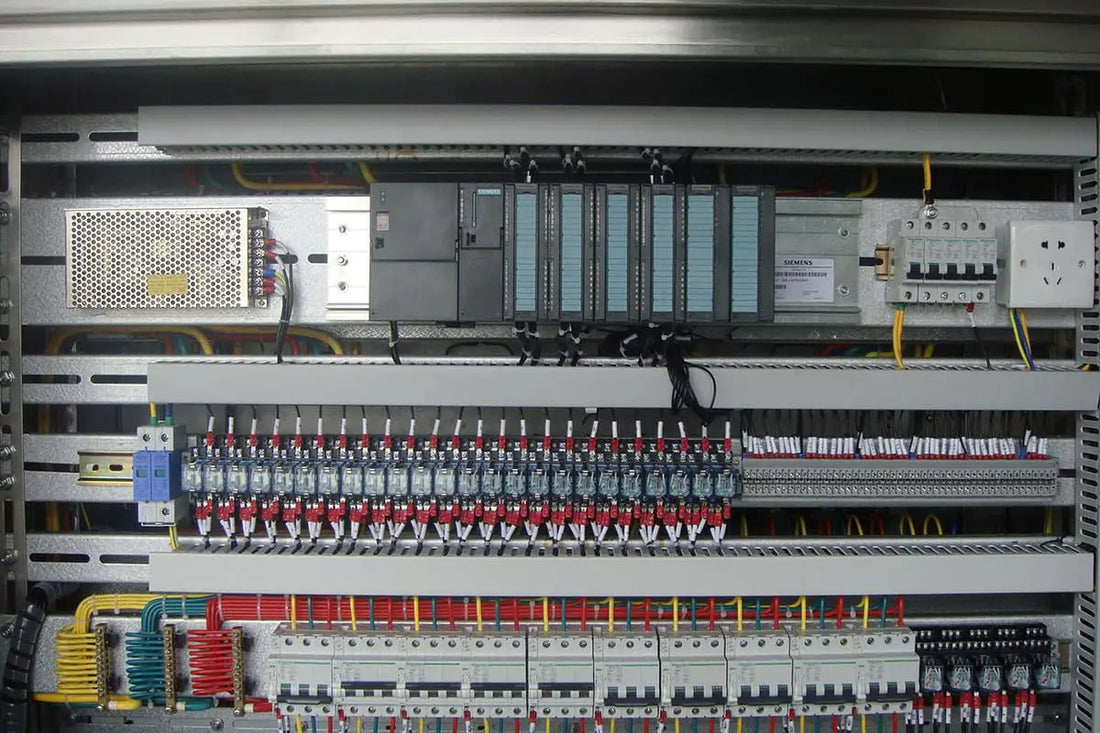

I. PLC Inputs and Outputs

A small programmable logic controller (PLC) flexibly controls a complex system. What you see are staggered rows of input and output relay terminal blocks, corresponding indicator lights, and PLC numbers, like an integrated circuit with dozens of legs.

Without a schematic, anyone would be powerless in troubleshooting equipment, resulting in a significant slowdown in fault detection.

Therefore, we created a graphic based on the electrical diagram, posted on the control panel or equipment cabinet, indicating the input and output terminal number of each PLC, its corresponding electrical symbol and its name, similar to the description of the function of each pin on an integrated circuit. With this input-output chart, electricians familiar with the operating process or equipment ladder diagram can begin troubleshooting.

For those who are not familiar with the operation process or cannot read ladder diagrams, an additional graphic is needed: the PLC input-output logic function table. This table demonstrates the logical correspondence of most input circuits (trigger elements, associated elements) and output circuits (execution elements) during the operation process.

Experience shows that if you are proficient in using the input-output correspondence table and the input-output logic function table, you can easily troubleshoot electrical faults without a schematic.

PLC Basic Logic Instructions

| To describe | Mitsubishi | Siemens | OMROM |

| Charging, normally open contact at the beginning of the circuit | L.D. | L.D. | L.D. |

| Reverse charging, normally closed contact at the beginning of the circuit | LDI | LDN | NO |

| E, normally open contact | AND | A | AND |

| Reverse and normally closed contact | ANI | ONE | AND NOT |

| Or normally open contact | OR | 0 | OR |

| Reverse or normally closed contact | ORI | ABOUT | OR NOT |

| Block and | ANB | ALD | And L.D. |

| Block or | BALL | OLD | OR LD |

| Exit | OUTSIDE | = | OUTSIDE |

| To deny | INV | NO | NO |

II. Input circuit troubleshooting

To determine the condition of a button, limit switch, line, or other input circuit, you can press the button (or other input contact) while the PLC is energized (preferably in a non-operating state to avoid unintended operation of the equipment). .

The PLC input light corresponding to the button should light up, indicating that the button and line are operating normally. If the light does not come on, the button may be defective, the line may have poor contact, or there may be a broken wire.

III. Output circuit troubleshooting

For PLC output points (considering relay output types here), if the corresponding actuator indicator light does not light up despite the PLC being in operation, this indicates that the PLC input-output logic function for this actuator has not been activated. satisfied, suggesting a fault in the input circuit.

If the corresponding indicator light is on but the corresponding actuator such as a solenoid valve or contactor does not work, first check the solenoid valve control power and fuse.

If the tester light does not illuminate when measuring the common terminal of the corresponding PLC output point, there may be a power failure such as a blown fuse.

If the tester light comes on, the power supply is fine, suggesting a fault in the corresponding solenoid valve, contactor or line.

After ruling out faults in the solenoid valve, contactor or line and finding that the system is still not operating normally, use a multimeter to connect one probe to the corresponding output common terminal and the other to the corresponding PLC output point.

If the solenoid valve still does not work, this indicates a fault in the output line. If the solenoid valve works, the problem is at the PLC output point.

Given that a test pen can sometimes give false readings, an alternative method of analysis could be to measure the voltage between the PLC output point and the common end using a multimeter. If the voltage is zero or close to zero, it suggests that the PLC output point is operating normally and the fault is external.

If the voltage is relatively high, it indicates that the contact resistance of this point is too high and has been damaged. Furthermore, when the indicator light does not come on, but the corresponding solenoid valve or contactor is activated, it is possible that this output point has been welded due to an overload or short circuit.

At this point, the wires connected to this output point should be removed and the resistance between the output point and the common end should be measured using the multimeter's resistance setting. If the resistance is low, this suggests that this contact point is damaged. If the resistance is infinitely high, it means the contact point is good and the corresponding output indicator light is likely defective.

4. Program Logic Inference

There are many types of PLCs commonly used in industry. For low-cost PLCs, the ladder diagram instructions are basically the same. For mid- to high-end machines like the S7-300, many programs are written in lists of instructions.

Practical ladder diagrams should have symbolic annotations; otherwise, reading becomes difficult. Understanding the process or equipment operation before looking at the ladder diagram makes everything easier.

When analyzing an electrical fault, the backtracking or reverse deduction method is generally used, that is, starting from the fault point, finding the corresponding PLC output relay and starting to backtrack the logical relations that satisfy its operation. .

Experience suggests that once a problem is found, the fault is usually corrected, as it is rare for multiple faults to occur simultaneously.

V. Determination of Faults Inherent to the PLC

Typically, PLCs are extremely reliable devices with a low failure rate. However, external factors may cause the PLC to malfunction. An incident occurred with a 220V powered proximity switch. The two signal input cables of the PLC and the 220V power line of the proximity switch shared a four-core cable. When the switch failed, the electrician replaced it, but mistakenly switched the neutral supply line with the PLC input common line, leading to three PLC input points on the power supply burning out.

In another case, the neutral line of the system's power transformer was interrupted due to corrosion, causing the PLC's 220V supply to rise to 380V. This damaged the power module at the base of the PLC. This was later corrected by the addition of a 380/220 V isolation control transformer. The common output ends of the Siemens S7-200 PLC are labeled 1L, 2L, etc., with the running computer represented as AC1N and the +24V power supply as L+M. This categorization can easily confuse beginners or those with less experience. Misinterpreting the L+M as a 220V power terminal can instantly burn out the PLC's 24V power supply.

The odds of malfunctioning hardware components such as PLCs and CPUs, or missing software, are virtually negligible. Likewise, unless subjected to strong electrical intrusion, PLC input points are unlikely to fail. The normally open points of the PLC output relays, barring peripheral load short circuits or improper design that allows the load current to exceed its rated range, have a long service life.

Therefore, when troubleshooting electrical faults, the focus should mainly be on the peripheral electrical components of the PLC. Instead of constantly suspecting problems with PLC hardware or software, this approach is crucial for quickly repairing faulty equipment and quickly resuming production. Therefore, the emphasis in resolving electrical faults in PLC control circuits is not on the PLC itself, but on the peripheral electrical components within the circuits controlled by the PLC.