Due to its versatility and unique properties, aluminum is suitable for applications that require excellent strength-to-weight ratio, good thermal/electrical conductivity and corrosion resistance. However, your project may require specific aluminum finishes to ensure parts meet your intended application and design requirements. Therefore, it is important to know the common types of aluminum finishes to choose the one that best suits your projects.

This article explains why your aluminum products need surface treatment, what types of surface treatments exist for aluminum, and what to consider when treating aluminum effectively. Let's start!

Why do you need surface finishing for your aluminum products?

Surface finishing is the most common application on aluminum products, as it affects the appearance, functionality and durability of the final product. Manufacturers often use different aluminum finishes to give parts a uniform, consistent coating in different colors.

These surface treatments for aluminum also improve electrical insulation properties, reflectivity and wear resistance. Aluminum coatings can also reduce friction between the aluminum surface and other surfaces, ensuring better overall performance of aluminum parts.

Furthermore, the surface treatment of aluminum is crucial to ensure the corrosion resistance of aluminum products. However, poorly manufactured aluminum products with gaps and cracks can attract moisture and other contaminants that can cause corrosion. Therefore, smooth and uniform aluminum surfaces prevent the build-up of contaminants that can negatively affect the surface of aluminum products.

10 types of aluminum surfaces

Product designers and manufacturers use different surface treatments for aluminum parts. There are different aluminum surfaces, each with unique properties and practical uses. Below are typical types of aluminum finishes.

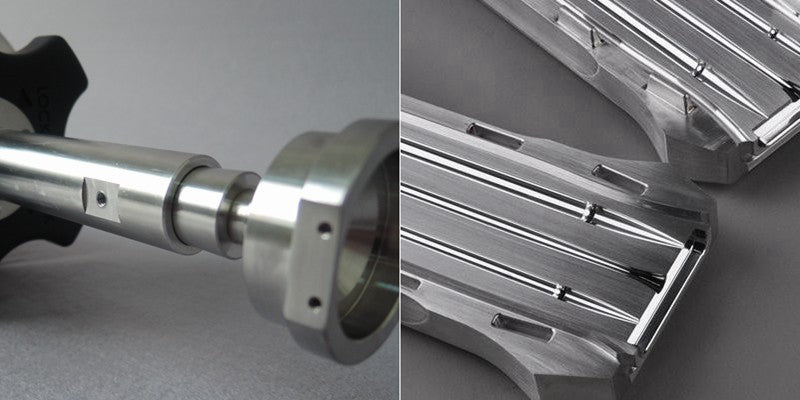

1. As a machined finish

The machined surface is the original condition of the machined aluminum part when it leaves the rolling mill. Surface finishing has no extra cost and is often used for applications where there are no mechanical or chemical requirements for surface finishing.

CNC machining of aluminum provides parts with a surface roughness range of Ra 0.2 – 3.2 µm, depending on application requirements. The machined aluminum surface conforms exactly to strict tolerances. However, your aluminum parts may have visible machine tool cut marks.

2. Anodizing

Anodizing is a commonly used surface treatment for aluminum profiles. It is an electrochemical process that transforms aluminum surfaces into a long-lasting, aesthetically pleasing and corrosion-resistant oxide layer. Furthermore, this aluminum finish offers different coating thicknesses to obtain the desired benefits.

In anodizing, existing aluminum is used to form a protective layer over the material. The oxide layer is firmly integrated into the aluminum material through a solid molecular connection.

Aluminum anodizing guarantees the longevity of aluminum products with excellent resistance to corrosion and wear. Additionally, anodizing aluminum provides better aesthetics because anodized parts can take on more vibrant color options and maintain their appearance for a longer period of time.

3. Powder coating

Powder coating is the perfect surface finish for aluminum if your products require a decorative and protective finish. As a rule, a protective layer is applied to the aluminum surface using an electrostatic process.

The dust particles are passed through a special gun, such as a corona gun, to give them a negative charge as they are applied to the grounded surface. This creates an electrical field between the electrostatic gun and the earthed aluminum component, which ensures that the sprayed powder adheres to the metal.

The aluminum and coating form a solid bond after curing. Powder coating is more environmentally friendly because, unlike wet paint, it contains no solvents. However, due to the visible structure of the granules used, it may have a slightly rough surface.

4. Alodine Finish (Chemical Film)

Alodine or Chem-Film finish is another aluminum surface finish suitable for passivating oxide films on aluminum product surfaces. The aluminum piece is immersed in a controlled chemical bath for a certain period of time while the Alodine film forms on its surface.

This surface treatment for aluminum is a more economical alternative to anodizing. Ensures greater corrosion resistance for machined aluminum parts. Although chemical film is not as hard or wear-resistant as anodized coating, it is suitable for certain applications that require high electrical conductivity.

5. Pearl blasting

Bead blasting is one of the most commonly used mechanical surface treatments for aluminum. A ball blaster is used to blast media such as steel balls or fine glass at high pressure onto the surfaces of aluminum products. The beads remove contaminants from the aluminum surface, leaving a smooth, shiny and clean surface.

This surface treatment usually gives your aluminum components a “satin” or “matte” finish. Bead blasting is one of the suitable aluminum surface options when your aluminum product needs a semi-polished and textured surface. This means your material maintains its base color and has a lighter surface finish.

6. Electroplating

Electroplating is a type of aluminum finishing in the manufacturing industry. A thin layer of metal is applied to the surface of another metal, for example aluminum, through electrolysis. The underlying material is the “substrate material,” while the added metal is called the “plating metal.” Typical examples of deposition materials that can be coated include copper, silver, gold, nickel, titanium, zinc and chromium.

The additional layer improves the chemical, mechanical and physical properties of aluminum materials, providing better electrical/thermal conductivity, strength and resistance to UV light, abrasion and corrosion. This allows you to add different metals to the aluminum surface to obtain the desired properties that suit the intended applications.

7. Polishing

Polishing aluminum is an ideal way to improve the aesthetics, functionality and longevity of your aluminum products. Metal polishing protects the surface of aluminum components against contamination and oxidation, although over time it is worn down by influences such as atmospheric oxygen, wear and tear and high temperatures. Creates a reflective surface to protect the aluminum surface from corrosive substances.

Due to its shiny appearance, polishing is suitable for custom aluminum parts. Typical applications of this aluminum surface treatment include medical device manufacturing, interior design, retail equipment, and restaurants.

8. Brushing

Brushing is a mechanical treatment of aluminum surfaces in which an abrasive brush is passed over an extruded aluminum surface. This process is also known as mechanical polishing. Brushing removes imperfections from the surface of aluminum and its alloys, creating unidirectional lines parallel to the direction of brushing on the surface.

This aluminum surface finish gives the aluminum metal a brushed appearance for increased scratch resistance and attractive aesthetics. Brushing as an aluminum surface treatment adds a touch of luxury to aluminum products. Brushed aluminum profiles are suitable for various indoor and outdoor aluminum components such as aluminum household appliances.

9. Laser engraving of aluminum

Aluminum laser engraving is an effective marking technique for creating deep, permanent markings or engravings on aluminum surfaces. Surface finishing provides precise results by directing a laser beam over the surface in a specific pattern to create detailed marks or cut it.

This aluminum surface treatment is used in various industries including aerospace, military, medical, tool manufacturing and automotive. Fiber lasers are the standard for engraving aluminum products because they provide quality markings exactly to design specifications.

10. Brilliant Immersion

Bright dipping is an aluminum finishing process used to polish aluminum parts to a high shine. Aluminum profiles are dipped in acid to create a mirror-like surface through microscopic fluctuations on the surface of the aluminum.

Certain aluminum products, such as food and beverage containers, may require a glossy finish due to their aesthetically pleasing finish. However, the chemicals used in this aluminum surface treatment present potential risks and are incompatible with all aluminum alloys. Therefore, it is best used with certain types of aluminum, such as 6463 aluminum alloy.

Different surface effects and styles for aluminum surfaces

Aluminum alloys can be highly customized depending on the requirements of the intended applications. Below are the different surface effects and styles of aluminum used by product designers.

gloss

A high gloss finish results in a smoother, more aesthetically pleasing surface with impressive light reflection. Glossy finishes are typically shiny, regardless of color.

Aluminum polishing is one of the standard aluminum surface treatment options to achieve that high-gloss effect on aluminum automotive parts, architectural elements and consumer electronics. However, dust, fingerprints and water stains may be more visible on glossy surfaces than on other aluminum surfaces.

Satin

Satin finishes provide a slightly shiny surface. Although they are less reflective than high-gloss surfaces, they are generally smoother than matte surfaces. Therefore, they are a suitable mid-range choice for aluminum parts without a preferred finish style. For example, the brushed finish provides a satin finish for furniture and architectural projects.

Satin finish typically has a gloss level of 72 GU. It perfectly hides flaws and is easy to clean. Plus, the satin finish won't leave fingerprints or water stains like a high-gloss finish.

Matte

This aluminum surface finish has a matte, non-reflective appearance with a gloss level of 30 GU. It hides water stains and fingerprints well and is more economical because it doesn't require many layers of coating. Surface treatments such as anodizing and powder coating can give aluminum parts and components a matte finish.

Matte surfaces are durable, stain resistant and easy to clean. Additionally, they may appear less polished than glossy or satin finishes because they are not shiny.

Metallic

A metallic finish gives aluminum products a luxurious feel. This aluminum surface has low reflection compared to a high gloss surface. Brushed or clear anodizing provides a metallic surface finish for aluminum products such as decorative metal parts, nameplates and signage.

You can also dye this metallic surface to make it look like brass, copper, gold, stainless steel and silver. Although metal surfaces are more likely to leave water stains and fingerprints, they are aesthetically pleasing and easy to clean.

Factors to Consider When Choosing an Aluminum Surface Coating

Aluminum finishing options are important for improving the function and aesthetics of machined parts. This section therefore explains useful considerations for selecting the appropriate aluminum surfaces for your products.

Intended application

Find out if the aluminum parts are intended for indoor or outdoor use. Outdoor aluminum products typically require a special surface treatment that resists UV radiation, corrosive substances and temperature fluctuations.

Furthermore, it would be useful to use an aluminum surface treatment, such as anodizing, electroplating or allodyning, that guarantees chemical resistance when the product is exposed to corrosive elements. You also need to determine whether the aluminum components are subject to significant wear, such as impact or abrasion.

Desired aesthetics

Consider the aesthetic requirements of your aluminum parts to determine the ideal aluminum surface finish that perfectly meets these requirements. Multiple aluminum surface options provide the look you want with a wide range of colors, textures and gloss levels.

For example, aluminum parts with a laminated surface often have a dull appearance with visible machining marks. However, you can give your CNC aluminum parts a mirror finish, such as by glossy dip. Likewise, some aluminum finishes may vary in color and texture depending on the needs of your projects. Therefore, examine the desired aesthetics of the intended application to select an appropriate surface finish.

Cost implications

It is wise to consider your budget when selecting an aluminum surface treatment for your products, as initial costs for aluminum surfaces vary significantly. So be sure to choose a finish that fits your project budget.

It's best to consider the total cost of ownership, maintenance, and likely parts replacement costs. However, choosing a more durable surface can help offset the high initial cost if it reduces long-term costs.

Durability and maintenance

It would be useful to evaluate the expected lifespan of aluminum components when selecting a finish that will provide the desired longevity. For example, you can extend the life of aluminum components through anodizing.

Additionally, it is best to determine the amount of maintenance a particular aluminum surface coating requires when selecting the right coating for your project. Aluminum surfaces, like powder coating, require little maintenance. Additionally, galvanized aluminum surfaces are easy to clean.

Do you need surface treatments for your aluminum parts?

In addition to our surface treatment expertise, we also offer reliable manufacturing processes such as CNC machining, 3D printing, die casting, rapid tooling, and sheet metal processing. Our team will work closely with you to understand your project requirements and ensure that production and surface treatments are carried out with precision and consistency. Contact us today!

Concluding

Although there are several options on the surface treatment table, aluminum surfaces are ideal for enhancing your product by improving aesthetics, quality and durability. Each aluminum surface treatment offers its advantages and is suitable for each aluminum profile. Furthermore, the choice of aluminum surface treatment determines the product's useful life, corrosion resistance and other factors that affect the functionality of its parts.

Common questions

Which aluminum surface treatment is best?

While each aluminum surface offers unique benefits, aluminum anodizing offers incredibly durable protection for your parts. It protects your aluminum products from corrosion and wear and ensures that they maintain their aesthetic appeal for longer.

Which surface finish is ideal for preventing rust on aluminum parts?

Various aluminum surface treatments, including anodizing, painting and any other surface treatment that forms a coating on the aluminum surface, are suitable for protecting the surface of aluminum parts from corrosion or rust.