What is a heavy duty butterfly valve?

A heavy-duty globe valve is a valve in which the stem is not collinear with the centerline of the disc, but is offset from the center. There are two compensation categories of this valve, namely double and triple compensation. The use of the offset design helps to improve a consistent, tight seal against the valve seat and also reduces frictional wear. The heavy-duty shut-off valve can be used to shut off and throttle fluid flows. Heavy-duty globe valve manufacturers produce this valve to handle various fluids, from general fluid flows to viscous and corrosive fluids. Corrosive liquids can be gases or vapor. Heavy-duty shut-off valves are generally large, e.g. B. with a diameter of 60 inches. These valves are made from durable materials such as carbon steel and stainless steel. Manufacturers of heavy-duty globe valves design these valves to operate over a wide temperature range from -28 to ÓC to 500 ÓC . The choice of operating temperature depends on the materials from which the valve is made. Heavy-duty butterfly valves are operated manually or via actuators. These valves are operated using the quarter-turn principle used in ball valves. This is the principle where the handle is rotated 90 degrees. Ó Degrees to open or close the valve as needed.

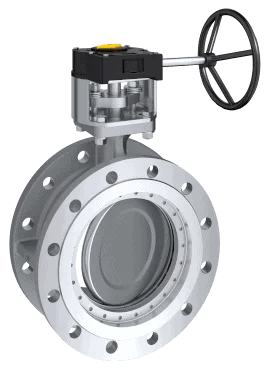

Figure: Heavy-duty butterfly valve.

Components of a high performance butterfly valve

valve body

This is the component responsible for housing the internal parts. The body is generally very stable compared to other parts to ensure that it can support the weight and prevent damage to the valve from falling objects. The high strength also helps the valve withstand fluid pressure. Some of the materials that heavy-duty butterfly valve manufacturers use to create the body include nickel alloys, stainless steel, nodular iron, and carbon steel.

stem

This is a metal component that connects the handle or actuator to the valve disc. The shaft rotates when the handle is turned. The function of the stem is to transmit the torque applied by the valve operator to the crank or by the actuator to the disc.

Steering wheel/drive

The handwheel is used in heavy-duty manual butterfly valves, while the drive is used in automatic valves. The function of this component is to provide the force necessary to close or open the flap. The handle is connected through the spindle to the flap closing and opening element, known as the disc.

Discount

This is the part of a high-performance valve that allows and blocks fluid flow as needed. The disc receives power to start and stop the valve from the handwheel or actuator.

Seat

This component is placed inside the valve body and provides a surface on which the disc rests when the valve stops. The seat ensures that no fluid can escape when the valve closes. The material from which heavy duty butterfly valve manufacturers make the seat is very important as it determines where the valve can be used in relation to the temperature and type of media.

poetry

This is a seal between the valve and tube mating surfaces that prevents fluid leaks. The seal is held in position by the high strength of the valve bolts and nuts.

Packaging

This is a sealing element between the shaft and the housing that prevents fluid from escaping along the shaft.

Figure: Components of a high-performance butterfly valve.

How does a heavy duty butterfly valve work?

This valve is operated with a handwheel/lever or actuator. A handwheel or hand lever is used on manual valves and is used for the operator to apply force to start and stop the valve. Actuator is used in automatic valves to provide the torque required to start and stop the valve. To open a heavy-duty globe valve, the stem is rotated 90 degrees. Ó Degrees counterclockwise by torque applied by the actuator or handwheel as needed. At the same time, the disk rotates the same 90 ° degree angle. This rotation forces the disc to align parallel to the fluid flow, leaving an unobstructed path. To close the valve, the stem and disc are rotated 90 degrees in the opposite direction (clockwise). Ó Only a 1 degree angle. This aligns the disc perpendicular to the flow path and prevents fluid from flowing through the heavy-duty shut-off valve. These valves are also used in throttling applications where the valve disc is rotated slightly to allow a certain amount of fluid to pass through. Manufacturers of heavy-duty globe valves recommend using these valves in throttling applications where there is only a small pressure drop.

Figure: How a high-performance butterfly valve works.

Heavy Duty Butterfly Valve Types

Heavy Duty Double Flange Butterfly Valve

This is a heavy duty double flange end stop valve. Flange ends are located on the inlet and outlet sides of the valve. These flange ends have holes. This type of valve connects to a pipe that has flange ends with the same diameter and the same number of holes. High-performance shut-off valve manufacturers produce this type of valve for use at very high fluid pressures. With this type of valve, fluid leaks are unlikely to occur due to the airtight seal provided by the bolts and nuts used, as well as the gasket placed between the tube and the valve. However, this type of valve is heavy compared to other valves. The high weight is due to the many screws and nuts as well as the flange ends.

Figure: Heavy-duty double flange butterfly valve.

Heavy Duty Manual Butterfly Valve

This is a manually operated heavy-duty shut-off valve. Heavy-duty shut-off valve manufacturers manufacture this valve to be operated by a gear handwheel. The gearbox is housed in a gearbox. The gearbox is designed to change the direction of rotation of torque from the flywheel to the valve stem and finally to the disc. In most cases, the torque of the flywheel and valve stem are perpendicular to each other. Therefore, a bevel gear is used to convert the horizontal torque into the vertical direction. The gearbox also multiplies the torque applied by the valve operator, making it easier to open and close the valve. Heavy-duty manual shut-off valves are cheaper compared to actuated ones. However, these valves cause great fatigue to the valve operator, especially when high torque is required to start and stop the valve and the valve is operated frequently.

Figure: Heavy-duty manual shut-off valve.

Heavy Duty Motorized Butterfly Valve

This is a heavy-duty globe valve operated via actuators. The actuator is located at the top of the valve. This valve makes piping operations easier and more economical as it can be operated automatically without a valve operator. This helps reduce the cost of a valve operator. The actuated valves can also be controlled remotely, saving time. The function of the actuator is to provide the energy necessary to start and stop the valve. Heavy-duty globe valve manufacturers produce three types of these actuated valves:

- Heavy-duty hydraulic shut-off valve. This valve uses an actuator powered by hydraulic fluid. This valve is suitable for applications that require high torque as the use of incompressible hydraulic fluid helps to achieve high torque. However, this valve is affected by high temperatures and is therefore suitable for use in low temperature applications.

- Heavy-duty pneumatic shut-off valve. This is a valve that works with compressed air. The pneumatic drive used makes this valve suitable for a variety of applications, from low to high temperatures and from very clean to dirty applications.

- Heavy-duty electric shut-off valve. This valve uses an electrical actuator to start and stop fluid flow. This valve is suitable for use at low and high temperatures. Operation of this valve is possible in almost all industrial applications due to the availability of electrical power.

Figure: High performance controlled butterfly valve.

Application areas for high-performance butterfly valves

- These valves are used in municipal water supply and water treatment.

- They are used in mining.

- Heavy-duty butterfly valves are used in food and beverage processing because they are easy to clean. Furthermore, these valves rarely become clogged.

- They are used in steam power plants to control the flow of steam and water.

- Heavy-duty butterfly valves are used in the production of various chemicals.

- They are used in the paper and cellulose industry.

- These valves are used in the refining of petroleum products.

- High performance butterfly valves are used in fire protection.

Benefits of Heavy Duty Butterfly Valves

- Heavy duty butterfly valves work very quickly compared to gate valves and ball valves.

- These valves have short housings, which means they take up little space.

- Heavy duty butterfly valves are cheaper compared to other heavy duty valves.

- These valves are versatile, as their design allows them to be used in various industrial applications.

- No liquid comes out.

- Heavy-duty butterfly valves can be operated manually or using actuators as required.

- These valves have high resistance that allows them to work at high pressure and high temperatures.

- They can be used as shut-off or throttle valves.

- These valves have a simple and compact design.

- They are easy to clean, install and repair.

- They are lightweight compared to other valves.

- Its maintenance intervals and costs are lower compared to other valves.

Disadvantages of Heavy Duty Butterfly Valves

- These valves are expensive compared to other butterfly valves.

- These valves open while the valve disc is in the path of fluid flow, reducing fluid flow pressure.

- Heavy duty butterfly valves are only suitable for throttling purposes when the fluid pressure drop is small.

- The sealing of these valves is poor compared to other valves such as ball valves.

Troubleshooting Heavy Duty Butterfly Valves

Fluid leaking through valve-tube connection

- Loose screws and nuts. Tighten bolts and nuts to the torque recommended by the heavy-duty shut-off valve manufacturer.

- Damaged or worn seal. Replace the gasket.

Fluid leaking through shaft

- Worn or damaged stuffing box gasket. Replace the packaging.

- Worn sealing rings. Replace the sealing rings.

Internal fluid leak

- Worn seats. Replace the seats.

- The sealing rings are worn. Replace the sealing rings.

- Dirt in the valve. Open the valve and remove the dirt.

The valve is difficult to operate

- Foreign bodies in the valve. Open the valve and remove any foreign objects. Clean all internal components.

- Valve corrosion. Open the valve and remove the corrosion.

Heavy-duty butterfly valves are designed so that the stem is not collinear with the centerline of the valve disc, but is offset a certain distance. Staggered design criteria help ensure a consistent, tight seal and reduce frictional wear. Heavy-duty butterfly valve manufacturers design these valves for use in high-pressure applications because they can operate without leaks. These valves are also intended for use in high and low temperature applications, depending on the materials used in manufacturing the valve components. Heavy-duty butterfly valves are used for isolation and throttling applications. However, these valves are suitable for restricting fluid flow when there is a small pressure drop. These valves work by having a 90 ° degree rotation of the disc to open and close the fluid flow. This means that the valve operates very quickly compared to other valves.

High pressure butterfly valve manufacturers offer several types of these valves, including heavy-duty double flange butterfly valves, heavy-duty manual butterfly valves, and heavy-duty actuated butterfly valves. These shock absorbers are used in petroleum refineries, firefighting, water supply, chemicals, mining, food and beverage, steam power plants, and pulp and paper manufacturing, among others. The advantages of these flaps include fast operation, relatively small installation space, light weight, simple and compact design, and easy repair, installation and cleaning.