comparação com o mesmo mês do ano anterior. De acordo com os...

-

Reduzindo os Custos de Teste de Chips Automotivos com Machine Learning

Os chips acabados que vêm da fundição são submetidos a uma bateria de testes. Para aqueles destinados a sistemas críticos em carros, esses testes são particularmente extensos e podem adicionar de 5...

-

A Integração de Veículos Automatizados: Promovendo a Confiança dos Passageiros com Explicações Oportunas

A integração de veículos automatizados promete vários benefícios para a mobilidade urbana, incluindo maior segurança, redução de congestionamento de tráfego e acessibilidade aprimorada. Veículos au...

-

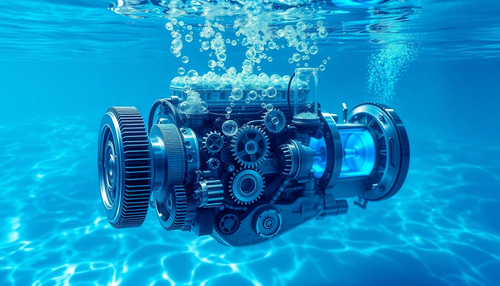

Motor a água da Toyota: Revolução Silenciosa da Mobilidade

A Toyota, uma das líderes do setor automotivo, acaba de apresentar uma inovação que pode redefinir o futuro dos transportes. Um motor movido a água, altamente eficiente e ecológico, promete não só ...

-

Toyota do Brasil anuncia expansão de fábrica em Sorocaba

A Toyota do Brasil acaba de anunciar uma grande expansão de sua fábrica em Sorocaba, no interior de São Paulo. Este investimento de R$ 11 bilhões faz parte do plano de investimentos da empresa para...

-

Combustíveis: Entendendo as Características e Propriedades

Combustíveis são quaisquer materiais que armazenam energia potencial em formas que liberam energia térmica ao queimar em oxigênio. O poder calorífico do combustível é a quantidade total de calor li...

-

Ascensão da BYD: Como a marca Chinesa está desafiando a Tesla

A BYD, marca que começou com a produção de baterias e hoje desafia gigantes globais, está mudando o cenário da indústria automotiva com uma trajetória que exemplifica o poder da inovação e da expan...

-

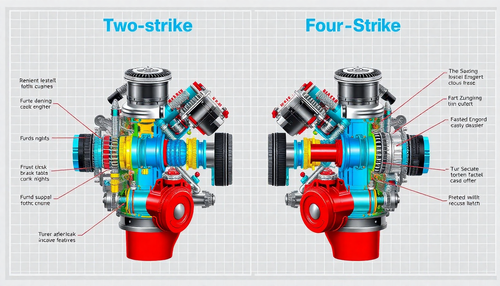

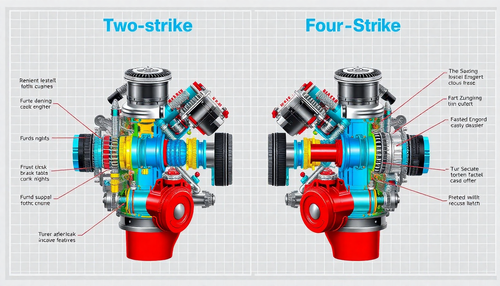

Motores de 2 Tempos vs. 4 Tempos: Entendendo as diferenças

Ao comparar o motor de 2 tempos com o motor de 4 tempos, é essencial entender o que diferencia esses tipos de motor. Cada um tem benefícios, aplicações e características de desempenho exclusivos, t...

-

Ecossistema de Aplicativos: 5 coisas essenciais para se ter dominio

Os ecossistemas de aplicativos estão se expandindo e se tornando mais complexos com o surgimento de aplicativos baseados em IA, esforços de modernização e novas iniciativas. Embora eu não ache que ...

-

Um avanço na ciência dos materiais pode ajudar a entregar uma nova geração de baterias acessíveis

A busca por baterias mais eficientes e acessíveis é um desafio constante na indústria de energia. Recentemente, uma equipe internacional de pesquisadores liderada por químicos da Universidade de Gl...

-

Caracterização de Baterias de Íons de Lítio com Ânodos de Silício usando Espectroscopia de RMN

Pesquisadores do Laboratório Nacional Argonne do Departamento de Energia dos EUA (DOE) desenvolveram e demonstraram um conjunto inovador de métodos para avaliar o envelhecimento a longo prazo em cé...

-

Fiat solidifica liderança no mercado Automotivo brasileiro em 2024

O mês de outubro de 2024 foi marcado por uma expressiva liderança da Fiat no mercado automotivo brasileiro. Com 20,9% de participação e 51.867 unidades emplacadas, a marca consolidou sua posição ta...

-

Carros Elétricos vs. Combustíveis Renováveis: Dilema da Sustentabilidade

Com recorde de vendas em 2024, os carros elétricos são promovidos como solução verde, mas especialistas questionam o impacto ambiental das baterias e a complexidade da reciclagem, abrindo espaço pa...

-

Jeep no mercado brasileiro: Liderança nos principais segmentos de SUVs

A Jeep encerrou o mês de outubro com 12.014 emplacamentos, marcando seu melhor desempenho de vendas nos últimos três meses. Com este resultado, a montadora atinge um total de 99.930 unidades comerc...

-

Waymo e o uso do Gemini na Direção Autônoma

A decisão da Waymo de utilizar o Gemini em seu sistema de direção autônoma é significativa por várias razões. Primeiro, ela representa uma mudança no uso de IA generativa e modelos de linguagem de ...

-

Indústria de Autopeças Brasileira projeta crescimento de 8% em 2024

A indústria de autopeças brasileira está se preparando para um ano de 2024 promissor, com projeções de faturamento revisadas e altas significativas em diversos segmentos. De acordo com o Sindicato ...

-

Stellantis acelera transformação com foco em eletrificação e adaptação aos consumidores

Em 2024, a Stellantis vem solidificando sua posição no mercado automotivo global com uma série de lançamentos estratégicos e foco em tecnologias multienergia. As novas plataformas STLA, desenvolvid...

-

Importância da Estamparia na Indústria Automotiva

Os carros são chamados de "máquinas que mudam o mundo". Como a indústria automobilística tem uma forte correlação industrial, ela é considerada um símbolo importante do nível de desenvolvimento eco...

Aimed at inverters for next-generation electric vehicles (EVs), the AE5 generation IGBTs will be mass-produced from the first half of 2023 on Renesas' 200 and 300 mm wafer lines at the company's factory in Naka, Japan. In addition Additionally, Renesas will increase production from the first half of 2024 at its new 300mm power semiconductor wafer fab in Kofu, Japan, to meet growing demand for power semiconductor products.

Aimed at inverters for next-generation electric vehicles (EVs), the AE5 generation IGBTs will be mass-produced from the first half of 2023 on Renesas' 200 and 300 mm wafer lines at the company's factory in Naka, Japan. In addition Additionally, Renesas will increase production from the first half of 2024 at its new 300mm power semiconductor wafer fab in Kofu, Japan, to meet growing demand for power semiconductor products.