In the dynamic field of sensor technology, linear variable differential transformers (LVDTs) are indispensable components for precise measurements and controls. As we move into the ever-evolving landscape of industrial instrumentation, the focus is increasingly on LVDT converters. This article delves into a comprehensive exploration of LVDT technology, unravels its basic workings, analyzes its diverse applications across various industries, provides insights into choosing the right converter for specific needs, and analyzes new trends and innovations with a look into the future. Join us on this journey as we unlock the potential of LVDT transducers and understand their past, present and future importance in shaping the landscape of modern sensing technology.

Understanding LVDT Technology

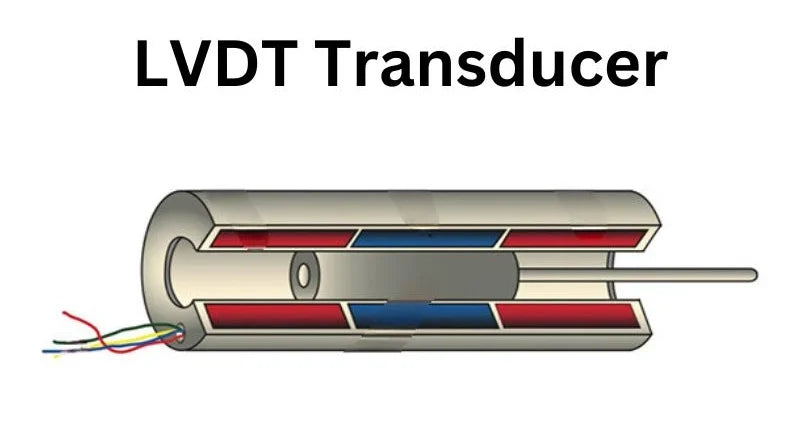

LVDTs (Linear Variable Differential Transformers) work by electromagnetic induction. These devices consist of a primary coil, two secondary coils and a ferromagnetic core and measure linear displacements accurately. AC voltage induces voltages in the secondary coils and the position of the core determines the amplitude and phase of the induced voltages. This contactless method guarantees reliability and durability.

How does an LVDT converter work?

LVDT converters work based on electromagnetic induction. The device consists of a primary coil, two secondary coils and a ferromagnetic core. When an alternating voltage is applied to the primary coil, it induces voltages in the two secondary coils. The position of the ferromagnetic core determines the amplitude and phase of the induced voltages, allowing accurate measurement of linear displacement.

Advantages of LVDT Converter

LVDT converters offer several advantages that contribute to their widespread use:

- High Accuracy: LVDTs provide accurate and repeatable measurements, making them suitable for applications where accuracy is important.

- Durability: As there is no physical contact between the core and coils, LVDTs have excellent reliability and longevity.

- Wide temperature range: These converters can operate effectively over a wide temperature range and are therefore suitable for different environments.

- Minimal friction: Because LVDTs are not based on sliding contacts, they have minimal wear and friction, reducing the need for frequent maintenance.

Cross-industry applications of LVDT converters

LVDTs have a wide range of applications across industries. In the aerospace industry, they measure structural deformations to ensure aircraft safety. In the automotive sector, suspension travel is monitored to improve driving comfort. Medical applications include precise measurements in infusion pumps and robotic surgery, demonstrating the adaptability of LVDTs to different industrial needs.

LVDT Converters in the Aerospace Industry

LVDT converters are widely used in the aerospace industry, where accuracy and reliability are of utmost importance. These devices play a key role in measuring the deflection of structural components, ensuring aircraft safety and performance.

Integration of the automotive industry

In the automotive sector, LVDT converters contribute to vehicle safety and performance. They are used in suspension systems to monitor and control the displacement of various components to improve driving comfort and stability.

Medical Applications of LVDT Transducers

LVDT transducers are essential in medical devices such as infusion pumps and robotic surgery systems. Its high precision and reliability contribute to the precise administration of medications and the success of complex surgical procedures.

Choosing the Right LVDT Converter

When selecting the appropriate LVDT converter, factors such as measuring range, environmental conditions and output types must be taken into consideration. Calibration and maintenance are essential to ensure long-term reliability.

Factors to consider

When selecting an LVDT converter for a specific application, several factors must be considered:

- Measuring Range: Choose an LVDT that provides the linear displacement range required for your application.

- Environmental conditions: Consider the operating environment, including temperature, humidity, and possible exposure to corrosive substances.

- Output and signal processing: Different applications may require specific output types and signal conditioning options. Ensure compatibility with your system.

Calibration and maintenance

Calibration is critical to maintaining the accuracy of LVDT transducers over time. Regular calibration and proper maintenance, including keeping the transducer free of contaminants, contribute to long-term reliability.

Future trends for LVDT converters

Future trends for LVDTs include IoT integration, durable materials for demanding environments, and miniaturization for more compact designs that promise improved features and efficiency.

IoT integration for better connectivity

The future of LVDT technology is characterized by seamless integration with the Internet of Things (IoT). This innovation aims to improve connectivity and provide real-time data insights. By integrating LVDTs into IoT platforms, industries can achieve new levels of monitoring, control and predictive maintenance. This connectivity speeds data collection and opens doors for remote operation and monitoring, revolutionizing the way industries use LVDT converters.

Advanced materials for greater durability

Innovations in materials will redefine the durability of LVDT transducers, especially in demanding environments. Researchers are exploring materials that can withstand extreme temperatures, corrosive substances and harsh operating conditions. This focus on advanced materials ensures that LVDTs can maintain their accuracy and reliability in different industrial environments, ultimately extending their service life and reducing the need for frequent replacements.

Miniaturization for compact, efficient designs

A key trend shaping the future of LVDTs is continued miniaturization. Engineers and researchers are working to reduce the size of LVDT converters without compromising their performance. Miniaturization allows these devices to be better adapted to applications with limited space and increases energy efficiency. Smaller and more compact LVDTs can be seamlessly integrated into various systems, opening up new possibilities for use in new technologies and compact devices.

Considering these future trends and innovations ensures that LVDT converters play a central role in sensing technology and meet the growing needs of industries and applications.

Conclusion

In summary, the continued importance of linear variable differential transformers (LVDTs) in sensing technology is undeniable. From their complex electromagnetic functionality to their central role in industries ranging from aerospace to medical applications, LVDT transducers have proven to be a cornerstone of accuracy and reliability. As we stand on the cusp of technological evolution, the future promises even greater progress with the integration of IoT, advancements in durable materials, and the continued quest for miniaturization. The adaptability and versatility of LVDT technology ensures its continued relevance and offers a promising development that perfectly adapts to the evolving needs of different industrial scenarios. Leveraging these innovations ensures that LVDT transducers meet and exceed expectations for accuracy, durability and efficiency in the ever-expanding field of sensing applications.

Common questions

What is the main advantage of using LVDT converters in measurement applications?

The main advantage of LVDT transducers is their high precision and repeatability. Thanks to their non-contact design and electromagnetic induction principles, LVDTs provide accurate measurements, making them ideal for applications where accuracy is of utmost importance. Its reliability and consistency ensure accurate data collection in a wide variety of industrial environments.

How do environmental conditions affect the performance of LVDT converters?

Environmental conditions such as temperature and humidity can affect the performance of LVDT converters. These sensors are designed to operate efficiently in a variety of conditions, but extreme temperatures or exposure to corrosive substances can affect their accuracy. Proper consideration of environmental factors in selection and regular maintenance contributes to optimal performance and longevity.

Are LVDT converters suitable for applications with limited space?

Yes, LVDT converters are suitable for applications where space is limited. Ongoing miniaturization efforts have led to the development of compact, efficient designs without sacrificing performance. The smaller size of these converters allows perfect integration into systems with limited space, expanding their applicability in new technologies and compact devices.