1. Heat treatment process of aluminum and aluminum alloy

1.1 Purpose of heat treatment of aluminum and aluminum alloys

The aim is to heat aluminum and aluminum alloy materials to a certain temperature and keep them at that temperature for a certain period of time to obtain the desired structure and properties of the product.

1.2 Main heat treatment methods for aluminum and aluminum alloys and their basic principles

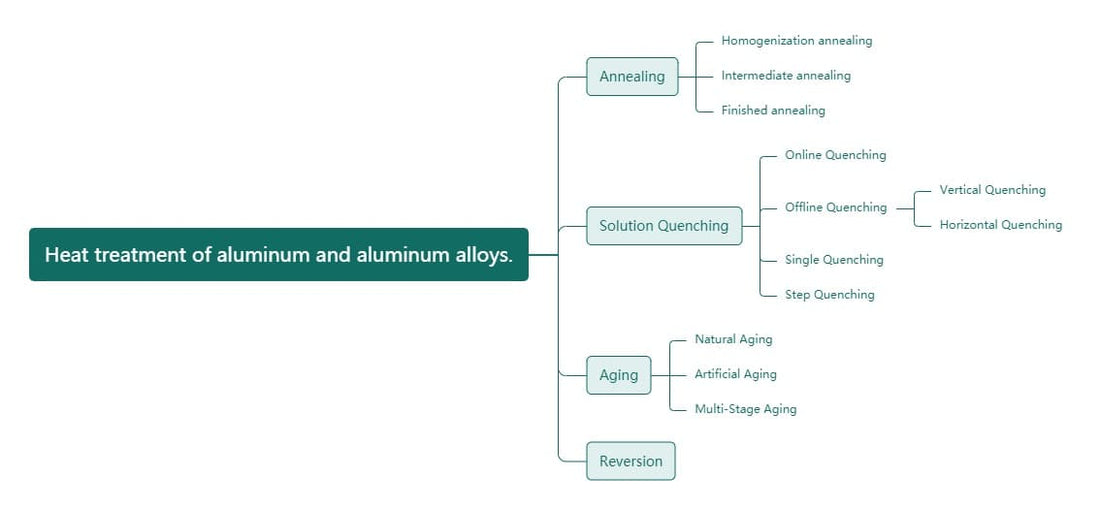

1.2.1 Classification of heat treatment of aluminum and aluminum alloys (see Figure 1)

1.2.2 Basic principles of heat treatment of aluminum and aluminum alloys

(1) Annealing: The product is heated to a certain temperature, maintained at that temperature for a certain period of time, and then cooled to room temperature at a certain cooling rate. Through atomic diffusion and migration, the structure becomes more uniform and stable, internal stresses are relieved, and the ductility of the material can be greatly improved, although the strength decreases.

① Ingot homogenization annealing: The ingot is kept at high temperature for a long period of time and then cooled at a certain rate (high, medium, low or slow) to homogenize its chemical composition, structure and properties. This can increase the ductility of the material by about 20%, reduce the extrusion pressure by about 20%, increase the extrusion speed by about 15%, and improve the quality of surface treatment.

② Intermediate annealing: Also known as local annealing or process-by-process annealing, it is done to improve the ductility of the material and eliminate internal stresses during processing. This involves keeping the material at a lower temperature for a shorter period of time in order to facilitate further processing or obtain a specific combination of properties.

③ Full annealing: Also known as final annealing, it involves heating the material to a relatively high temperature, keeping it at that temperature for a certain period of time, and obtaining a softened structure in a fully recrystallized state with better ductility and lower strength.

(2) Heat treatment and solution quenching:

This method involves heating aluminum alloy materials that can be strengthened through heat treatment to a relatively high temperature and keeping them there for a certain period of time. This allows the second phase or other soluble components of the material to completely dissolve in the aluminum matrix, forming a supersaturated solid solution. The material is then rapidly cooled to room temperature using a rapid quenching method. This creates an unstable state because the solute atoms are in a higher energy state and can precipitate at any time. However, the material at this stage has greater ductility and can undergo cold working or straightening processes.

① In-line quenching: For some alloys that are not highly sensitive to quenching, solution treatment can be carried out during high-temperature extrusion, followed by air cooling (T5) or water mist quenching (T6) to achieve certain structures and properties.

② Off-line quenching: For alloy materials that are highly sensitive to quenching, they must be reheated to a high temperature and maintained at that temperature for a certain period of time in a special heat treatment furnace. They are then quenched in water or oil with a transfer time of no more than 15 seconds to obtain certain structures and properties. Depending on the equipment used, this can be done through salt bath quenching, air quenching, vertical quenching or horizontal quenching.

(3) Aging: After solution heat treatment and quenching, the material is kept at room temperature or a higher temperature for a certain period of time. The unstable supersaturated solid solution will decompose and second phase particles will precipitate (or settle) from the supersaturated solid solution and distribute around the alpha aluminum (AL) grains, resulting in a strengthening effect called precipitation strengthening (or sedimentation).

Natural aging: Some alloys (such as 2024) can produce precipitation strengthening at room temperature, which is called natural aging.

Artificial aging: Some alloys (such as 7075) do not show obvious precipitation strengthening at room temperature, but demonstrate significant precipitation strengthening at higher temperatures, which is called artificial aging.

Artificial aging can be divided into underaging and superaging:

① Aging: involves controlling the aging temperature to be lower and the retention time to be shorter to obtain certain properties.

② Overaging: Ages at a higher temperature or for a longer period of time to obtain special properties or more comprehensive properties.

③ Multi-stage aging: It involves dividing the aging process into several stages in order to obtain certain special properties and good comprehensive properties. This can be divided into two-stage and three-stage aging.

(4) Reversion treatment: involves heating the product that has been quenched and aged at a high temperature for a short period of time in order to improve its ductility and facilitate cold bending or correct shape tolerances. This restores the product to a new defunct state.

2. Product status notation of aluminum and aluminum alloy

2.1 Basic product status codes as shown in Table 1:

Table 1: Basic Product Status Codes

| Code | Name | Explanation and Application |

| F | Free processing status | It is applicable to products without special requirements for hardening and heat treatment conditions during the forming process, and the mechanical properties of products in this state are not specified |

| O | Annealing state | Suitable for processed products that have undergone complete annealing to achieve the lowest strength |

| H | Work hardening state | It is applicable to products whose strength is improved through hardening. The product may (or may not) undergo additional heat treatment after work hardening to reduce strength. The H code must be followed by two or three Arabic numerals |

| W | Solid solution heat treatment state | Unstable state applicable only to alloys that undergo solution heat treatment and natural aging at room temperature. This status code only indicates that the product is in the natural aging phase |

| T | Heat treatment state (different from F, O, H state) | It is applicable to the T code of products that have been (or have not been) work hardened to a stable state after heat treatment and must be followed by one or more Arabic numerals |

2.2 Subdivision of status H (work hardening)

H1 – Simple hardening state. Applicable to products that have not undergone additional heat treatment and that have obtained the necessary strength only through hardening.

H2 – Work hardening and incomplete annealing state. Applicable to products where the degree of hardening exceeds the specified requirements for finished products and the strength is reduced to the specified target through incomplete annealing. For alloys that naturally soften at room temperature, H2 has the same minimum tensile strength value as the corresponding H3; For other alloys, H2 has the same minimum ultimate tensile strength value as the corresponding H1, but with slightly greater elongation than H1.

H3 – State of work hardening and stabilization treatment. Applicable to products whose mechanical properties have been stabilized after low-temperature heat treatment or due to heating during processing after work hardening. H3 status only applies to alloys that gradually age and soften at room temperature (unless stabilized).

H4 – State of hardening and painting treatment. Applicable to products that have been subjected to hardening and incompletely annealed due to painting treatment.

The second digit after H represents the degree of hardening of the product. Number 8 represents a difficult state.

Stabilization treatment: To avoid the softening phenomenon that occurs after prolonged storage of the alloy after cold working, the product is subjected to low-temperature annealing (heating at 150°C for 3 hours) after cold deformation. This can stabilize the mechanical properties of the alloy stored at room temperature.

2.3 Classification of annealing state code (O)

2.3.1 O1- Homogenization annealing.

2.3.2 O2- Incomplete (partial) annealing of the product.

2.3.3 O3- Complete annealing of the product.

3. Temperature control table for oven aging process

Combustion chamber:

Set temperature in temperature control table: 200-215℃

Temperature displayed in the temperature control table: 190-210°C

Temperature measured inside the oven: 200-210°C

Right rear fan: Set temperature for fan: 160-180℃

Temperature displayed on fan gauge: 200-210°C

Controlled temperature inside the oven: 200-210°C

Display: Temperature displayed in the temperature control table: 190-205°C

Temperature measured inside the oven: 200-210°C

Display: Temperature displayed in the temperature control table: 195-210°C

Temperature measured inside the oven: 200-210°C

4. Aging Furnace Energy Calculation

Motor (loss of electrical energy)

Burner (fuel loss)

Energy consumption for heating (cooling furnace, heating furnace)

Energy consumption for insulation

Insulation time Furnace failure due to aging (affects the hardness of the process)

Motor power: 40/55W/h, current: 81/98A, voltage: 380V, speed: 740/1480r/min

Multi-speed three-phase asynchronous motor with model YD2808-8/4.

Power distribution for aging furnaces

Model XL-21, rated voltage: 380V, rated current: 1A.

Question: The aging process of the aging furnace has only been classified according to the alloy status, but there are no clear specifications for different wall thicknesses of the same alloy. What is the maximum difference in wall thickness that can be aged together?

5. How to adjust the airflow at the extrusion outlet?

When the material at the extrusion outlet winds upward, it is necessary to appropriately reduce the upward air speed or close the upper fan; When the material at the extrusion outlet curves downwards, it is necessary to appropriately reduce the downward air speed or close the lower fan.

6. Guidelines for Executing the Aging Process (For Aging Furnace No. 3 in the Fourth Plant)

Based on data collected during a process investigation of this furnace, adjustments will be made to temperature control parameters during operation.

| Aging process | Executive Rules | ||||||

| League status | Waiting time ℃ | Isolation time h | Insulation time (based on wall thickness) h | Retention time temperature | |||

| 1.0mm | 1.0-4.0mm | 4.0-30mm | Fan Temperature Control Gauge | Combustion Engine Temperature Control Table | |||

| T6 | 175±8 | 8 | 8 | 8 | 10 | 171 | 171 |

| T5 | 200±8 | two | two | 2.5 | 3 | 197 | 197 |

| T52 | 235±8 | 1.5 | 1.5 | two | 1 | 230 | 230 |

Observation:

When at least two temperature control tables (fan and burner) reach the set temperature, the insulation time starts to be calculated.

The determination of the insulation time is based on the maximum wall thickness of the profiles inside the oven.

For profiles with higher basket density, it is necessary to appropriately extend the insulation time.

The aging process for states 6005-T5, 6005A-T5 and T6511 is carried out according to the T6 system.

If adjustments to the aging process are necessary for specific varieties, follow the instructions of the processing department.

When using double cavity molds for extrusion, attention should be paid to adjusting the flow rate of each hole to ensure consistency. During extrusion, aluminum flow problems in the ingots must be monitored.

To master the GB-5237 standard, it is important to understand twist, tolerances, and be able to use reference tables. Additionally, it is crucial to be proficient in identifying bubbles at the beginning and end of flat die profiles and note that combined dies, especially for tubes, may have fewer bubble problems.

7. Precautions for Extrusion

7.1 For 6xxx series alloys, the mechanical properties cannot be guaranteed at temperatures below 500°C and the surface quality is poor above 560°C.

7.2 Generally, the relationship between extrusion speed and temperature is as follows: high speed at low temperature, low speed at high temperature. The extrusion speed must be increased as much as possible, with temperatures set at the lower limit of the table, but the exit temperature must meet the specified requirements.

7.3 For molds with large extrusion parameters, especially those with many channel holes, the mold and aluminum bar temperatures should be adjusted to the upper limit. However, the speed must be reduced in the later stages of extrusion.

7.4 For special heat sink profile molds, the mold temperature must be above 480°C and the aluminum rod temperature must be above 530°C.

7.5 Mechanical performance standards vary between different countries and are related to the cross-section of the profiles. If the mechanical performance does not meet the requirements in the table, technical personnel should consult relevant national standards or communicate with the customer to determine whether they are qualified or should be released. Mechanical performance can be performed in accordance with technical agreements if there are specific user requirements.

8. Polishing materials

6463-T5 homogeneous rods should be extruded at low temperature and high speed (460-480℃).

8.1 Surface mechanical scratches caused by molds are a common problem.

8.2 Problems such as cutting and transfer segmentation causing scratches, abrasions, white lines, shiny lines, shrink marks, wool pulls, edges, waves, twists, geometric dimensional deviations, false scratches and orange peel frequently occur.

9. Mechanical Aluminum Surface Treatment

The surface effect after treatment can be divided into: a. Glossy surface b. Semi-matte surface c. Matte surface

The principle of polishing is to remove the protruding parts creating plastic deformations on the surface of the material through mechanical grinding, thus obtaining a smooth and polished surface. Fabric wheels, wool wheels, sandpaper, etc. are generally used.

The polishing process is generally divided into three stages: rough polishing, medium polishing and fine polishing.

Rough polishing: Polishing the surface with a hard wheel, which has a certain abrasive effect on the substrate that has or has not been polished

Medium polishing: Using a harder polishing wheel for further processing after rough polishing, it can remove the scratches left by rough polishing

Fine polishing: The last step of polishing, using a soft wheel to obtain a mirror surface with bright light, and has little effect on grinding the substrate.

10. Mechanical Drawing Method

10.1 Straight line drawing refers to the method of processing straight lines on the surface of an aluminum plate by mechanical friction.

10.2 Random drawing is a type of matte wire pattern obtained by moving the aluminum plate back and forth under a rotating copper wire brush.

10.3 Spiral polishing, also known as rotary polishing, is a wire pattern achieved by rotating and polishing the surface of an aluminum or aluminum alloy plate with a cylindrical felt or nylon corundum wheel mounted on a drill and mixed with grease. polish diluted with kerosene.

10.4 The threaded design is made on a machine.

11. Problem analysis of polishing materials

11.1 Why are there heavy mechanical risks in low temperature and high speed extrusion?

This may be due to scraping of the mold surface during filling and the initial laminar extrusion phase, resulting in strong mechanical scratches during subsequent extrusion.

11.2 Why are there still defects such as mechanical scratches in high temperature and low speed extrusion?

This may be due to the high temperature of the rod, which causes strong turbulence during extrusion, causing a large number of oxides and impurities on the ingot surface to flow towards the center, making the profile surface not good.

12. Mold

12.1 Combination molds are divided into two types according to their structure: bridge-type combination molds and corridor-type combination molds. Bridge-type combination molds are commonly known as tongue-shaped molds, while corridor-type combination molds are simply called combination molds.

12.2 Tongue-shaped molds require lower extrusion force and are suitable for extrusion of hollow alloy profiles that do not deform easily and have small internal holes.

12.3 Combination molds are suitable for extrusion of large and medium-sized hollow profiles, with complex shapes and larger internal cavity dimensions, made of alloys that are easily deformed.

12.4 Hollow profiles extruded in combined molds have evident welds in their macrostructure, and the number of welds is equal to the number of metallic strands into which the ingot is divided.

12.5 To obtain high quality welds, the pressure inside the mold must be increased and a slightly higher extrusion coefficient must be selected. It is advisable to use a higher extrusion temperature and the extrusion speed should not be too fast.

12.6 When inspecting hollow profiles, their surface quality, geometric dimensions, mechanical properties and internal structure are the same as ordinary profiles. However, for hollow profiles used in important parts, the welding quality should be inspected and the cutting length should not be less than 500-1000 mm.

13. Ingot Casting

13.1 Typical crystal structures of aluminum alloy ingots include thin crystalline bands on the surface, columnar crystalline bands, and equiaxed crystalline bands in the center.

13.2 In aluminum alloy ingots, there are three common shapes of aluminum solid solution grains:

The. Equiaxed crystals in granular shape

B. Columnar crystals in an elongated shape

w. Feathered crystals in a thin leaf shape.

13.3 Under constant alloy composition and other conditions, the width of the columnar region of the crystal increases with increasing casting temperature. The size of equiaxed grains decreases as the casting temperature decreases. When the casting temperature is constant, the columnar crystalline region decreases with increasing alloying element content.

13.4 Refining treatment: It is a process of increasing the dispersion of the metal or alloy structure and improving its organization with a small amount of special additives (refining agents). It is also called refinement treatment or incubation treatment.

14. Wall thickness technical requirements

14.1 Oxide wall thickness

The. Acid sand oxidation: ±0.1mm required

B. Silver-white oxidation: ±0.1 mm required

w. Polished oxidation: ±0.1mm required

d. Sandblasting oxidation: -0.08 to +0.1 mm required

It is. Twist pattern oxidation: -0.08 to +0.1 mm required

f. Alkaline attack oxidation: -0.05 to 0.15 mm required

14.2 Electrophoretic wall thickness

The. Flat electrophoresis: ±0.1mm required

B. Sandblast electrophoresis: ±0.1mm required

w. Color electrophoresis with alkaline etching: -0.05 to +0.1 mm required

14.3 Spray coating wall thickness

The. General spray coating: -0.15 to +0.05 mm required

B. Anti-wrinkle spray coating: -0.15 to +0.05 mm required

w. Woodgrain spray coating: -0.15 to +0.05 mm required

d. Fluorocarbon spray coating: -0.12 to +0.07 mm required

14.4 Export substrate wall thickness

The. The wall thickness tolerance specified in the drawing is carried out.

B. If wall thickness tolerance is not specified, national standard wall thickness tolerance column 2 will be performed.

w. For completely closed hollow profiles, national standard wall thickness tolerance column 3 is performed (except for SOMA series round tubes).

Note: The wall thickness tolerance marked on the drawing and production plan is the tolerance of the finished product. The wall thickness tolerance of the extruded substrate should be adjusted according to different surface treatment methods.

15. Key points for metallographic grinding

For aluminum, generally start with 0 grit sandpaper and then move up to 400#, 600#, 800#, 1000#, 1200#. During the grinding process, one type of sandpaper is used in one direction.

When moving to the next sandpaper, the sanding direction should be perpendicular to the previous one, which is beneficial to observe whether there are deep scratches from the previous sanding phase.

To prevent hard particles or large pieces of metal from coming loose during sanding, a thin layer of wax can be applied to the sandpaper. This makes grinding smooth and produces a better metallographic surface. When sanding, sit up straight and apply even force. The sample must be square and flat.

16. Electrolytic Polishing

H2SO4, HNO3 and HF are mixed and an L-shaped cathode made of stainless steel or aluminum plate is used. An appropriate voltage is selected according to the sample size. The voltage and polishing time must be strictly controlled during electrolytic polishing, generally around ten seconds.

After polishing, rinse with clean water, then ethanol, and then use dilute nitric acid to remove corrosion products from the surface, followed by rinsing with clean water and air drying.

17. High magnification electron metallographic microscope

The magnification can reach 1000 times. The coarse focus button is on the left and the fine focus button is on the right, on top of the horizontal mobile device and power button. There is a ruler on the right side eyepiece to accurately position the tissue and phase. The tracker on the right can be used directly for photography.

When processing photos, debris must generally be removed. Vibration of the bench or body during operation may cause observed and photographed phases to appear blurred. For tissue analysis, there are generally many dendrites in each grain and different amounts of precipitation are present at the grain boundaries. After etching the sample with mixed tristrong acid, the aluminum matrix appears as white, the precipitated phases appear as black-gray, and the grain boundaries appear as gray lines in the field of view.

18. Process Flowchart for Foundry

Input inspection → dosing → cold furnace preheating → charging furnace → melting → skimming → melting furnace sampling and testing → refining → holding furnace sampling and testing → refining skimming → retention → casting → inspection of round ingots → cut to size bar → sequencing

19. Grain Size Classification Standard

Grade 1, grain size ratio 1:1, average grain area 0.026 mm2

Grade 2, grain size ratio 1:1, average grain area 0.40 mm2

Grade 3, grain size ratio 1:1, average grain area 1.20 mm2

Grade 4, grain size ratio 1:1, average grain area 2.60 mm2

Grade 5, grain size ratio 1:1, average grain area 8.0 mm2

Grade 6, grain size ratio 1:1, average grain area 16mm2

Grade 7, grain size ratio 1:1, average grain area 36mm2

Grade 8, grain size ratio 1:1, average grain area 80mm2

20. Annex to the Foundry Process Supervision and Inspection System

Drain temperature: 735-770℃

Waiting time: 30-40min

Casting temperature: 715-745℃

Casting speed: diameter 80mm, 200-220mm/min

Casting speed: diameter 100mm, 180-200mm/min

Casting speed: diameter 120mm, 155-175mm/min

Casting speed: diameter 151 mm, 120-140 mm/min

Casting speed: diameter 174 mm, 95-115 mm/min

Casting speed: diameter 198 mm, 80-100 mm/min

Casting speed: diameter 275mm, 60-80mm/min

Casting speed: diameter 310mm, 60-75mm/min

Casting speed: diameter 370mm, 50-65mm/min

Casting speed: diameter 446mm, 40-55mm/min