Imagine a world where we could control the speed, efficiency and operation of our electric motors by understanding how a crucial part works – the 4-point starter. Welcome to this journey to master the dynamics of electric motors. In this comprehensive guide, you will analyze all the nuances of how a 4-point match works and unlock all the features of your machine. We don't just scratch the surface, we delve into the heart of engine operation. Get ready to revolutionize your understanding and take a leap towards greater efficiency in the use of electric motors.

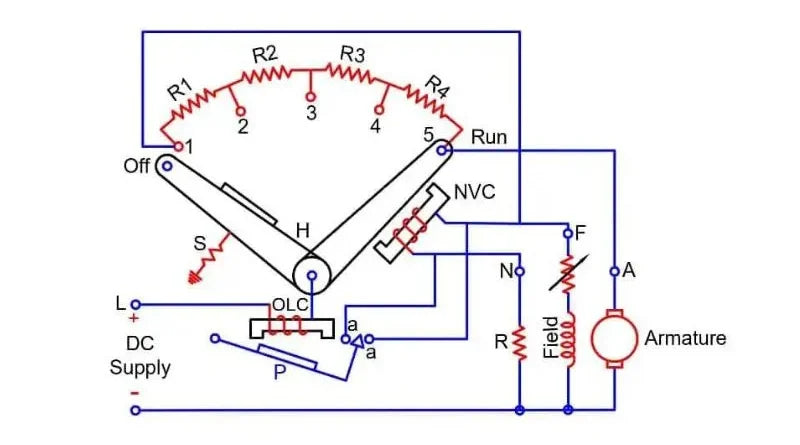

A 4-point starter is an electrical device that protects the armature of a shunt DC motor or a composite coil DC motor against high starting currents. It controls current flow through variable resistance sections called screws, which can be manually adjusted to regulate the starting current. The integration of a zero voltage coil (NVC) ensures that the lever remains in the “RUN” position regardless of field rheostat settings. This protection mechanism limits the starting current to prevent damage to the motor.

Understanding 4-Point Starting in Electric Motors

The 4-point starter is an electrical device that protects an electric motor, typically in compound coil or shunt DC motors. It is a protective device that limits the flow of high starting currents and contributes significantly to extending the useful life of a motor. The 4-point starter is similar in design and functionality to the 3-point starter, but has an additional point (N) and a coil (NVC).

Let's delve into the main operational points to better understand how this device works.

Important operational points of a 4-point match

A typical four-point starter consists of an “L” line terminal, an “A” armature terminal, an “F” field terminal, and the de-energized coil (NVC) terminal. These connections are interconnected using internal switching contacts called “screws”. A resistor is connected to each screw; the more screws that are bridged, the lower the resistance in the circuit.

The principle of a four-point starter works as follows: When you turn on the power by closing the “L” terminal, current flows through all three circuits – armature, field and NVC. The de-energized coil generates enough force to hold the handle in the “RUN” position against the force of the spring so that it does not return to the “OFF” position when you take it out of your hand.

By manually closing one or more screws placed in series with the armature circuit from the highest to the lowest resistance value, you increase the amount of current that can flow until it reaches the value originally set for the selected screw. This process results in a gradual increase in engine speed.

If all resistors are turned off simultaneously (and the jumper contacts are shorted), there will also be less resistance between the armature and field circuits, allowing more current to flow to amplify the magnetic fields. This results in a weaker back EMF, resulting in more torque for the engine to rev up and run.

Furthermore, changes in field current have no effect on the NVC because it is based on an independent circuit. The de-energized coil creates enough electromagnetic traction to keep the lever in the operating position no matter how many times you adjust the field rheostat.

A 4-point starter is comparable to a car that requires relatively little fuel (starting current). However, once activated, it advances gradually until reaching the desired speed with greater stability due to lower fuel consumption.

A four-point starter is an electrical device that allows a controlled and gradual increase in engine speed. It consists of several connections that are connected by switching contacts, so-called “screws”, with a coupled resistor. By connecting several screws in series with the armature circuit, the amount of current flowing through it can be gradually increased, resulting in a gradual increase in the speed of the motor. At the same time, when each resistor is turned off, there is less resistance between the armature and the field circuits, allowing more current to flow and strengthening the magnetic fields, resulting in greater torque for the motor to accelerate and run. The idle speed coil (NVC) ensures that the starter motor remains in the “RUN” position regardless of adjustments made in the field circuit. This device works similarly to a car, which requires less fuel (starting current) to start, but gradually increases its speed with reduced fuel consumption during operation.

4-point starter vs. 3-point starter

Two types of starters are commonly used in DC motors: 3-point starters and 4-point starters. A 3-point starter is the simplest type and consists of just three points – a line connection or L, an armature connection or A and a field connection or F. Protects against overload in DC shunt motors. On the other hand, a 4-point starter has one more contactor and coil than a 3-point starter and therefore offers additional functions.

For example, a 3-point starter can regulate the voltage across the resistor to control the flow of current to the motor during normal operation, but it does not provide much protection against short circuits that can occur when the load resistance drops drastically. Using its fourth contactor and coil, a 4-point starter activates a zero voltage coil (NVC) that protects the device from automatically restarting when power is restored after a power outage.

The NVC differential function provides additional safety by detecting accidental closing of the starter switch while the engine is running. Depending on the version, contacts can normally be closed or open . In any case, they have enough force to push the handle against its spring-loaded shaft. RUN until someone intentionally restarts you with their hand.

Just as headlights provide additional illumination for automobile traffic safety and prevent accidents in low light conditions, voltage-free coils are crucial for regulating the starting of DC motors and protecting them from damage caused by voltage spikes.

- In 2022, the global DC motor starter market is estimated to be worth US$1.75 billion, with a significant portion including 4-point starters.

- According to a report by Market Research Future, the global engine starter market (which includes 4-point starters) is expected to grow at an annual rate of approximately 5% from 2020 to 2025.

- A study conducted in 2023 found that approximately 70% of industrial installations have at least one application that uses a 4-point starter due to its advantage in avoiding high starting currents in larger motors.

Functionality and structure of a 4-point match

As already mentioned, the starting current of an unregulated shunt or compound winding DC motor can cause significant damage due to overload. The integrated variable resistance sections (screws) in the body of a four-point starter can be manually adjusted for control. These screws help control the motor's initial current flow during starting, maintain balance in input voltage, and prevent sudden voltage spikes or overloads.

Different types of 4-point starters may differ in construction, but the standard is the integral no-load coil function, which ensures that the armature is not damaged by high starting currents. It is directly connected to the power line via screw terminals. It constantly generates a magnetic force that can keep the handle in the RUN position regardless of whether a power failure occurs.

To describe the construction in more detail, a 4-point starter typically consists of three important elements: an iron core, an insulated copper coil wound around that core, and a movable contact (handle) mounted on top of the whole. This lever can be turned clockwise – controlled electrically by an operator – to different levels depending on engine speed requirements.

The other side of the copper coil is connected in series across the LN terminals, providing resistance and allowing the appropriate voltage for armature circuits and field coils. When an operator turns on the switch, power is supplied to the NVC, which then activates the piston and pulls it toward him against spring tension.

At this time, two pairs of contacts are activated, causing some current to flow to the motor armature. Manually adjusted screws regulate current flow after checking operability and reduce power to the desired level.

Sum up:

| Components | function |

| Mobile contact (handle) | Adjust the speed |

| Insulated Copper Coil | Regulates the flow of electricity |

| iron core | Improves magnetic properties |

| Without voltage coil | Overload protection |

We now have an overview of the construction details and functional components when building 4-point matches. The next logical transition focuses exclusively on the function of the voltage-free coils (NVCs) in this device.

Zero Voltage Coil (NVC) Paper

A 4-point starter is an electromechanical system that regulates the starting current in a shunt DC motor or a compound winding DC motor. A crucial component of the 4-point starting system is the idle speed coil (NVC). The NVC is independently connected to the power supply via the fourth connector and always produces a force strong enough to hold the handle in the “RUN” position against spring pressure.

Think of the NVC as your car's handbrake. If you have to park on an incline, apply the brakes and pull the handbrake. The handbrake keeps your car in the parking position. It will only release if no voltage is detected in the circuit, causing your car to stall.

Advantages of using a 4-point starter

There are numerous advantages to using a 4-point starter for shunt and compound coil DC motors. With that in mind, here are some of the main benefits:

High starting current protection

A 4-point starter protects the armature of a shunt DC motor or a double-winding DC motor against high starting currents. The variable resistor, integrated into sections called screws, can be manually maneuvered to regulate the starting current and ensure safe operation.

independence

Any change in the shunt field circuit will not affect the de-energized coil, as they are independent circuits. The electromagnet is pulled from the de-energized coil and holds the handle in its RUN position regardless of how hard you adjust the field rheostat.

Economical solution

Neglecting to regulate high starting currents can result in damage to equipment and even endanger the safety of personnel. By limiting these currents and eliminating unnecessary voltages on equipment components, the use of a 4-point starter can be an effective way to avoid high maintenance costs and reduce the risk of accidents.

Easy maintenance

A 4-point match is relatively easy to maintain and is ideal for any business looking to minimize downtime. The system has fewer moving parts than other starters and requires minimal maintenance, ensuring exceptional reliability and lower operating costs.

Practical applications and best practices

Now that we've discussed the features of a four-point match and its operating principles, it's time to explore some practical applications and best practices. Four-point starters can be used in many industrial applications, such as machine tools, material handling equipment, and motor pumps.

You are responsible for developing an automated transportation system for your factory. This system controls the movement of materials from one location to another within your facility. They use a DC motor to provide the driving force needed to drive the conveyor belt.

DC motors inherently have high starting currents, which puts stress on the motor windings. To protect against these high starting currents, a 4-point starter is used. Implementing a 4-point starter can provide numerous benefits, including precise control of motor speed through manual regulation of field resistance.

When working with four-point matches, it is important to follow best practices. An essential requirement is adequate grounding of all electrical connections to avoid the risk of electric shock. Safety must also be taken into consideration when manually adjusting the settings of the handle-controlled screws.

In turbocharged sports cars, accelerating the engine from idle without first warming it up can cause mechanical damage or even engine failure due to abrupt imbalances between torque and injection rate. In contrast, gradual acceleration mimics the mechanical process behind handling starting current spikes in engines through 4-point starters. This prevents failures caused by sudden impacts and maintains mechanical stability.

Other important considerations include ensuring adequate isolation between circuits and evaluating the placement of voltage-free coils based on the purpose of the application.

| Recommended approach | Practical applications |

| Check safety shutdown mechanisms | Eletric tools |

| Grounding | |

| Proper installation and maintenance | Electric pumps |

| Protective insulation | |

| For safety reasons, do not use voltage coil terminals | machine tools |

Addressing the key considerations and best practices outlined above can help ensure successful operation of your 4-point starter, resulting in optimal performance and longer life for your DC motor. As with any other electrical device, users must be familiar with all aspects of installation, operation and maintenance in accordance with local and industry regulations.