An electronic speed controller (ESC) is a vital component of a First Person View (FPV) drone. A drone's propulsion system is built from three main components:

- The flight controller

- The electronic speed controller (ESC)

- Drone engines

The flight controller receives signals from the radio transmitter and sends signals to the ESC. Thus, the ESC controls the engine rotation speed, maneuvering the drone in the sky. Because each drone's motor spins at a slightly different speed, each requires an ESC – which works similarly to a vehicle's gearbox. It controls the rotation speed based on timed signals.

A drone uses brushed or brushless DC motors. Brushed DC motors are cheaper and often used in toys or mini drones. Commercial and consumer drones use brushless motors, which are more expensive but also more effective. ESCs of different types are used with both motors.

The newest generation of electronic speed controllers is advanced and offers numerous features. It is recommended to purchase a combination of flight controllers and ESCs to avoid cross-vendor compatibility. The FC-ESC combo is an option, and the compatible ESC and flight controller can be purchased separately. All components of a drone's propulsion system are tightly coupled. That's why it's important to review the specifications of EFCs before purchasing one.

The newest generation of electronic speed controllers is advanced and offers numerous features. It is recommended to purchase a combination of flight controllers and ESCs to avoid cross-vendor compatibility. The FC-ESC combo is an option, and the compatible ESC and flight controller can be purchased separately. All components of a drone's propulsion system are tightly coupled. That's why it's important to review the specifications of EFCs before purchasing one.

In this article, we will discuss the main factors to consider when choosing an electronic speed controller for your DIY FPV drone.

What exactly is an electronic speed controller?

An electronic speed controller controls the speed of a drone's motors based on acceleration signals from the flight controller. An ESC connects the motors to the flight controller and battery. The flight controller cannot directly control the drone's motors, so the ESC operates as interface hardware between the two. It is also responsible for converting the DC power from the LiPo battery into three-phase AC power for the drone's motors.

The ESC interfaces with the motor via three wires. The wiring determines the direction of rotation of the motor. The amount of current supplied to the motor and the speed of rotation depend on the acceleration signal from the flight controller.

The ESC circuitry consists of a microcontroller, MOSFETs, gate drivers, a low dropout regulator, and filtering capacitors. It may also have a current sensor and LEDs on the circuit board. It may have a battery kill circuit (BEC), but not always.

The types of ESC

As mentioned, drones are built with brushed or brushless motors. However, the electronic speed controllers for these engines are different. ESCs for brushed motors are commonly used in RC vehicles. ESCs for brushless motors are lightweight, providing high performance and control. All commercial drones use brushless motors.

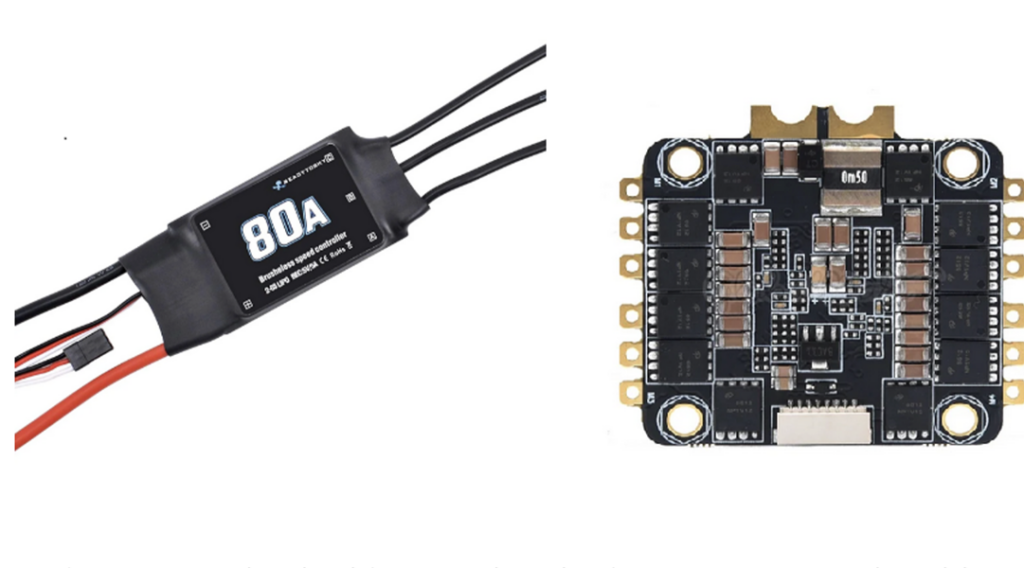

ESCs are also available in two configurations:

- Single ESCs – autonomous modules that control a single drone motor

- 4-in-1 CES – comprises four unique ESCs integrated into a single board

Single ESCs are low-cost ESC circuit boards that can be mounted on the arms of a drone, offering better airflow and natural cooling. They are easy to install and replace if damaged.

The LiPo battery powers the ESC through a power distribution board (PDB) or All-in-One (AiO) flight controller, which has a built-in PDB. Each ESC connects to the flight controller via a different wire harness, and this wiring (with solder) adds weight to the drone. This wiring in the drone structure is the main disadvantage of single ESCs.

Furthermore, when installing individual ESCs, the central mass of the drone must be adjusted accordingly.

4-in-1 ESCs are designed for use in quadcopters. These modules come in the same size as the flight controller and are based on the mounting pattern of standard drone structures. For example, the sizes of 4-in-1 ESCs include 16x16mm, 20x20mm, 30x30mm, etc.

A 4-in-1 ESC is mounted just below the flight controller, connected via a single harness. Using a 4-in-1 ESC is convenient and minimizes soldering and wiring. Additionally, because it is mounted in the center of the drone, just below the flight controller, there is no need to adjust the drone's center of mass.

However, these ESCs lack modularity. The entire board must be replaced if a single ESC is damaged in a 4-in-1 ESC, although they are generally reliable. Larger ESCs are the most durable as they have larger MOSFETs integrated.

If you are building a quadcopter, a 4-in-1 ESC is the most convenient option. Single ESCs are more affordable and offer modularity and low risk. If you are building a different drone, such as a three-rotor drone, hexacopter, octocopter, or other design, single ESCs are the only option.

Why use ESC?

A flight controller cannot directly control the drone's motors, regardless of whether they are brushed or brushless. One reason is that the flight controller is a microcontroller board that operates at low voltage and current, while the drone's motors operate at high current. Secondly, drone motors are inherently unstable. The speed of the motors simply cannot be controlled without a dedicated circuit like an ESC.

The aerodynamics of a multicopter are more complex compared to that of a helicopter. In a helicopter, only one rotor generates thrust for flight, and there is a tail rotor to counterbalance the torque generated by the main rotor. In a multicopter, each engine generates its own thrust, which must be controlled to ensure stable flight.

The flight controller has a built-in gyroscope sensor that monitors the drone's orientation and direction. The flight controller generates timed signals to all rotors according to feedback from the gyroscope sensor. This ensures that the multicopter maintains a stable orientation during flight.

How an ESC works on FPV drones

An ESC for brushed and brushless motors is based on the same principle. The ESC draws power from the LiPo battery and receives a control signal from the flight controller. The control signal is a pulse width modulated (PWM) wave. The amount of current supplied to the motor is proportional to the width of the PWM signal.

Thus, the engine rotates at a higher speed when the flight controller sends a wider control signal to the ESC, and vice versa. The flight controller's control signal is determined based on feedback from the flight controller's orientation and heading sensors and pilot input from the remote transmitter.

The variable speed of the rotors is controlled so that the drone flies in the instructed direction and altitude, maintaining its orientation and aerial stability.

Main specifications of an ESC

The components that make up a drone's propulsion system are tightly coupled and critical. The motors, flight controller, ESC and LiPo battery must be compatible. Let's assume you've already purchased the motors, a compatible battery, and a flight controller for your DIY drone. Now it's time to choose the ESCs. Consider these specifications first.

Current rating : This is the amount of current the ESC can safely handle and the first thing to consider when selecting an electronic speed controller – and it can be difficult to determine. The desired current rating depends on the drone's motor and propeller. The motor has a rated current. Most BLDC motors have a peak starting current three times or more than the rated current. The larger the size of the motor and its KV rating, the greater the current. Larger or heavier propellers also increase the current drawn by the motors. When a motor rotates, if the current drawn by it is greater than what the ESC can handle, the ESC will overheat and eventually burn out.

ESCs have two current ratings, continuous and intermittent. The current rating indicated on the ESC sticker is the direct current rating. It is the maximum continuous current that an ESC can normally handle. The breakdown current rating is the maximum current that an ESC can tolerate for a few seconds. If the current drawn by the motor exceeds the breakdown current rating and persists for longer (>10 seconds), the ESC will burn out. The breaking current rating is always higher than the direct current rating.

Typical direct current ratings for an ESC are 6A, 10A, 20A, 30A, and 35A. ESC 6A and 10A are suitable for toys and mini drones with smaller and lighter propellers. Generally, these drones are powered by two- or three-cell LiPo batteries. 30A or 35A ESCs are suitable for larger drones with five-inch propellers or powered by five- or six-cell LiPo batteries.

The 30A and 35A ESCs are similar in weight, but the 35A ESC offers better reliability and durability. As a general rule, the amperage of ESCs should be at least 10~15% greater than the maximum current of the drone's motor at full throttle. If the motor rating is 20A at full throttle, the ESC direct current rating must be at least 25A.

Many ESCs have a built-in temperature sensor to prevent overheating and prevent the drone from flying close to objects with high thermal conductivity.

Drone motors rarely, if ever, draw the maximum rated current. The maximum current normally consumed always remains 20~30% lower than the maximum rated current. If the maximum current drawn at full throttle by a motor is 20A in ground conditions, it will normally draw a maximum current of 15~16A during flight.

There are two reasons for this. During a flight, drone engines rarely operate at full throttle. The rotation speed varies in seconds to maintain orientation and follow the instructed direction. Secondly, the motors and ESC experience a cooling effect due to airflow during flight.

It is important that the current ESC rating is not unnecessarily higher than the drone's requirements. If a drone only needs 20A ESC, adding a 35A ESC will not harm the operation, but it will add extra weight and size to the drone.

Input Voltage Rating : The maximum voltage rating of an ESC is also important. Although some ESCs are rated for 3S-4S LiPo batteries, others can support 6S LiPo batteries. If the battery voltage is higher than the maximum ESC voltage, both the ESC and the motor may be damaged. If a motor is powered by a high voltage battery, the current consumed to provide the same power is reduced.

Therefore, if a high voltage ESC is selected, the overall power will be increased. A high voltage drone can fly faster than a low voltage drone. Battery voltage peaks are always higher than the nominal voltage. This is why many manufacturers prefer 6S ESC due to the higher voltage tolerance.

Weight and size : Typically, the higher the current ESC rating, the heavier the drone – and vice versa. The lighter the drone, the better… but there are tradeoffs. Lower current ESCs are lighter, but generally offer lower performance and less heat dissipation (which can lead to overheating).

A high current ESC offers better performance and cooling, but will be larger in size and weight. Typically, individual ESCs weigh about 4 to 6 grams, and a 4-in-1 ESC weighs about 12 to 15 grams. If the structure of a drone has thin or short arms, the size of a single ESC should not exceed 1~2mm of the arm dimensions. For quadcopters, a 4-in-1 ESC is the ideal option, available in ratings from 6A to 35A and fits easily under the flight controller regardless of size.

ESC Firmware : Firmware determines the performance of an ESC. It also provides information about supported ESC protocols and configuration interfaces.

Some popular ESC firmware include BLHeli_S ESC, BLHeli ESC, BLHeli_32, KISS, and SimonK ESC.

- SimonK is an older open source ESC firmware that is now outdated. So, it is better to avoid it.

- BLHeli and BLHeli_S are open source ESC firmware. BLHeli is outdated but still used by some ESCs. BLHeli_S is a second generation BLHeli from BusyBee Processors. It comes with PWM hardware for smooth motor control and supports 1-2ms input signals with Oneshot125, Oneshot42 and Multishot.

- BLHeli_32 is a third generation BLHeli with closed source code, requiring license fee. This is based on a 32-bit microcontroller that provides greater processing power, lower latency, and higher refresh rates for input signals.

- KISS is a closed source ESC firmware that only runs on KISS ESCs.

ESC protocols : They are similar to a computer's operating system. Protocols determine how an ESC and a flight controller communicate. They also affect the performance and stability of the drone.

The most popular ESC protocols include Standard PWM, Oneshot125, Oneshot42, Multishot, Dshot, and Proshot. Proshot is the newer ESC protocol, while standard PWM is the older one. The ESC protocol determines the language and rules in which the ESC and flight controller will communicate. It also determines the speed and frequency of communication between the two.

Standard PWM takes 1000~2000 nodes to communicate a data packet, Oneshot125 takes 125~250 nodes, Oneshot42 takes 42~84 nodes, Multishot takes 5~25 nodes, and Dshot takes 13.4~106.8 nodes. Multishot is by far the fastest ESC protocol.

ESC Processor : There are three main families of processors (microcontrollers) that are used in ESC multiplexers: 8-bit ATMEL, 8-bit SILAB, and 32-bit ARM Cortex controllers. ATMEL's first 8-bit controllers were commonly used and compatible with SimonK and BEHeli. Eventually they were surpassed by SILAB's 8-bit controllers, which are only compatible with BELHeli and BLHeli_S. More recently, the 32-bit ARM Cortex controller is commonly used and supports BHeli_32.

Single or 4-in-1 ESC : A single or 4-in-1 ESC can be used in quadcopter construction. But it is cleaner and more convenient to use 4 in 1 ESC.

The 4-in-1 offers clean wiring, centralized weight, and easy installation, and often comes with built-in voltage regulators that can be used for power distribution. However, if one of the 4-in-1's ESCs is damaged, the entire board must be replaced. Individual ESCs maintain the modular design and are more affordable. When assembling individual ESCs, expect more wiring and adjusting the center of mass. For drones other than quadcopters, single ESCs are more suitable.

With or without BEC : BEC stands for battery elimination circuit. An ESC with BEC can power other drone components such as the RF receiver, servos, flight controller and other 5V components. This eliminates the need for extra batteries in the drone and reduces weight. Nowadays, most flight controllers come with a separate power module, enough to power the RF receiver, rudder, and flight controller. In these cases, a BEC in the ESC is not necessary.

There are two types of BEC in ESCs, linear and switched. A linear BEC is cheaper but is only 25% energy efficient. Switched BECs are more expensive but provide 85% energy efficiency. Therefore, it is worth checking whether the BEC included in an ESC is linear or switched. It is also important to check the current BEC rating. It must be greater than the total current consumption of all receivers and servos. For smaller drones, 1.5~2A BEC is sufficient. For medium-sized drones, the 3A BEC is suitable. Large drones need a BEC 5A.

Battery Limitations : If a smaller battery like 3S-4S is selected for a drone, it may discharge prematurely due to internal resistance. The voltage may drop to the discharge limit as more current is drawn from the battery. The battery may also discharge before reaching the maximum ESC current. Therefore, the size of the LiPo battery may limit the flight time and maximum altitude the drone can fly. For longer flight time, a large battery (such as 6S) is preferred – and an ESC with a higher current rating should then be selected.

Responsiveness : Today, many ESCs feature active braking support that improves the responsiveness of the drone. An ESC with dedicated transistors or gate drivers (the ideal choice) typically has better responsiveness. It must also include PWM hardware.

ESC Thrust : The thrust produced by a quality ESC is generally 20 to 30% greater than a less expensive or effective one. The thrust produced in the motors mainly depends on the ESC. Other factors that can affect thrust production in engines include:

- The quality of solder joints

- ESC heat sink efficiency

- The quality of the drone

It is recommended to buy ESC from reputed manufacturers rather than looking for cheaper alternatives.

Capacitors : One of the last things to check is the low ESR capacitors on the ESC power distribution board. These capacitors play an essential role in protecting drone components from voltage spikes. Capacitors also help cancel electronic noise in FPV video signals.

How to choose an ESC?

First, determine the motor and LiPo battery settings for your drone. Then decide whether a single or 4-in-1 ESC is ideal. Both types of ESCs have different advantages and disadvantages. Then you can select ESCs from reputable manufacturers based on current and voltage ratings. This will automatically determine the size and weight of your ESC, which you must ensure is compatible with your drone's design.

Finally, you can select an ESC based on the processor, firmware, and supported protocols. These factors are crucial in determining ESC costs. If the flight controller has a separate power module, you should look for an ESC with BEC. An ESC with switched BEC will be more expensive but more energy efficient. Choosing an integrated processor, firmware, ESC and BEC protocol will depend on the expected performance, quality and longevity of the drone, as well as your budget.