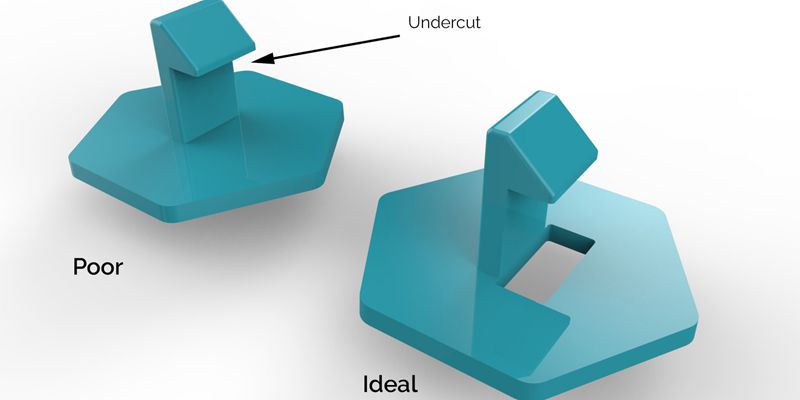

Undercut injection molding is a process for producing parts with complex shapes and features that prevent the part from being removed from the mold without damage. Undercutting capabilities in injection molding often increase the overall complexity and associated cost of a project. For these reasons, it is best to avoid them if possible.

In this article, we take an in-depth look at when cuts occur during injection molding and the different methods used to create cuts.

In what situations is undercut injection molding necessary?

There are many scenarios in which undercut molding becomes necessary, but here are some of the most common.

1. Custom Inserts

Using the undercut injection molding process, you can create custom inserts that fit larger parts. Machinists often use this type of insert in medical devices or products that require precise adjustment. You can also use cut-out inserts as an alternative to screws or rivets when attaching two parts.

2. Side holes

Undercut injection molding can create side holes that are difficult to create using traditional methods. Machinists often use side holes to mount components or attach them to other equipment. You can also use them for aesthetic reasons, such as: B. to add a design element or to release heat into the product.

3. Vertical curls

Vertical threads are another common use for undercut molding. These threads are commonly found on screws and nuts, but you can also use them as part of an assembly where multiple parts must be bolted together to function properly as a unit.

4. Barbed Connectors

Barbed joints require the male parts to be cut to form a lip that holds the female counterpart of the barbed joint.

5. Interlock Functions

If you are designing an interlocking feature such as tongue and groove, you will need to cut one side of the tongue so you can connect the side to the groove on the other side.

Challenges with undercuts in injection molding

The biggest challenges in undercut injection molding arise from the design, material selection, and aesthetic requirements of the machined part.

1. Lack of depth

The more complicated the arrangement, the more problems you will have with the recessed design. This is where it all starts. To get the best performance, you must control draft angles, cavity angles, and other complex angles. To reduce the possibility of difficult ejection, the coating must be applied to the correct substance by hand loading.

2. Difficulty in demoulding materials

Some materials can be difficult to achieve undercuts. For example, some materials, including glass-filled plastics, are more difficult to remove from the mold. As a general rule, the harder the material, the harder it will be to remove. Therefore, when using these harder materials, use as much draft as possible. Additionally, the solution used to optimize cuts will depend on the overall flexibility and elasticity of the material.

3. Aesthetic consideration

The aesthetic requirements of the project can represent another significant obstacle. For example, the undercut design option you use has certain limitations if you are working with a component where you do not want to have a noticeable parting line on injection molded parts or other aesthetic issues. Therefore, you will face additional difficulties.

Multiple options for successfully using undercuts in molded parts

To successfully achieve undercuts, only minor changes in shape and a high level of skill are required. Some of the designs that can help minimize molding defects and wear are as follows.

1. Use manually loaded inserts

Machine operators use manually loaded drills when an undercut is required when machining demanding features such as a sharply angled edge. They are also useful when an additional feature, such as a poorly positioned hole, makes it impossible to use a standard solution such as a bumpoff.

To use a manually loaded insert, the operator places one or more metal parts into the mold before injecting the plastic. The number and position of the parts depend on how many recesses the machined part requires. These metal pieces effectively create a void as they prevent plastic from flowing into the spaces they occupy.

After the operator opens the mold after producing the item, he must physically remove the manually loaded insert. The disadvantage is that this increases the cost and cycle time of injection molding because the operator must load and unload each cavity individually.

2. Placing partial lines

Sometimes it's easier to move the shape dividing line so that it overlaps an undercut. The reason for this is that when the feature is bisected by the parting line, the operator can release the component from the mold without the need for undercutting. Machinists can zigzag the parting line using this method to adjust different features, eliminating the need for undercuts. However, this method has limitations. These range from the geometry to the flow properties of the plastic.

3. Insert batting

Bump-offs are a good choice when working with flexible, stretchy fabrics. The process differs from standard injection molding only by the addition of a single insert. The operator removes this insertion first after completing the process. The vacuum it leaves behind gives the component some “leeway”. Once the insert is removed, the part can be removed from the mold. The “gap” allows the machinist to bend the part slightly when removing it from the mold, even if the undercut is present.

Although applying impulse points appears relatively simple from the outside, several things must be carefully considered when using them. First, the part must be elastic enough not to break when the machine operator bends it. The operator must also ensure that the tilt angle is between 30 and 40 degrees.

4. Parallel actions

In cases where an undercut is unavoidable, a lateral movement feature can help maintain part functionality. A lateral movement core is an insert inserted before the plastic is injected into the mold. When the operator injects the material into the mold, he is unable to fill the volume occupied by that insert. The machinist removes the insert after the molding process is complete.

However, unlike push-off, where the machinist removes the insert before the part, the side action cores are removed after the part is removed. Side actions also work best with rigid materials that do not adhere easily to the mold surface. A disadvantage of side actions is that each bet must be specifically designed, which makes the process more complex.

5. Use shutdown devices

Machinists use slide barriers when a feature, such as a hook protruding from the side of a mold, cannot be easily manufactured using another method. You insert a sliding barrier through the hole in the wall of the main component to create the cutout and hook. The other half of the shape creates the remaining hook feature.

The problem with slider clasps is that they need to be extremely tight. The reason for this is that plastic cannot evolve beyond form to function when you need to use it as two corresponding pieces of a tool. Otherwise, significant friction will occur when opening and closing the tool.

Additionally, you must taper each of these surfaces by approximately three degrees to avoid damage to the mold, which would quickly result in molds with an unacceptable surface. This is necessary because complete metal-to-metal contact only occurs when the mold is completely closed and a mechanical seal forms between the two surfaces.

Undercut applications in injection molding

Undercut injection molding is widely used in numerous industries due to its ability to produce products with undercut characteristics. We selected some of these industries and explain them below.

Consumer electronics

In this application we use other methods to form hard-to-reach features such as buttons and flanges. Undercuts are also used to create cavities for electronic components in consumer electronics such as cell phones and laptops.

Medical equipment

Other methods, such as injection molding or machining, allow you to use undercuts to create complex geometries that are not easily manufactured. In medical devices such as syringes and catheters, undercuts create grooves along their length to ensure proper function.

WayKen helps you solve the undercutting problem effectively

University Degree

There are countless reasons to use undercuts in your design process. First, when designing parts for injection molding, it is critical to determine the formability of your components. Whether it's a straight wall design or an undercut, you need to create the geometry to exact specifications to allow the plastic to flow properly and create a part with minimal defects.

Common questions

What are undercuts in injection molding?

A molding undercut is a depression or protrusion in a mold that prevents it from being pulled out of a one-piece mold. Undercuts on molded components prevent the part from being ejected directly from an injection molding machine. They can be internal or external recesses, with external recesses on the outside of the component and internal recesses on the inside.

What is the undercut procedure?

When removing the component from the mold, some mechanisms are needed to adjust the part of the mold that comes into contact with the recess so that the part can be removed from the mold, as the part cannot be removed directly without the device. This is the undercut procedure.

What is a “dividing line” in injection molding?

The parting line refers to the direction of the mold design line, or the point at which the machinist separates the two halves of the mold without damaging the part. The parting line is usually in the middle of the piece. However, this changes depending on the shape of the piece.