STEEL IN THE BRAZILIAN INDUSTRY

Sheet Metal Springback: Mechanism and Control S...

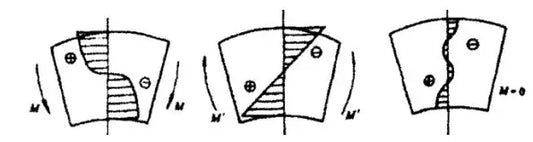

Springback is one of the most common forms of scrap in sheet metal processing, as well as one of the technical difficulties in bending processes. At the same time, it...

Sheet Metal Springback: Mechanism and Control S...

Springback is one of the most common forms of scrap in sheet metal processing, as well as one of the technical difficulties in bending processes. At the same time, it...

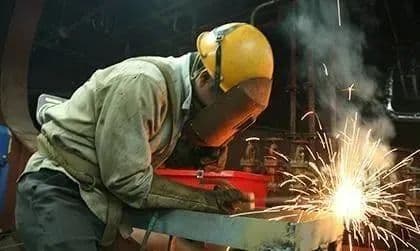

4 reasons for electrode sticking during welding

Sticky electrode refers to an abnormal welding between the electrode and the workpiece, causing the electrode to adhere to the workpiece. This can cause the electrode to be torn off...

4 reasons for electrode sticking during welding

Sticky electrode refers to an abnormal welding between the electrode and the workpiece, causing the electrode to adhere to the workpiece. This can cause the electrode to be torn off...

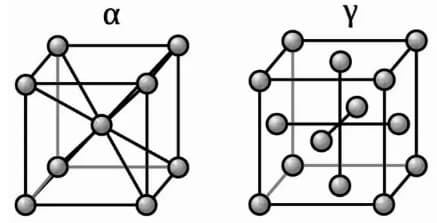

Exploring the crystal structures of austenitic,...

Solid matter in nature can be classified into two categories: crystalline and amorphous. A crystal is a solid with a regular geometric shape formed through the process of crystallization. In...

Exploring the crystal structures of austenitic,...

Solid matter in nature can be classified into two categories: crystalline and amorphous. A crystal is a solid with a regular geometric shape formed through the process of crystallization. In...

10 types of cracks in steel tempering: analysis...

1. Longitudinal crack The cracks are axial, thin and long in shape. When the matrix is completely quenched, i.e. centerless quenching, the center is transformed into centerless quenched martensite.

10 types of cracks in steel tempering: analysis...

1. Longitudinal crack The cracks are axial, thin and long in shape. When the matrix is completely quenched, i.e. centerless quenching, the center is transformed into centerless quenched martensite.

6 FAQs About Bolt Fatigue Calculation: Answers ...

1. What are the factors that affect the fatigue strength of bolts? There are several factors that can affect the fatigue strength of a connection, including the material used, structural...

6 FAQs About Bolt Fatigue Calculation: Answers ...

1. What are the factors that affect the fatigue strength of bolts? There are several factors that can affect the fatigue strength of a connection, including the material used, structural...

Maximize CNC Plasma Cutting Machine Performance...

I. Maintenance and care of CNC plasma cutting machine The working environment of CNC cutting machine is relatively harsh, with a significant amount of metal dust. Therefore, the...

Maximize CNC Plasma Cutting Machine Performance...

I. Maintenance and care of CNC plasma cutting machine The working environment of CNC cutting machine is relatively harsh, with a significant amount of metal dust. Therefore, the...