The battery stores electrical energy in the form of chemical energy and the chemical energy again capable of being converted into electrical energy. The conversion of chemical energy into electrical energy is called discharge. The chemical reaction during discharge causes electrons to flow through the external load connected at the terminals, which causes current to flow in the reverse direction of electron flow.

Some batteries are capable of returning these electrons to the same electron by applying reverse current. This process is called charging. Batteries capable of recovering electrons at the same electrode are called rechargeable and if they are not capable of doing so, they are called non-rechargeable.

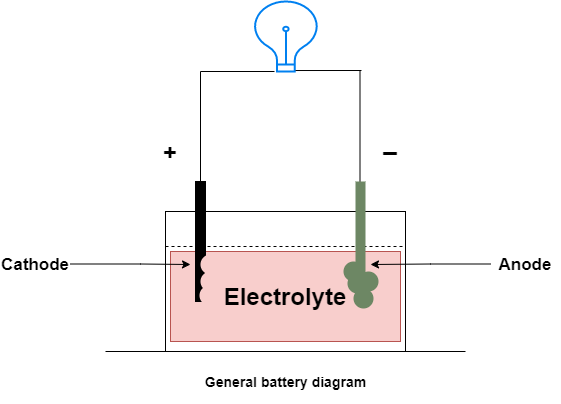

In a battery, the electrode where reduction occurs is called the cathode and where oxidation occurs is called the anode.

There are three types of batteries on the market that are commonly used as rechargeable batteries.

- Lead-acid batteries

- Ni-Cd Batteries

- Ni-MH Batteries

- Lithium-Ion Batteries

Lead-acid batteries

Firstly, the lead-acid battery was invented in 1859 by French physicist Gaston Plante. is a negative electrode (anode) made of spongy or porous lead. The positive electrode (cathode) consists of lead oxide. The anode and cathode electrodes are immersed in an electrolyte solution of sulfuric acid and water (dilute sulfuric acid).

Lead-acid batteries

The chemically permeable membrane separates the two electrodes which prevents short circuits. This membrane also prevents short circuits through the electrolyte.

The lead-acid battery has a nominal voltage of about 2 V, which can vary from 1.8 V on charge with full discharge to 2.40 V on open circuit with full charge. The charging voltage calculation can be done with a voltage of 2.40v/cell. 12V lead acid battery can be made from 6 cells connected in series. The current capacity depends entirely on the manufacturer and size, and can vary from approximately 1Ah to almost 150Ah. For example, 12V with 4Ah or more can be used for vehicle ignition, 12V with 150Ah battery can be used for an inverter.

Discharge of lead-acid batteries

When the battery is connected to a load, the battery starts to discharge. Sulfuric acid (H2SO4) splits into two parts hydrogen (2H ++ ) ions and sulfate ions (SO 4 – ). The hydrogen ion takes an electron from the positive electron and the sulfate ions give an electron to the negative plate. This electron inequality causes the current flow in the external load to balance the electrode inequality.

Lead-acid battery discharge

Reaction at the negative electrode

Pb + HSO 4 – ———-> PbSO 4 +H + + 2e –

Reaction at the positive electrode

PbO 2 + HSO 4 – + 3H + + 2e – ———-> PbSO 4 + 2H 2 Ó

General reaction

Lead + PbO 2 + 2H 2 SO 4 ———-> 2PbSO 4 + 2H 2 Ó

The discharge of the lead-acid battery causes the formation of lead sulfate (PbSO 4 ) crystals on both the positive electrode (cathode) and the negative electrode (anode) and release electrons due to the change in the valence charge of the lead. This formation of lead sulfate uses sulfuric acid sulfate, which is a battery electrolyte. This makes the sulfuric acid less concentrated at full discharge, both electrodes being covered with lead sulphate and water, there is no sulfuric acid around the electrode. The electrode is completely covered with the same material at full discharge. The material is lead sulfate, so there is no chemical potential or voltage between the two electrodes. In practice, there is a cut-off voltage to stop the discharge, long before this point.

Let's find out the discharge rate of lead-acid battery generally specified for 8, 10 or 20 hours, which is C/8, C/10, C/20. if you find battery ratings 12v 200Ah/10h or C/10.

The discharge rate is C/10 = 200 Ah / 10 h = 20A

C/10m cuts voltage after a specific time, here 10 hours for C/10.

Charging lead-acid batteries

Charging begins when the charger is connected to the positive and negative terminals. the lead-acid battery converts the lead sulfate (PbSO 4 ) at the negative electrode to lead (Pb) and at the positive terminal, the reaction converts the lead sulfate (PbSO 4 ) to lead oxide. Chemical reactions are reversed from the discharge process

Lead-acid battery charging

Reaction at the positive electrode

PbSO 4 + 2H 2 O ———-> PbO 2 + HSO 4 – + 3H + + 2e –

Reaction at the negative electrode

PbSO 4 + E + + 2e – ———-> Pb + HSO 4 –

General Reaction

2PbSO 4 + 2H 2 O ———-> Pb + PbO 2 + 2H 2 SO 4

The charging current electrolyzes the water in the electrolyte and both hydrogen and oxygen are produced in this process called “gasification” of the battery. This gasification raises several problems in the battery. This is unsafe due to the explosive nature of the hydrogen produced. This also reduces water in the battery, which can be replaced manually, but adds a maintenance factor. Gassing can cause shadowing of the active material in the electrolyte, which permanently reduces battery capacity, so the battery should not regularly charge above the voltage that causes gassing. Gasification voltage can be changed with charge rate

There are several methods for charging lead-acid batteries. But we must use the best method to reduce the possibility of gas formation, to obtain maximum battery life and capacity. The list of billing methods is provided below.

- Constant Voltage:- As its name, this method will provide constant voltage until the current drawn by the battery reaches zero. It takes a long time

- Constant Current:- As name this method will provide constant current until the voltage reaches the set gassing voltage. It also takes a lot of time.

- Multi-step constant current: – In this method, the charging current is constant when the voltage reaches the gassing voltage and the current starts to be reduced in steps to keep the voltage below the gassing voltage. This charger is complicated to build.

- Modified Constant Voltage Current: – In this method, the battery is charged in three stages. The first stage is the constant current stage, in this current applied to the battery until the voltage reaches its set gassing voltage. In the second stage, the voltage is constant until the current decreases by about 0.1C20 (also known as C20/10). The voltage will be reduced to float voltage (generally 2.25v to 2.27v) to keep the battery charged.

The charging current and gassing voltage can be found on the battery label, as you can see in the picture, there are two modes to choose the charging voltage and current: standby use and cyclic use. Cyclic use is the use of a battery where there is a need to charge and discharge quickly. Standby use is where the battery is already charged and is used when needed. 0.1C means multiplying 0.1 by the total battery capacity. If you have a 40Ah battery, it means 0.1C is 0.1 x 40 = 4A. Same for 0.25C = 0.25 x 40 = 10A.

Lead Acid Battery Instructions

The life cycle of lead-acid batteries

The life cycle of a lead-acid battery depends on several factors. Generally, we say its charge/discharge cycle is around 200 to 300 cycles for shallow cycle batteries, but this number can increase or decrease. The life cycle of this battery depends on three factors: depth of discharge, correct charging cycle and temperature. Deep cycle battery can maintain a cycle life of about 1000, but what are pale cycle and deep cycle? , you can find it below.

-

Depth of Discharge- Depth of Discharge (DOD) means how much your battery is discharged. Let's assume you have a 100Ah battery, you have discharged it for 20 minutes to 50A, then the depth of discharge is given below.

Secret time in hours = 20/60

Calculate discharge time = 50 x 20/60 = 16.7 A

Discharge depth = (discharge/capacity) x 100 = (16.7/100) x 100 = 16.7%

There are two types of battery according to DOD, the battery which has DOD capacity of more than 50% is called Deep Cycle Battery, and battery which has been cut off before 50% of DOD is called Shallow Cycle Battery . Deep cycle battery is able to maintain a cycle life of about 1000 even if the depth of discharge is more than 50%, but shallow cycle battery can increase its cycle life as below graph.

Relationship between battery capacity, depth of discharge and surface cycle battery life

- Charging: If charging is not correct, it will cause overcharging or undercharging, which also reduces the battery capacity.

- Temperature: cycle life is also affected by temperature, battery capacity is reduced in low temperature operation, high temperature operation increases the aging rate of the battery.

Ni-Cd Batteries

Firstly, the Ni-Cd battery was invented in 1899 by Waldermar Jungner. its positive electrode (cathode) made of nickel oxide hydroxide (NiO (OH)) and a negative electrode (anode) made of metallic cadmium (Cd). The electrolyte used is 30% potassium hydroxide (KOH) in distilled water. The electrolyte level is maintained just above the top of the electrode. There are no appreciable changes that occur in the electrolyte during charging and discharging.

(Ni-Cd battery)

This battery has a discharge/charge cycle of around 2,000 cycles. Its nominal voltage is 1.2 V per cell and its fully charged voltage is 1.55 V. It is fully discharged when the voltage drops to 1.1 V. The voltage can be increased by connecting cells in series. The manufacturer defines the battery capacity, normally the available AA battery is close to 1000mAh.

Discharging Ni-Cd batteries

The battery starts to discharge when the load is connected to the terminals. Potassium hydroxide (KOH) is dissociated into potassium (K + ) and hydroxyl (OH – ) ions. The hydroxyl (OH – ) ions go toward the negative electrode. The negative electrode releases the electron and the positive electrode receives it through external connection. This causes current to flow through the charge from the positive to the negative electrode.

Ni-Cd battery discharge

Reaction at the negative electrode

Cd + 2OH ———-> Cd(OH) 2 + 2e –

Reaction at the positive electrode

NiO(OH) +H 2 O + 2e – ———->Ni(OH) 2 + AH –

General Reaction

Cd + 2NiO(OH) + 2H 2 Ó ———->2Ni(OH) 2 +Cd(OH) 2

The discharge rate varies depending on the size of the battery. A standard AA battery can deliver a current of approximately 1.8 amps and a size D battery can deliver a current of approximately 3.5 amps.

Charging Ni-Cd batteries

When charging, the charger is connected to the terminals. The reaction is reversed upon discharge. The positive electrode converts Ni(OH) 2 to NiO(OH) and releases the electron. The electron is taken by a negative electron from external connections and converts Cd(OH) 2 to CD.

Ni-Cd battery charging

Reaction at the positive electrode

Ni(OH) 2 + AH – ———-> NiO(OH) +H 2 O + 2e –

Reaction at the negative electrode

Cd(OH) 2 + 2e – ———-> Cd + 2OH

General reaction

2Ni(OH) 2 +Cd(OH) 2 ———-> Cd + 2NiO(OH) + 2H 2 Ó

At the end of the charge cycle, the cells emit gas and this will also occur when the cell is overcharged. From this gas, the water in the electrolyte will decompose into hydrogen at the negative electrode and oxygen at the positive electrode. This gasification depends on the voltage used to charge the cell and the temperature. To fully charge the Ni-cd battery, slight gasification must occur, so some water is used from the electrolyte concentration.

There are two methods for charging ni-cd batteries. Slow charge and fast charge.

- Trickle Charge: – The trickle charge current is about 0.1C and will not damage the cell when fully charged. This method is also used to overcome self-discharge of ni-cd batteries.

- Fast charging: – In fast charging, the cell is charged at a constant current of about 1C. C is the battery capacity, if you are using a 4Ah battery then 1C means 1 x 4 = 4A. Once fully charged, which can be detected by the charge detection algorithm given below. The current will be reduced to 0.1C and a trickle charge will be applied. Trickle charging is charging at the same rate that the battery self-discharges. This will keep the battery fully charged.

The full charge detection algorithm can use two negative Delta V or temperature factors.

If the algorithm uses temperature to detect, the temperature will be 45 degrees for fast charging and 50 degrees for slow charging.

In the negative delta V detection algorithm, the voltage drops after a full charge. Detecting this drop can be used to detect the state of full charge. This method is called negative delta V. This method provides accurate full charge detection.

Ni-MH Batteries

Firstly, the Ni-MH battery was invented in 1967 by the Battelle-Geneva Research Center. It was then launched in 2005 by Sanyo, under the Eneloop brand. In this battery, a positive electrode (cathode) is made of nickel oxide hydroxide and a negative electrode is made of a hydrogen absorbing alloy (metal hydride). The electrolyte used is potassium hydroxide (KOH) concentrated with distilled water.

Ni-MH Battery

This battery has a discharge/charge cycle of about 180 to 2,000 cycles . This depends on several factors, such as how you are charging or discharging the battery.

This battery is almost similar to Ni-Cd battery. The nominal voltage of the Ni-MH battery is 1.2V for a single cell. But at full charge, the voltage is 1.5V and the full discharge voltage is 1.0V. The current capacity of this battery varies according to its size, an AA battery can be available close to 2000mAh.

Discharging Ni-MH batteries

The discharge reaction starts when the load is connected to the terminals. Metal hydride (MH) reacts with OH ions to form M and water, and also releases an electron. The electron is taken by NiO (OH) through an external charge. This causes electricity to flow through the load.

Discharging Ni-MH battery

Reaction at the negative electrode

MH + OH – ———->M +H 2 O + e –

Reaction at the positive electrode

NiO(OH) +H 2 O + e – ———->Ni(OH) 2 + AH –

General Reaction

NiO(OH) +MH ———->Ni(OH) 2 +M

Normally Ni-MH battery discharges at a rate of 3C (where C is the battery capacity, but high quality battery can discharge up to a rate of 15C.

Charging Ni-MH batteries

When charging, the charger is connected to the battery terminal and the charging reactions are inverse to the discharging reactions. The positive electrode converts Ni(OH) 2 to form NiOOH, water and releases an electron. This electron is removed by the negative electrode of the outer wire and again from the MH.

Ni-MH battery charging

Reaction at the positive electrode

Ni(OH) 2 + AH – ———-> NiO(OH) +H 2 O + e –

Reaction at the negative electrode

M +H 2 O + e – ———->MH+OH –

General Reaction

Ni(OH) 2 + M ———-> NiO(OH) +MH

Ni-MH battery charging chemicals utilize constant current and constant voltage algorithms which can be divided into four parts given below.

- Slow charging:- When the battery is deeply discharged, it drops below 0.9V per cell. the constant current of maximum 0.1C used to charge the battery is called trickle charging.

- Constant current:- When the voltage is above 0.9V per cell, constant current is applied in the range of 0.2C to 1C to perform constant current charging.

- Termination of Charge: – Full battery charge can be detected by a full charge detection algorithm explained below. After full charge, trickle charging is used at the self-discharge rate to maintain the battery's full charge.

The full charge detection algorithm can use two negative Delta V or temperature factors.

If the algorithm uses temperature to detect, the temperature will be 45 to 50 degrees to detect full charge.

In the negative delta V detection algorithm, the voltage drops after a full charge. Detecting this drop can be used to detect the state of full charge. This method is called negative delta V. This method provides accurate full charge detection.

Lithium-Ion Batteries

Firstly, a lithium-ion battery was developed by Akira Yoshino in 1985. The positive electrode (cathode) is made of lithium cobalt oxide and the negative electrode (anode) is made of graphite. Lithium salt as an organic solvent is used as an electrolyte. A separator is used to separate electrodes

Lithium Ion Battery

This battery has a discharge/charge cycle of about 400 to 1200 cycles. This depends on several factors, such as how you are charging or discharging the battery.

The nominal voltage of the lithium-ion battery is 3.60 V. When the battery is fully charged, the voltage is about 4.2 V. When the battery is fully discharged, the voltage is about 3.0 V Lithium-ion battery comes in different sizes and shapes, capacity is also available as per requirements.

Discharging Lithium-Ion Batteries

At the time of battery discharge, the load is connected to the battery terminal. The lithium ion is released from the negative electrode and goes to the electrolyte. This lithium ion is absorbed by a positive electrode. The negative electrode also releases electrons that travel through an external wire to the positive electrode. This provides us with an electrical current for our circuit.

Discharging the lithium-ion battery

(Lithium-ion battery discharge)

Reaction at the negative electrode

LiC 6 ———-> C 6 +Li + +e –

Reaction at the positive electrode

CoO 2 + Li + e – ———-> LiCoO 2

General Reaction

LiC 6 + CoO 2 ———->C 6 + LiCoO 2

The lithium-ion battery can discharge at a rate of 10C (where C is the battery capacity). If your battery can supply 1000mAh, the discharge rate will be 10 x 1000 = 10000mAh.

Charging lithium-ion batteries

When charging the lithium-ion battery, the battery is connected to the charger. The positive electrode loses a negatively charged electron. To maintain this charge balance at the negative electrode, an equal number of positively charged ions are dissolved in the electrolyte solution. These lithium ions travel to the positive electrode, where they are absorbed by the graphite. This absorption reaction also deposits electrons on the graphite anode to “tie” the lithium ion.

Lithium-Ion Battery Charging

Reaction at the positive electrode

LiCoO 2 ———->CoO 2 + Li + e –

Reaction at the negative electrode

C 6 +Li + +e – ———-> LiC 6

General Reaction

C 6 + LiCoO 2 ———-> LiC 6 + CoO 2

Lithium-ion battery charging chemicals utilize constant current and constant voltage algorithms that can be divided into four parts.

- Slow charge: – When the battery is deeply discharged, it drops below 3.0V per cell. the constant current of maximum 0.1C used to charge the battery is called trickle charging.

- Constant current:- When the voltage is above 3.0V per cell, constant current is applied in the range of 0.2C to 1C to realize constant current charging.

- Constant voltage:- when the voltage is reached at 4.2 V per constant current charging cell. Constant voltage is applied until the current drawn by the cell drops to zero, which maximizes battery performance.

- Termination of Charging: – The end of charging is detected by an algorithm that detects the range of current falling from 0.02C to 0.07C or uses a timer method. It detects when a constant voltage stage is initiated and shuts down the charger after 2 hours of constant voltage stage.