STEEL IN THE BRAZILIAN INDUSTRY

Can aluminum be welded?

Welding characteristics of aluminum and aluminum alloy Aluminum is easily oxidized in air and during welding, and the aluminum oxide (Al2O3) generated has a high melting point, is very stable...

Can aluminum be welded?

Welding characteristics of aluminum and aluminum alloy Aluminum is easily oxidized in air and during welding, and the aluminum oxide (Al2O3) generated has a high melting point, is very stable...

Variable Polarity Plasma Arc Welding: Exploring...

Principle and development Variable polarity plasma arc welding (VPPAW), that is, asymmetric square wave AC plasma arc welding, is a new efficient welding process developed...

Variable Polarity Plasma Arc Welding: Exploring...

Principle and development Variable polarity plasma arc welding (VPPAW), that is, asymmetric square wave AC plasma arc welding, is a new efficient welding process developed...

6 New advanced welding technologies

1. Laser welding Laser radiation heats the surface to be machined and the heat is directed to internal diffusion through heat transfer. By controlling the laser pulse width, the...

6 New advanced welding technologies

1. Laser welding Laser radiation heats the surface to be machined and the heat is directed to internal diffusion through heat transfer. By controlling the laser pulse width, the...

10 Essential Welding Techniques: A Comprehensiv...

1. Electrode arc welding (1) Arc welding Arc is a persistent and intense gas discharge phenomenon that occurs between two charged conductors. Arcing (1) Short circuit between...

10 Essential Welding Techniques: A Comprehensiv...

1. Electrode arc welding (1) Arc welding Arc is a persistent and intense gas discharge phenomenon that occurs between two charged conductors. Arcing (1) Short circuit between...

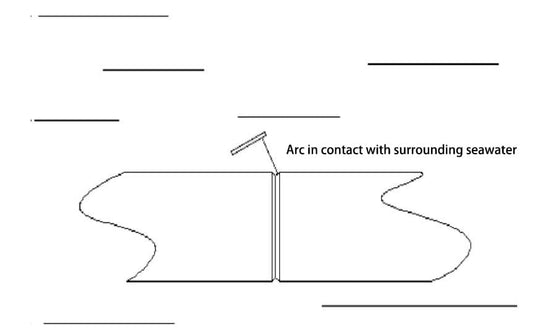

Revolutionizing underwater welding: advances an...

1. Introduction Due to the difficult working environment in the ocean, marine engineering structures are exposed to various challenges, including structural loads, storms, waves, tidal forces,...

Revolutionizing underwater welding: advances an...

1. Introduction Due to the difficult working environment in the ocean, marine engineering structures are exposed to various challenges, including structural loads, storms, waves, tidal forces,...

Top 10 Electric Welding Machine Manufacturers a...

Electric welding machines play a crucial role in several industries, including construction, automotive, aerospace, and many others. The manufacturers of these machines understand the importance of...

Top 10 Electric Welding Machine Manufacturers a...

Electric welding machines play a crucial role in several industries, including construction, automotive, aerospace, and many others. The manufacturers of these machines understand the importance of...