STEEL IN THE BRAZILIAN INDUSTRY

Table of Physical, Chemical and Mechanical Prop...

Chemical Composition of Stainless Steel Category Note Chemical composition (%) KS (JIS) C Cr No Mo Others Austenitic 301 ≤0.15 16.0~18.0 6:00 ~ 8:00 – – 301L ≤0.030 16.0~18.0 6:00...

Table of Physical, Chemical and Mechanical Prop...

Chemical Composition of Stainless Steel Category Note Chemical composition (%) KS (JIS) C Cr No Mo Others Austenitic 301 ≤0.15 16.0~18.0 6:00 ~ 8:00 – – 301L ≤0.030 16.0~18.0 6:00...

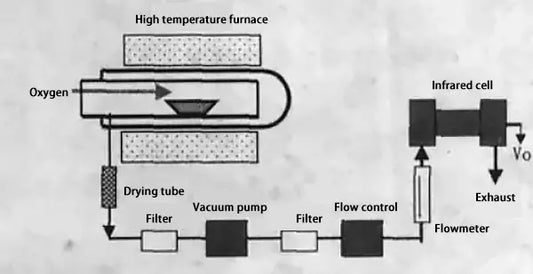

Heat Treatment of 304 Stainless Steel Pipes: Ex...

The objective of annealing is to eliminate structural defects, improve the homogeneity of the composition and refine the grains, improving the mechanical properties of the steel and reducing residual stresses....

Heat Treatment of 304 Stainless Steel Pipes: Ex...

The objective of annealing is to eliminate structural defects, improve the homogeneity of the composition and refine the grains, improving the mechanical properties of the steel and reducing residual stresses....

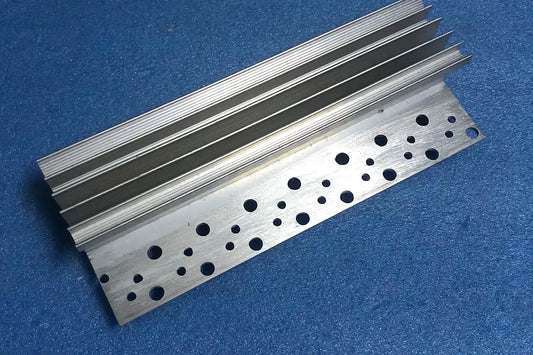

Thermal conductivity chart of aluminum profiles

Regarding the thermal conductivity coefficients of various aluminum profiles, the thermal conductivity coefficient of extruded aluminum is as follows: Name Model Thermal conductivity (S/m·...

Thermal conductivity chart of aluminum profiles

Regarding the thermal conductivity coefficients of various aluminum profiles, the thermal conductivity coefficient of extruded aluminum is as follows: Name Model Thermal conductivity (S/m·...

Chemical and Mechanical Properties of SUS 316L,...

Chemical composition: (Unit: wt%) Specification C Si Mn PS Cr No Others SUS316 ≤0.08 ≤1.00 ≤2.00 ≤0.045 ≤0.030 16.0~18.0 10.0~14.0 Sec : 2~3 SUS316L ≤0.03 ≤1.00 ≤2.00 ≤0.045 ≤0.030 16.0~18.0...

Chemical and Mechanical Properties of SUS 316L,...

Chemical composition: (Unit: wt%) Specification C Si Mn PS Cr No Others SUS316 ≤0.08 ≤1.00 ≤2.00 ≤0.045 ≤0.030 16.0~18.0 10.0~14.0 Sec : 2~3 SUS316L ≤0.03 ≤1.00 ≤2.00 ≤0.045 ≤0.030 16.0~18.0...

Stainless Steel Passivation Techniques Explained

Therefore, the commonly used procedure is as follows: A. Pre-cleaning/degreasing B. Primary Cleaning C. Acid washing D. Secondary Cleaning E. Passivation/Decontamination F. Cleaning and Drying...

Stainless Steel Passivation Techniques Explained

Therefore, the commonly used procedure is as follows: A. Pre-cleaning/degreasing B. Primary Cleaning C. Acid washing D. Secondary Cleaning E. Passivation/Decontamination F. Cleaning and Drying...