-

Incentivos Fiscais de R$ 3,8 bilhões em 2025: Programa Mover na Indústria Automotiva

Em um cenário de constante evolução e desafios, a indústria automotiva brasileira recebe um impulso significativo com a implementação do programa Mover. Esse decreto regulamentador prevê a concessã...

-

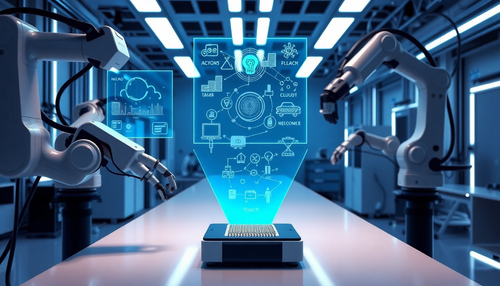

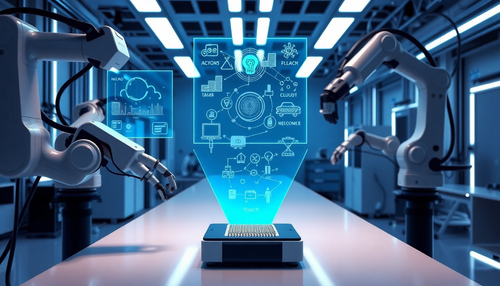

Futuro da Indústria Automotiva: Tendências Tecnológicas Transformando o Setor

O setor industrial está passando por uma transformação acelerada, impulsionada por avanços tecnológicos que estão remodelando a maneira como as empresas operam, produzem e interagem com seus client...

-

Futuro da Mobilidade Automotiva no Brasil: Veículos Elétricos e Autônomos em 2025

Em 2025, a indústria automotiva brasileira está vivenciando uma transformação significativa, com o crescimento acelerado dos veículos elétricos, híbridos e autônomos. Essa revolução na mobilidade e...

-

A Revolução Tecnológica na Fábrica da Nissan em Resende

A Nissan, uma das principais montadoras do mercado automotivo brasileiro, acaba de concluir uma impressionante modernização de sua fábrica localizada em Resende, no estado do Rio de Janeiro. Esse i...

-

Setor Automotivo Brasileiro registra crescimento de 8% nas vendas no primeiro trimestre

O setor automotivo brasileiro tem vivido um momento de recuperação e crescimento nos últimos meses. De acordo com os dados mais recentes, as vendas de veículos no país registraram um aumento de 8% ...

-

Rodovias de Aço: A Revolução da Recarga Elétrica em Movimento

A revolução dos veículos elétricos está em pleno andamento, e com ela surge uma nova demanda: a necessidade de uma infraestrutura de recarga eficiente e acessível. É neste cenário que as rodovias d...

-

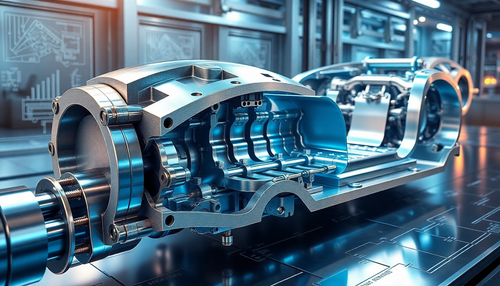

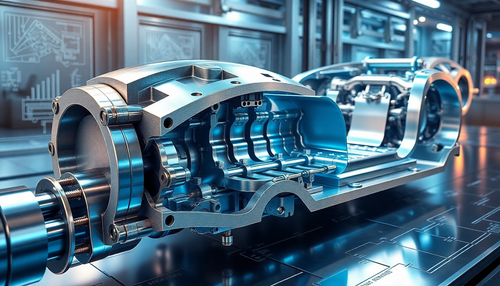

Chassis de Aço Inteligente: A Revolução da Segurança Autônoma

Em um mundo em constante evolução, a indústria automotiva está à beira de uma transformação revolucionária. Com o avanço da tecnologia, os carros autônomos estão se tornando uma realidade cada vez ...

-

Aços Avançados de Alta Resistência (AHSS) Revolucionando a Indústria Automotiva

A indústria automotiva está constantemente em busca de soluções inovadoras que permitam a fabricação de veículos mais leves, seguros e eficientes. Nesse contexto, os Aços Avançados de Alta Resistên...

-

Aço Reciclado impulsiona a Revolução das Motocicletas Elétricas

A indústria de motocicletas está passando por uma transformação revolucionária, com a adoção cada vez maior de veículos elétricos. Essa mudança é impulsionada não apenas pela crescente conscientiza...

-

Aço na Mobilidade Sustentável: Veículos Leves e Eficientes

A indústria automotiva enfrenta um desafio crucial: reduzir as emissões de carbono e melhorar a eficiência energética dos veículos, sem comprometer a segurança e o desempenho. Neste contexto, o aço...

-

Lecar, a nova estrela da indústria automotiva brasileira

A Lecar, uma empresa brasileira que está conquistando seu espaço no setor automotivo, acaba de anunciar planos ambiciosos para se tornar uma das principais fabricantes de veículos no país. Recentem...

-

A FIAT consolida sua liderança global em 2024

A FIAT confirma sua posição como marca líder da Stellantis em volume de vendas, dominando mercados importantes, como Brasil, Itália, Turquia e Argélia, com o Fiat Strada e Panda se destacando entre...

-

Tendências do Mercado Automotivo em 2024: Rumo a uma Mobilidade Mais Sustentável e Conectada

Uma análise de tendências de consumo no mercado automotivo em 2024 destaca a busca por marcas confiáveis, menor depreciação e custos reduzidos de manutenção, enquanto híbridos e elétricos despontam...

-

Revolução da Mobilidade Urbana: Ônibus Autônomos sem Mapas

No campo sonoro da robótica, a inovação constante é essencial para atender às necessidades de um mundo em rápida evolução. Um dos avanços mais fascinantes é a criação de sistemas de transporte públ...

-

Maior fábrica de Nióbio do mundo impulsiona a inovação em Baterias de Carregamento Ultrarrápido

Araxá, em Minas Gerais, é agora o local da maior fábrica de nióbio do mundo especializada em baterias de carregamento ultrarrápido. A unidade tem capacidade para produzir 2.000 toneladas por ano do...

-

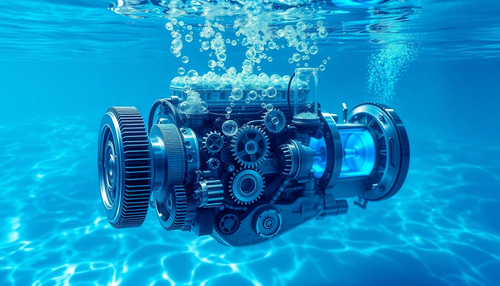

Soluções poliméricas inovadoras apoiam a mineração de Lítio Sustentável

À medida que a demanda global por lítio continua a aumentar, impulsionada pelo aumento de veículos elétricos e tecnologias de energia renovável, os desafios de manutenção enfrentados pelas operaçõe...

-

Bio-Híbrido: Solução eficiente para a indústria automotiva

A chegada do Bio-Híbrido

Batizado de Bio-Híbrido, trata-se de um recurso eficiente, ajuda a economizar combustível e aumenta os preços dos SUVs compactos Pulse e Fastback em apenas R$ 2.000, ou sej...

-

Nissan e Mitsubishi Formam Nova Joint Venture para Mobilidade Autônoma e Elétrica

As gigantes japonesas Nissan e Mitsubishi, que estão ligadas por meio de suas participações na aliança com a Renault, formarão uma nova joint venture para fornecer serviços relacionados à direção a...

-

BID e BID Invest ampliam financiamento verde e climático na América Latina e Caribe

O Banco Interamericano de Desenvolvimento (BID) e seu braço para o setor privado, BID Invest, anunciaram recentemente uma ampliação significativa do foco na sustentabilidade climática e ambiental e...

-

Crescimento impressionante da Indústria Automotiva brasileira em 2024

O ano de 2024 tem sido um período de grande crescimento e otimismo para a indústria automotiva brasileira. Segundo os dados divulgados pela Associação Nacional dos Fabricantes de Veículos Automotor...

-

Toyota e Suzuki unem forças para lançar novo SUV Elétrico em 2025

Em uma movimentação estratégica no mercado automotivo, as gigantes Toyota Motor Co. e Suzuki Motor Corp. anunciaram uma colaboração histórica no segmento de veículos elétricos (EVs). O resultado de...

-

Mercado Global de Veículos Elétricos rumo ao Trilhão de Dólares

O mercado global de veículos elétricos (VEs) está em forte ascensão e deve atingir US$ 1 trilhão em receita até 2028, com um crescimento projetado de 27% nas vendas. Mesmo com obstáculos como infra...

-

Futuro dos Veículos Elétricos e Mobilidade: Desafios e oportunidades no Brasil

No final de 2022, a União Europeia local o acordo "Fit For 55", com o objetivo de encerrar as vendas de carros novos emissores de CO₂ na Europa até 2035. O anúncio fez com que vários montadoras glo...

-

Detectando falhas de baterias de Veículos Elétricos antes que seja tarde demais

As baterias em veículos elétricos podem falhar rapidamente, às vezes pegando fogo sem muito aviso. O Sandia National Laboratories está trabalhando para detectar essas falhas cedo e fornecer tempo d...

-

Bentley atrasa meta de oferecer apenas Veículos Elétricos para 2035

A marca britânica de ultra-luxo, pertencente ao grupo Volkswagen AG, adiou novamente sua meta de oferecer apenas veículos elétricos a bateria (BEVs) em cinco anos, agora para 2035. No entanto, plan...

-

O Primeiro Caminhão Híbrido Conceito do Mercado Nacional

A Volkswagen Caminhões e Ônibus e a Suspensys, uma das empresas de autopeças do Grupo Randon, está desenvolvendo o primeiro caminhão conceito híbrido do mercado nacional. O protótipo foi apresentad...

-

FPT Industrial investe R$ 127 milhões em novas tecnologias de propulsão

A FPT Industrial, marca integrante do Grupo Iveco dedicada ao design, produção e venda de motores, informou que irá investir R$ 127 milhões em pesquisa e desenvolvimento de novas tecnologias de pro...

-

Reciclagem de Baterias de Veículos Elétricos: O Papel de liderança da China

A China talvez esteja em uma posição privilegiada quando se trata de adoção de veículos elétricos (VE), respondendo por mais de 60% das vendas mundiais em 2022. Essa posição dominante a torna um pa...

-

Solução Inovadora para preservar a privacidade na internet dos Veículos

Cientistas afirmam ter desenvolvido uma ferramenta de inteligência artificial para consolidar a privacidade dos veículos e de seus motoristas. Como preservar a privacidade da chamada Internet dos V...

-

Avanço significativo em Baterias de Íons de Lítio: Cátodos ricos em Lítio com Vanádio

À medida que a demanda por veículos elétricos e sistemas de armazenamento de energia aumenta, as baterias de íons de lítio precisam fornecer densidades de energia mais altas a custos mais baixos. E...

-

Vendas de veículos automotores no Brasil atingem novo recorde em 2024

As vendas de veículos automotores no Brasil continuam em alta, com um crescimento expressivo de 16,4% no acumulado de janeiro a outubro de 2024 em comparação ao mesmo período do ano anterior. Segun...

-

Vendas de veículos no Brasil crescem 21,6% em outubro de 2024

A indústria automotiva brasileira registrou um desempenho positivo em outubro de 2024, com um aumento de 21,6% nas vendas de veículos em comparação com o mesmo mês do ano anterior. De acordo com os...

-

Reduzindo os Custos de Teste de Chips Automotivos com Machine Learning

Os chips acabados que vêm da fundição são submetidos a uma bateria de testes. Para aqueles destinados a sistemas críticos em carros, esses testes são particularmente extensos e podem adicionar de 5...

-

A Integração de Veículos Automatizados: Promovendo a Confiança dos Passageiros com Explicações Oportunas

A integração de veículos automatizados promete vários benefícios para a mobilidade urbana, incluindo maior segurança, redução de congestionamento de tráfego e acessibilidade aprimorada. Veículos au...

-

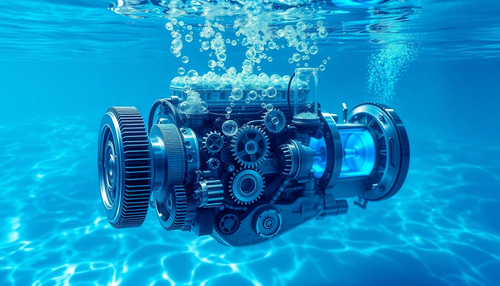

Motor a água da Toyota: Revolução Silenciosa da Mobilidade

A Toyota, uma das líderes do setor automotivo, acaba de apresentar uma inovação que pode redefinir o futuro dos transportes. Um motor movido a água, altamente eficiente e ecológico, promete não só ...

-

Toyota do Brasil anuncia expansão de fábrica em Sorocaba

A Toyota do Brasil acaba de anunciar uma grande expansão de sua fábrica em Sorocaba, no interior de São Paulo. Este investimento de R$ 11 bilhões faz parte do plano de investimentos da empresa para...

-

Combustíveis: Entendendo as Características e Propriedades

Combustíveis são quaisquer materiais que armazenam energia potencial em formas que liberam energia térmica ao queimar em oxigênio. O poder calorífico do combustível é a quantidade total de calor li...

-

Ascensão da BYD: Como a marca Chinesa está desafiando a Tesla

A BYD, marca que começou com a produção de baterias e hoje desafia gigantes globais, está mudando o cenário da indústria automotiva com uma trajetória que exemplifica o poder da inovação e da expan...

-

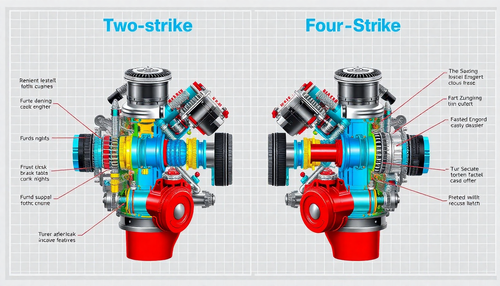

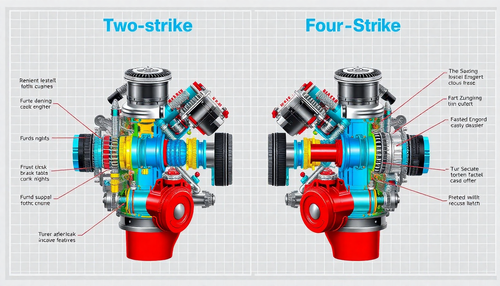

Motores de 2 Tempos vs. 4 Tempos: Entendendo as diferenças

Ao comparar o motor de 2 tempos com o motor de 4 tempos, é essencial entender o que diferencia esses tipos de motor. Cada um tem benefícios, aplicações e características de desempenho exclusivos, t...

-

Ecossistema de Aplicativos: 5 coisas essenciais para se ter dominio

Os ecossistemas de aplicativos estão se expandindo e se tornando mais complexos com o surgimento de aplicativos baseados em IA, esforços de modernização e novas iniciativas. Embora eu não ache que ...

-

Um avanço na ciência dos materiais pode ajudar a entregar uma nova geração de baterias acessíveis

A busca por baterias mais eficientes e acessíveis é um desafio constante na indústria de energia. Recentemente, uma equipe internacional de pesquisadores liderada por químicos da Universidade de Gl...

-

Caracterização de Baterias de Íons de Lítio com Ânodos de Silício usando Espectroscopia de RMN

Pesquisadores do Laboratório Nacional Argonne do Departamento de Energia dos EUA (DOE) desenvolveram e demonstraram um conjunto inovador de métodos para avaliar o envelhecimento a longo prazo em cé...

-

Fiat solidifica liderança no mercado Automotivo brasileiro em 2024

O mês de outubro de 2024 foi marcado por uma expressiva liderança da Fiat no mercado automotivo brasileiro. Com 20,9% de participação e 51.867 unidades emplacadas, a marca consolidou sua posição ta...

-

Carros Elétricos vs. Combustíveis Renováveis: Dilema da Sustentabilidade

Com recorde de vendas em 2024, os carros elétricos são promovidos como solução verde, mas especialistas questionam o impacto ambiental das baterias e a complexidade da reciclagem, abrindo espaço pa...

-

Jeep no mercado brasileiro: Liderança nos principais segmentos de SUVs

A Jeep encerrou o mês de outubro com 12.014 emplacamentos, marcando seu melhor desempenho de vendas nos últimos três meses. Com este resultado, a montadora atinge um total de 99.930 unidades comerc...

-

Waymo e o uso do Gemini na Direção Autônoma

A decisão da Waymo de utilizar o Gemini em seu sistema de direção autônoma é significativa por várias razões. Primeiro, ela representa uma mudança no uso de IA generativa e modelos de linguagem de ...

-

Indústria de Autopeças Brasileira projeta crescimento de 8% em 2024

A indústria de autopeças brasileira está se preparando para um ano de 2024 promissor, com projeções de faturamento revisadas e altas significativas em diversos segmentos. De acordo com o Sindicato ...

-

Stellantis acelera transformação com foco em eletrificação e adaptação aos consumidores

Em 2024, a Stellantis vem solidificando sua posição no mercado automotivo global com uma série de lançamentos estratégicos e foco em tecnologias multienergia. As novas plataformas STLA, desenvolvid...

-

Importância da Estamparia na Indústria Automotiva

Os carros são chamados de "máquinas que mudam o mundo". Como a indústria automobilística tem uma forte correlação industrial, ela é considerada um símbolo importante do nível de desenvolvimento eco...

This is the first family of automotive-grade touchscreen controllers to natively support detection and reporting of capacitive rotary encoders and mechanical switches on the top of a touch panel.

This is the first family of automotive-grade touchscreen controllers to natively support detection and reporting of capacitive rotary encoders and mechanical switches on the top of a touch panel.