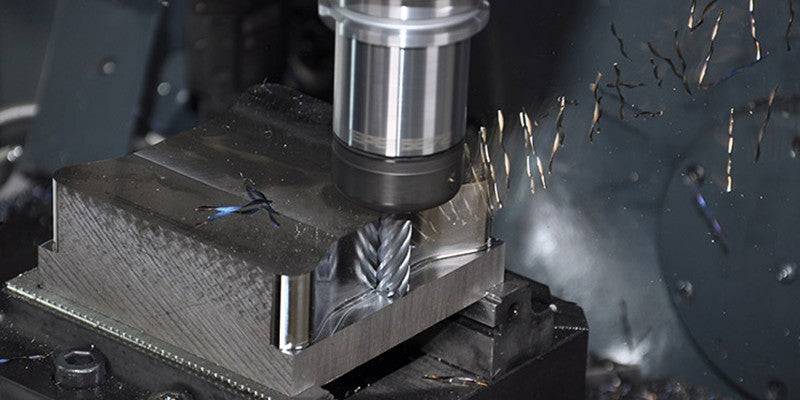

Stainless steel is one of the metals used in CNC machining due to its incredible versatility. It is used in several industries, including automotive, consumer goods, medical and aerospace. The versatility of stainless steel comes from its numerous benefits, from corrosion resistance to durability.

However, not all types of stainless steel are easy to process. Challenges can arise when CNC machining stainless steel. Keep reading.

Why choose stainless steel for CNC machining projects?

Stainless steel is an excellent material for CNC machining to create strong, durable items. Here are some reasons why you should choose stainless steel for CNC machining projects.

1. High tensile strength

Stainless steel has higher tensile strength than carbon steel, brass, and several types of aluminum alloys. The tension required to stretch a material to its breaking point is called tensile strength. This is an important feature for many products throughout their service life, especially for parts that are frequently folded and laminated.

2. Cryogenic resistance

Some types of stainless steel maintain their stability at different temperatures. For example, austenitic steels have excellent toughness and better tensile strength at subzero temperatures. However, it is important to note that not all types of stainless steel have this property.

3. Corrosion resistance

Stainless steel is highly resistant to corrosion and resists water stains and rust. This corrosion resistance makes stainless steel ideal for a variety of indoor and outdoor applications, including extreme temperatures and pressures. This property of stainless steel is due to the inclusion of chromium in the metal, which forms a thin layer that protects the steel when it comes into contact with oxygen.

4. Appearance

Stainless steel has a silvery white color that will not discolor or rust over time. It owes its appearance to the high chromium content. In addition to its resistance, stainless steel has other properties. This metal is used in many products due to its beautiful appearance.

Without sacrificing functionality, the CNC milled stainless steel part has a clean, modern appearance.

Challenges for Custom Stainless Steel Parts

Stainless steel alloys are between titanium and aluminum in terms of hardness, machinability, strength and temperature resistance. However, this also brings some challenges. Here are some of the challenges when machining custom stainless steel parts.

1. Overheating

In contrast to many other types of steel and metals, stainless steel is a poor conductor of heat. However, when machining stainless steel, it heats up quickly, which can damage both the stainless steel itself and the CNC tools and machines used during machining.

2. Difficult surface finish

Choosing the correct surface finish for CNC machined stainless steel parts is quite difficult. The reason for this is that, unlike other metals, the surface finish of stainless steel doesn't just influence its aesthetics. It also influences other properties such as corrosion resistance, electrical properties, impact resistance and weldability.

3. Technical knowledge

Processing stainless steel requires technical skill and care. The reason for this is that machining stainless steel is difficult because using the wrong cutting tool or speed can damage the material. This challenge makes processing stainless steel extremely laborious and time-consuming.

4. Poor machinability

Compared to other metals, stainless steel is much more difficult to work with. It also hardens so quickly that it is difficult to handle, which contributes to its poor workability. Therefore, special tools are required to process stainless steel.

Quick Tips for CNC Machining Stainless Steel

There are several challenges involved in CNC machining stainless steel, but there are ways to avoid this problem and ensure smooth machining. Here are some quick tips on CNC machining this metal.

Choose special mills and drills

It is best to use tools made from high-quality materials, such as molybdenum or tungsten HSS end mills and drill bits. When cutting stainless steel, they withstand the stress of the process with minimal wear. These tools also improve the surface finish. Avoid using tools that wear out easily, as this can reduce machining speed and increase production costs.

Manage the heat generated

One of the reasons CNC machining of stainless steel fails is heat. It's best to keep cutting speeds low and use refrigeration to control heat. It is also generally recommended to stop processing if the material becomes too hot.

Use grooving and chip breaking cycles

Using chip breaking and collection cycles in machining is one way to control chip formation. This prevents long, stringy chips. Another way to control chip formation is to check tools frequently, as worn cutting tools produce more chips.

Protect your workpiece from deformation

There are many factors that can deform a workpiece, including speed, feed, and cutting tools. Using a worn cutting tool would increase tool deflection, which in turn would cause parts to be out of tolerance and deformed. Therefore, it is important to respect the recommended speed and feed when machining stainless steel.

Stainless steel alloys available for CNC machining

Just as there are different types of titanium alloys, different stainless steel alloys are suitable for different purposes. Below are CNC stainless steel alloys that are ideal for CNC machining.

Class SS 17-4 (PH stainless steel)

This stainless steel contains up to 30% chromium. It is a type of precipitation hardened martensitic stainless steel.

Merits:

- Corrosion resistance

- High tenacity

- High strength

Disadvantages:

- Susceptible to heat damage

Used:

- oil and gas

- Aircraft turbines

- Nuclear reactions

SS303 (automatic stainless steel)

This austenitic stainless steel is easily machinable and readily available.

Merits:

- Good corrosion resistance

- Cheap

- Excellent machinability

Disadvantages:

- Not ideal for marine applications

- Does not harden when heat treated

Used:

- Nuts, Bolts and Nuts

- Aircraft Accessories

- Bushings

- Electronic hardware

SS304 (stainless steel)

This easily weldable stainless steel is one of the most commonly available grades.

Merits:

- Good weldability

- Good machinability

- Excellent cost

- Good corrosion resistance

Disadvantages:

- Highly susceptible to cracking and corrosion

Used:

- Architectural applications

- screws

- Heat exchanger

- Food handling

- Auto parts

SS416 (stainless steel cutting)

This is the most machinable stainless steel.

Merits:

- Moderate corrosion resistance

- Excellent machinability

- Excellent resistance

Disadvantages:

- Not ideal for marine environments

- Not suitable for chlorine-saturated environments

- Not available everywhere

- Poor weldability

Used:

- screws and nuts

- Shafts and gears

- Valves

- bombs

Surface Finish Options for Machined Stainless Steel Parts

Various options are available for surface processing of stainless steel parts. These options range from polishing and etching to brushing and sandblasting. The type of surface treatment of stainless steel surfaces often determines their resistance to corrosion.

polishing

There are numerous options for polishing the surfaces of stainless steel objects. Most stainless steel parts have a #3 or #4 finish or a #8 mirror finish. Many manufacturers prefer the reflected appearance of the mirror finish. High gloss surfaces are fantastic because they reflect light and look polished and shiny.

Blasting and pickling

The usual finishing of stainless steel objects is sandblasting and pickling. For this finish, stainless steel products are mechanically cleaned by bead blasting and then chemically cleaned by immersion in a stainless steel passivation tank. This finish appears matte and has a very modern look.

The sandblasted and stained finish goes well with an industrial look. This surface finish covers imperfections. Additionally, it is popular for marine projects and any other projects exposed to extreme weather conditions.

to brush

Similar to polished stainless steel, brushed stainless steel needs to be lightly sanded. With brushed steel, the underlying soft silver gray color is slightly visible. Because the brushed surface does not reflect light as much as the highly polished surface, the color of the steel is somewhat muted and many designers prefer this look.

Start machining stainless steel parts at WayKen

We are a rapid manufacturing company with many years of experience in CNC machining of metals, including stainless steel. We offer a wide range of material and finishing options, ensuring quality service and on-time delivery.

Concluding

Stainless steel offers several advantages to manufacturers. Its main advantages are corrosion resistance, the ability to withstand aggressive environments and a longer service life than many comparable metals.

Common questions

Why is stainless steel so difficult to work with?

Stainless steel has high strength and exceptional formability, making manufacturing a challenge. Furthermore, the material hardens and generates a lot of heat during the machining process. This increases wear on cutting tools.

What speed do you need to mill stainless steel?

In general, when milling stainless steel, an SFM of 100 to 350 is recommended, with a chip load ranging from 0.0005″ for 1/8″ end mills to 0.006″ for 1″ end mills.

Which quality of stainless steel is best suited for machining?

Due to its excellent feedability and speed, 430F grade stainless steel is the preferred grade in the machining industry. Grade 430F stainless steel is essentially ferritic and identical to 430, but contains more sulfur for better machinability.