Plug in

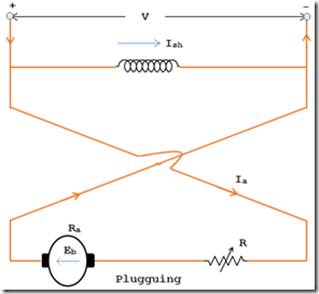

The following figure shows how to connect a DC shunt motor. In this technique, the motor tends to rotate in the opposite direction, reversing the armature connection, creating the essential braking effect. When the motor returns to the starting position, the power connection must be disconnected, otherwise it will rotate continuously in the opposite direction.

Although the armature connections are reversed, the connections in the field windings remain the same. Therefore, the armature current reverses. When the motor is running at normal speed, the back emf opposes the applied voltage. During connection to the armature, the back emf is inverted and the applied voltage acts in the same direction throughout the circuit. Thus, a voltage equal to V+Eb is applied to the armature circuit. Since Eb is equal to the source voltage, the voltage applied across the armature is 2 V. By changing the armature connections, an adjustable resistor R is inserted into the circuit to limit the current to a safe value.

Now we see how braking torque depends on engine speed.

From the figure above (clogging)

Armature current I A = (V + E b ) / (R=R A )

EU A = (F/R+R A ) + (K 1 NΦ/R+R A )

∵E b ∝ NΦ

Braking torque T b =K 2 I A Φ

T b =K 2 Φ {(V/R+R A ) + (K 1 N Φ /R+R A )}

∴T b =K 3 NΦ + K 4 No 2

In a DC shunt motor, Φ is constant.

Hence the braking torque ∴ TB = K5 + K6N

Therefore, braking torque decreases as engine speed decreases. Even if the engine speed is reduced to zero, a certain braking torque (T b =K 5 )

Regenerative braking

The figure above shows the regenerative braking of a DC shunt motor. With this method, the engine works like a generator. The motor converts kinetic energy into electrical energy and returns it to the power source. Two methods can be used for regenerative braking of a shunt DC motor.

-

Armature reaction in DC motor

In the first method, the field windings are separated from the source and the field current is increased by exciting a separate source. Therefore, the induced electromotive force exceeds the source voltage and the machine supplies energy to the source. Therefore, the braking torque is applied up to the engine speed until the induced electromotive force and the supply voltage are equal. Once the machine speed drops, it is no longer possible to maintain the induced electromotive force at a value higher than the supply voltage. Therefore, this technology is only used in a limited speed range.

Another technique does not change the excitation of the field, but instead causes the load to cause the motor to run above rated speed (i.e., reducing the load on a hoist). This causes the induced electromotive force E to be greater than the source voltage. Therefore, the current in the armature reverses and the current in the shunt field remains unchanged. Thus, the torque reverses and the motor speed decreases until the induced electromotive force E becomes less than the supply voltage.