Various methods and devices are used to control electric motors. One such device is the three-point starter, an important component in electrical engineering. In this comprehensive guide, you will learn the ins and outs of using a three-point starter to control your engine. Whether you are an experienced electrical engineer or a beginner looking to understand this important device, this article will provide you with the insights you need.

Understand the basics of a 3-point starter

Before we delve into how to use a three-point starter, let's look at the basics and their importance in engine control.

What is a 3 point starter?

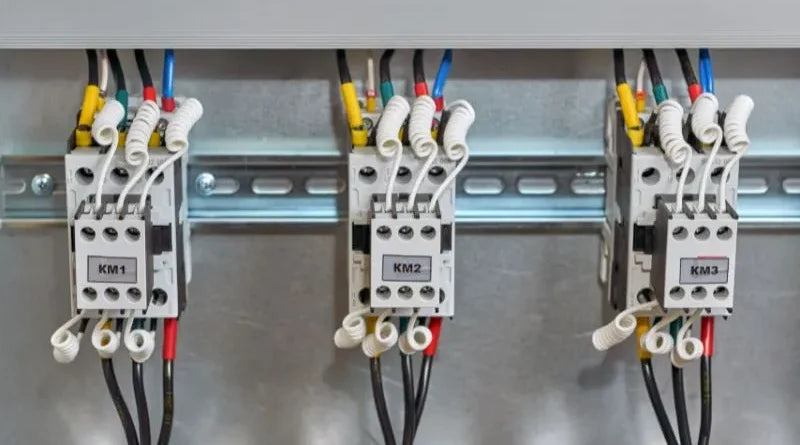

A 3-point starter is an electrical device primarily used to control the speed and direction of DC motors. It is often used in applications that require precise control of engine speed and torque. The name “3 points” refers to the three main terminals connected to the starter: anchor terminal, field terminal and power terminal.

How does a 3 point starter work?

The 3-point starter controls the flow of current to the armature and field windings of a DC motor. It consists of a series of resistors and contacts that are adjusted manually or automatically to control current. By changing the resistance in the circuit, the starter can effectively control the speed and direction of the motor.

Why is a 3 point starter necessary?

A three-point starter performs several important tasks in engine control:

- Speed control: One of the main functions of a three-point starter is to regulate the speed of a DC motor. By varying the resistance in the circuit, the motor can be slowed down or sped up as needed.

- Directional control: The 3-point starter allows you to reverse the direction of engine rotation. This is important in applications where a motor needs to run clockwise and counterclockwise.

- Surge Protection: In the event of overload or excessive current draw, the 3-point starter can protect the motor from damage by tripping and interrupting the circuit.

How to Use a 3-Point Starter to Control the Engine

Now that we've established the importance of a three-point starter, let's now look at the steps to using it effectively in engine control.

Step 1: Inspection and Safety Precautions

Before using a three-point match, it is important to carefully inspect the device. Look for signs of wear, loose connections or damaged components. Make sure all safety measures, including proper grounding and circuit protection devices, are in place.

Step 2: Connect the power supply

Connect the three-point starter power connector to the power source. This provides power to the circuit. Be sure to follow the manufacturer's guidelines regarding voltage and resistance ratings.

Step 3: Anchor and Field Clamps

Connect the armature terminal to the DC motor armature winding and the field terminal to the field winding. These connections are absolutely necessary for the engine to function.

Step 4: Adjust the resistance

The key to controlling motor speed is to adjust the resistance. Most 3-point starters have a rheostat or series of resistors that can be adjusted manually. Start with a high resistance setting and gradually reduce it to increase engine speed.

Step 5: Start and Stop

To start the engine, gradually reduce the resistance until the engine starts to rotate. To stop it, increase the resistance back to a high level. With this simple adjustment you can effectively control the engine speed.

Step 6: Directional Control

To change the direction of rotation of the motor, reverse the polarity of the armature or field winding. This is usually done using a reversing switch or relay connected to the three-point starter.

Additional Considerations for First-Time 3-Point Users

Although we have covered the basics of using a three-point starter to control the motor, some additional considerations may improve your understanding and competence in using this device.

maintenance and inspection

Regular maintenance and inspection are essential to the reliable operation of a 3-point starter and the motors it controls. Here are some maintenance tips:

- Check for loose connections and tighten if necessary.

- Check resistors for signs of overheating or damage and replace if necessary.

- Lubricate all moving parts to prevent friction and wear.

- Keep the starter and the surrounding area clean and free from dust and dirt.

Upgrade to modern engine control solutions

3-point starters have been a reliable choice for many years, but modern motor control solutions offer several advantages:

- Energy efficiency: Electronic motor controllers such as VFDs can significantly improve energy efficiency by matching motor speed to load, reducing energy consumption and operating costs.

- Precise Control: VFDs control motor speed and torque, allowing for smoother, more precise operation.

- Advanced Features: Modern controllers often have advanced features such as fault detection, remote monitoring, and data logging that can improve maintenance and troubleshooting.

Troubleshooting common problems

Even with proper maintenance, problems can occasionally occur. Here are some common problems you may encounter when using a 3-point game:

- Engine won't start: If the engine won't start, check for loose connections, damaged resistors, or an open circuit. Make sure the supply voltage meets the motor specifications.

- Motor overheating: Overheating can be caused by too much current or insufficient ventilation. Check to see if the airflow is blocked, if the brushes are worn, or if the motor is overloaded.

- Inconsistent speed control: If speed control is not consistent, check the rheostat or resistors for damage or wear. Clean the contacts to ensure a reliable connection.

- Safety Concerns: When using a 3-point match, safety is always the number one priority. Use caution when adjusting and make sure all interlocks and safety guards are in place and functioning properly.

Conclusion

In summary, understanding how to use a three-point starter to control motors is essential for anyone working with DC motors. These devices have been a reliable choice for motor control for many years, providing speed and direction control as well as overload protection. By following the steps outlined in this guide and considering maintenance and modern alternatives, you can ensure the efficient and safe operation of your engine control systems.

While 3-point starters are useful in many applications, modern motor control solutions such as VFDs can improve the performance, energy efficiency and advanced features of your motor-driven systems. Stay up to date on the latest advances in motor control technology to make informed decisions for your specific needs.

Common questions

1. Can I use a 3-point starter with any engine?

Although 3-point starters are primarily designed for DC motors, they are unsuitable for AC motors. AC motors require different starters depending on the configuration, e.g. B. Direct start (DOL) or star-delta start.

2. What safety precautions should I take when using a 3-point game?

Safety is the top priority when working with electrical devices. Always use appropriate personal protective equipment (PPE), follow the manufacturer's instructions and ensure adequate grounding and circuit protection to avoid electrical accidents.

3. Are there modern alternatives to 3-point games?

As technology advances, electronic motor controllers such as variable frequency drives (VFDs) are becoming increasingly popular for motor control. They offer precise speed control, energy efficiency and advanced features compared to traditional 3-point starters.