With the growing demand for cutting-edge technology, lasers are increasingly being used for a variety of purposes. Lasers are used for various manufacturing and forming processes. Laser engraving is a faster method than annealing or engraving, and this feature makes it the fastest laser marking process. One of the most common metals used for laser engraving is aluminum. Before starting a laser engraving project, read and learn more about it

What is laser engraving?

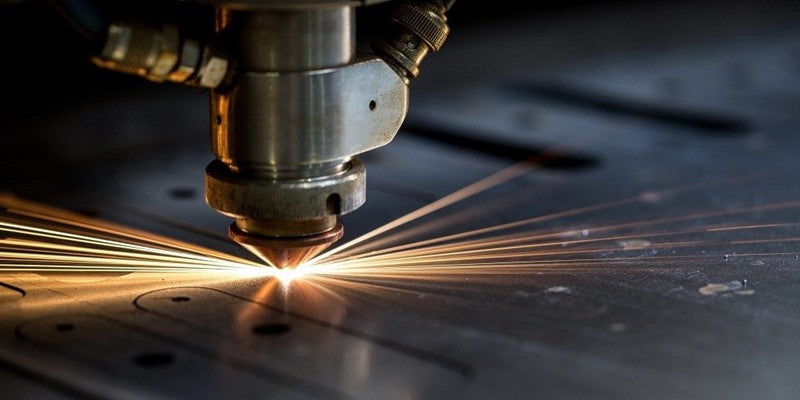

Laser engraving uses a laser beam to create markings on a surface. This happens by releasing a large amount of energy at specific intervals. This can be used for various purposes like engraving or cutting.

In laser engraving, the extreme heat from the laser melts the surface of metals after coming into contact with the metals. After melting, the melted material expands and leaves marks on the surface of the material. This process involves melting the surface of a product or part to leave marks on the surface.

Laser engraving designs are created in graphic design software. This graphic design software supports vector files. Once created, the design is saved as a vector file and sent to laser engraving machines for printing. Laser engraving machines use a computer-controlled router to read vector files. It also determines the pattern of laser movement to create the desired design.

Typical materials: aluminum engraving

Laser engraving can be used on almost all metals, including zinc, steel, lead, stainless steel, magnesium and anodized aluminum. Aluminum engraving is often used to engrave aluminum.

Aluminum etching is a process that uses chemical agents or acids to precisely and selectively dissolve the metal to produce the desired aluminum parts or components. The result is stress-free and burr-free components. This process allows parts with more precise characteristics to be produced quickly and safely.

Laser engraving process

During laser engraving, the laser beam is pulsed, releasing high energy. A 100W pulsed laser can deliver 100,000 pulses, with each pulse containing 1 millijoule of energy. Laser engraving requires less energy per area than metal engraving.

During laser engraving, the beam strikes the surface of the components, which in turn absorbs the beam's energy and converts it into heat. Furthermore, it also converts most of the energy of the reflected beam into heat. The material must absorb energy to cause its microsurfaces to melt and expand.

The temperature of the material increases after the beam energy is converted into heat. The surface formability of the component increases due to high heat, which leads to a change in shape. The surface of the material undergoes several changes after being melted and cooled in a short period of time. Changes in surface roughness create permanent, high-quality marks on the surface of the material.

How to Engrave Aluminum Plates in Easy Steps

You can easily engrave the desired image or design on an aluminum plate. However, as this process involves the use of hazardous chemicals, you must take necessary precautions before undertaking this task. For a simple procedure you will need some materials, for example:

- aluminum plate

- A design for engraving and gloves

- Hydrogen peroxide and hydrochloric acid (you can mix them in a 2:1 ratio. This depends on the concentration of peroxide. You may need to change the mixture. Most often, 11 vol of peroxide is used).

- A shallow plastic container (for mixing the peroxide with the acid)

- Eye protection glasses and protective clothing

- Laser printer ink (white or black)

- Another container with water (to rinse the plate)

- Some PNP projects

You should perform this procedure in an open, ventilated area so that dangerous and harmful gases, vapors and water cannot harm you and the surrounding area.

Step 1: Creating the design and printing in PNP

You can create a drawing in any vector application, and you must flip the drawing before printing. You can print your design on a sheet of paper. Pull a piece of PNP Blue from the edge of the design on the printed sheet of paper. After pasting the blue PNP onto a sheet of paper, set up a laser printer to print a good quality image.

Step 2: Prepare and clean the aluminum plate

In step 2, you need to prepare and clean the aluminum plate. First, cut as needed or desired, remove the dirt, clean the board with water and let it dry a little.

Step: 3 – Transfer project

Now transfer your drawing to the aluminum plate. It must be well aligned. Secure each side of the blue PNP with tape and protect from heat by placing a few pieces of fabric on the board.

You can heat the toner with an iron and cover all sides. The transfer is complete when it turns black. Remove the tape and place it on PNP Blue. After placing the PNP Blue, remove it and let it cool.

Step 4 – Apply the missing mark and engrave the aluminum plate

You can fix the missing marks with paint or marker and let the paint cover any missing areas. In the open area, use the plastic container to mix peroxide and acid. Mix in the right proportion, add hydrogen peroxide and then add acid.

The mixture reacts after being placed in the container. Remove the aluminum plate and clean it well with water. Remove any tape and clean again.

Step 5: Painting and Finishing the Panel

Spray paint on the panel and let it dry for better customization. Remove excess color with a towel or nail polish. After the paint has dried, remove excess paint with sandpaper. After this step, rinse the board well and let it dry. Now the aluminum engraving is completed.

Types of laser machines are used to engrave aluminum

The laser machine can cut various materials such as paper, wood, acrylic and MDF. Engravings are possible on leather, wood, glass surfaces and various metals. There are different types of laser machines.

fiber laser

Both natural and anodized aluminum can be engraved with a laser engraving machine. Among laser machines, fiber lasers are considered perfect for engraving anodized and natural aluminum. Fiber lasers are used because aluminum is etched with metals and metals respond better to fiber lasers.

CO2 laser and diode laser

Natural aluminum can be engraved with CO2 lasers and diode lasers. To do this, the aluminum is coated with a marker spray such as Cermark or paint. Anodized aluminum, on the other hand, can be engraved using a 60W CO2 laser and a 10W diode laser. Aluminum is engraved directly with these engraving machines without the need for additional aluminum coating.

Difference Between Laser Engraving and Laser Engraving

Laser engraving and engraving processes are used in many industries to apply stamps, text logos, barcodes, etc. Although they are similar procedures, there are also differences.

cutting depth

The main difference between laser engraving and laser engraving is the depth of the cut. Laser engraving completely penetrates aluminum, while laser engraving makes a shallower cut that only partially penetrates the material.

Laser engraving is often used for anodized aluminum because it does not remove the anodized layer. This process can be used for items like serial numbers, barcodes, or other graphics that need to be visible but not too deep.

Material hardness

Both engraving and laser engraving can be used to create high-quality permanent markings on a variety of materials. However, laser engraving is typically best for marking flat, hard surfaces, while laser engraving works well on softer materials or curved surfaces.

training

Laser engraving involves creating a mark by melting and expanding metals using a laser. It is part of a broader category. In contrast, laser engraving uses a laser machine to create a depression after the material is removed. Laser engraving technology involves vaporizing the material.

durability

Laser engraving creates a more permanent and durable mark than laser engraving. A laser engraving system is typically effective for components subject to high levels of wear.

Production volume

Laser engraving is more suitable for larger production volumes as the process is faster and more efficient. Laser engraving, on the other hand, is more time consuming and is therefore better suited for smaller production quantities.

Common Laser Engraving Applications

Laser engraving can create permanent markings. These part marking methods are mainly used for a wide variety of materials, making this marking method a smart choice for various industries. Due to high demand, it is widely used in various industries, including aerospace, medical, automotive, military and defense, electronics, and industrial and tool manufacturing.

Laser engraving is used in manufacturing because it is used to create permanent markings and can physically remove material from metals at high speeds. Marks text logos, serial numbers, 2D data and barcodes.

It is generally used before coating the material to create raised markings. These raised markings help maintain traceability after coating the material. The process is mainly used for coated automotive parts and extrusion.

What needs to be taken into account when engraving with a laser

Laser engraving is undoubtedly a versatile process and an ideal solution for laser marking metals. It's important to know what type of technology you need for marking. In addition to the marking method, a crucial factor is the type of laser engraving technology used for marking. Many variables can affect your product on laser engraving machines.

Is the laser engraving machine compatible with your project? It must be compatible with the files you created according to your needs. However, proper precautions are necessary to achieve the desired results. The following items must be considered during laser engraving.

- complexity

- Cost

- project

- Time

- Quality of materials

- precision

Considering all of the above, you can get the required material design more accurately within your budget and desired time.

Choose laser engraving to mark your pieces

Laser engraving is an important process for marking machined parts. Among all metals, aluminum, the most common metal, is widely used for laser engraving due to its high conductivity, versatility and corrosion resistance.

During the process, metals are melted by the laser beam and leave traces on the metals. Aluminum engraving is usually done with fiber lasers and produces amazing results.

Laser engraving is considered better than laser engraving because it takes less time as the metals melt during the process, while laser engraving takes longer as the metal evaporates. Various industries use laser engraving for manufacturing purposes considering time, cost, accuracy, etc.