A single cell is not enough for some devices. To achieve the desired voltage, cells are connected in series to add cell voltage. To achieve the desired capacity, cells are connected in parallel to obtain high capacity by adding amp hours (Ah). This combination of cells is called a battery.

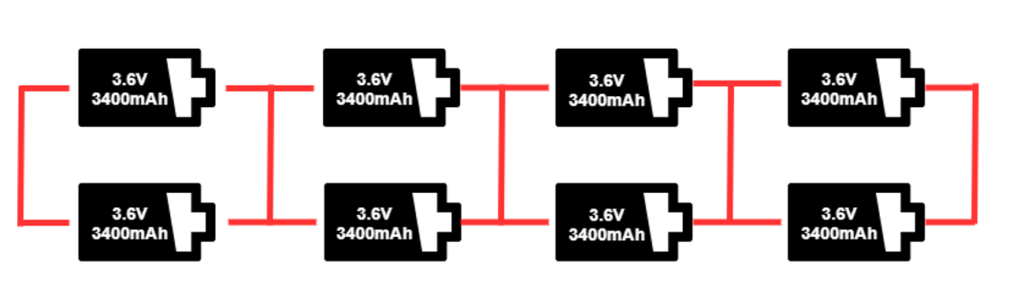

Sometimes batteries are used in both configurations together to obtain the desired voltage and high capacity. This configuration is found in the laptop battery, which has four 3.6V lithium-ion cells connected in series to get 14.4V. Each cell has another cell connected in parallel to get double the 6800mAh capacity.

Laptop battery configuration.

The battery connected in the setup must have the same voltage and capacity, as the weaker cell causes imbalance. In a series configuration, the battery is only as strong as the weakest link in the battery chain, so the higher capacity cell cannot charge more than the weaker cell. The weaker cell also discharges and charges first, which also causes problems like over-discharging and over-charging the device.

Single cell configuration

The single cell configuration is the simplest battery. This setting is available in wall clock, memory backup and wrist clock. All of these devices are low power consumption, so they use a 1.5V alkaline battery. Cell phones and tablets are also available in a single-cell configuration with a 3.6V lithium-ion battery. The image below shows the single-cell configuration of the lithium-ion battery.

As we have seen, the nominal voltage of a single lithium-ion cell is 3.6 V. A nickel-based battery has a nominal voltage of 1.2 V, and an alkaline battery has a nominal voltage of about 1.2 V. 5 V. The other lithium-based battery has a voltage between 3.0 V and 3.9 V. Lithium phosphate has 3.2 V and lithium titanate has 2.4 V. Lithium manganese and other lithium-based systems typically use cell voltages of 3.7V and higher.

Serial configuration

Series configuration is used where the voltage of a single cell is not sufficient. The series configuration is obtained by connecting the positive of one cell to the negative of another cell, as shown in the image below. The four 3.6V lithium-ion cells connected in series will provide 14.4V, and this configuration is called 4S because four cells are connected in series.

The number of cells can vary depending on the voltage of a single cell. A lead-acid battery has a nominal voltage of 2 V, so it takes six cells connected in series to reach 12 V. Six alkaline batteries with a voltage of 1.5 V per cell connected in series will provide 9 V.

The number of cells can vary depending on the voltage of a single cell. A lead-acid battery has a nominal voltage of 2 V, so it takes six cells connected in series to reach 12 V. Six alkaline batteries with a voltage of 1.5 V per cell connected in series will provide 9 V.

If the device needs an odd voltage, for example 10 V, three lithium-ion batteries can be connected in series. But when the device needs 8.5V Li-ion, you need to know the specifications of your device. If it supports 10V, then it can be connected directly; otherwise, a buck or boost is used to reach 8.5V.

If a cell in a series is defective, cell matching is a challenge in an aging pack at the time of cell replacement. The new cell has a greater capacity than the others, which causes an imbalance. This is why batteries are commonly replaced in units.

The BMS (Battery Management Systems) or its controller can determine the faulty battery by measuring the voltage at each point of the battery as shown below in the image. The cell is faulty which is giving 2.8V instead of 3.6V. Due to this, the battery voltage collapses and the device will shut down early with a low battery message. You can fix your battery by replacing this cell.

Parallel configuration

Parallel configuration

Cells are connected in parallel to meet higher current capacity requirements if the device needs a higher current but there is not enough space available for the battery. This device can use parallel configuration to adjust high current capacity in a small space. The configuration of four cells in parallel is called P4, and the three cells connected in a parallel configuration are called P3. The image below shows a P4 configuration. The voltage on the package remains the same, but the current capacity (Ah) is increased.

The cell developing high resistance or opening is less critical in a parallel circuit than in a series configuration, but the failing cell will reduce the total current capacity. On the other hand, a short circuit is more serious because the faulty cell drains energy from the other cells and causes a fire. The short occurs due to reverse bias or dendrite growth. The large cell includes a fuse to disconnect the failed cell when it shorts out. In the image below, the third cell in the blue box has failed and the capacity has been reduced to 1500 mAh. Does not affect voltage, but reduces total capacity.

The cell developing high resistance or opening is less critical in a parallel circuit than in a series configuration, but the failing cell will reduce the total current capacity. On the other hand, a short circuit is more serious because the faulty cell drains energy from the other cells and causes a fire. The short occurs due to reverse bias or dendrite growth. The large cell includes a fuse to disconnect the failed cell when it shorts out. In the image below, the third cell in the blue box has failed and the capacity has been reduced to 1500 mAh. Does not affect voltage, but reduces total capacity.

Series-parallel configuration

Series-parallel configuration

In this configuration, cells are connected in series and parallel. The series-parallel configuration can provide the desired voltage and capacity in the smallest possible size. You can see two 3.6V 3400mAh cells connected in parallel in the image below, which doubles the current capacity from 3400 mAh to 6800 mAh. Since these parallel packs are connected in series, the voltage also doubles from 3.6 V to 7.2 V. The total power of this pack is now 48.96 Wh. This configuration is called 2SP2. If the configuration consists of eight cells with the 4SP2 configuration, two cells are in parallel and four packages of this parallel combination are connected in series. The total power produced by this pack is 97.92 Wh.

Battery protection

Battery protection

IEC 62133 harmonized the safety requirements for nickel and lithium-based batteries and cells for portable applications. Lithium-ion batteries are the most dangerous batteries in their category because the battery chemistry contains explosive material. Battery protection is necessary to prevent any damage due to high current discharge, overcharge, temperature rise, etc. Protection may be built into the battery structure or external protection circuitry may be used to disconnect the battery.

Integrated battery protection

Some batteries come with safety features inside the battery structure. The image below illustrates the safety feature of 18650 Li-ion cells. PTC (positive thermal coefficient) is the resistance that is very low during normal temperature. But when the temperature exceeds the critical condition, its resistance increases to reduce the current flow. PTC comes under normal resistance when the temperature drops below the critical range.

The CID (current interrupting device) is a fuse-type device that permanently cuts the circuit when the cell's pressure, temperature, or voltage range exceeds its limits. If the internal pressure increases by about 1000 kPa, the upper disc disconnects from the metal foil and disconnects the current flow. There is an opening at the top to release the gas and can be closed again.

Integrated protection.FE

Battery protection circuit

Some 18650 lithium-ion batteries come with a protection circuit. The basic function of the protection circuit is to protect batteries against overvoltage, undervoltage, overcurrent and over and undertemperature. This is part of the BMS. The BMS monitors the battery status for safer operations and sends the signal to the protection circuit in case of battery failure. When the protection circuit is connected to the positive terminal of the battery, it is called high side protection. When it is connected to the negative side of the battery, it is called negative side protection.

The block diagram of the protection circuit is given below. This is a high side protection circuit. The battery configuration is S4 (four in series) and a fuse is connected to the positive side of the battery to shut down the battery when the current exceeds the limits. There is BMS monitoring of each cell voltage for balancing and fault detection. The current sensing unit will detect the load and discharge the current it sends to the BMS. If any voltage or current reading exceeds the limits, the BMS sends the signal to the protection circuit that turns off the cell with charger or load.

Protection circuit in batteries.

There are some pre-made circuits available in the market that are fixed to your voltage or current needs. Just know the current and voltage specifications of battery protection modules, or you can also build your own with commercially available MOSFETs and BMS.

References

- /learn/article/safety_circuits_for_modern_batteries