THIS is the meaning of ventilation

To make the indoor concentration of pollutants meet relevant standards.

II. Main sources of pollutants

In the human-dominated indoor environment, the main pollutants are.

- Carbon dioxide from human metabolism and metabolites from the skin surface;

- Harmful substances emitted by building materials, such as benzene, aldehydes and other organic substances;

- Radioactive substances such as radon in the surrounding soil;

- Dust and sulfur dioxide in outdoor air.

III. Ventilation system types

Base: The energy source of air.

(1 ) Natural ventilation system

Natural ventilation uses the difference in pressure caused by temperature (actually the difference in air density) or wind, to allow the exchange of air between indoor and outdoor environments, thus improving indoor air quality. It is an economical and effective ventilation method for workshops with high residual heat. Since it does not require additional power equipment, it is a sustainable solution.

However, natural ventilation has some limitations. It cannot regulate the quality of the outside air entering the indoor space or purify the polluted air discharged from the inside to the outside. Furthermore, its effectiveness depends on outdoor weather conditions, which can lead to inconsistent ventilation results.

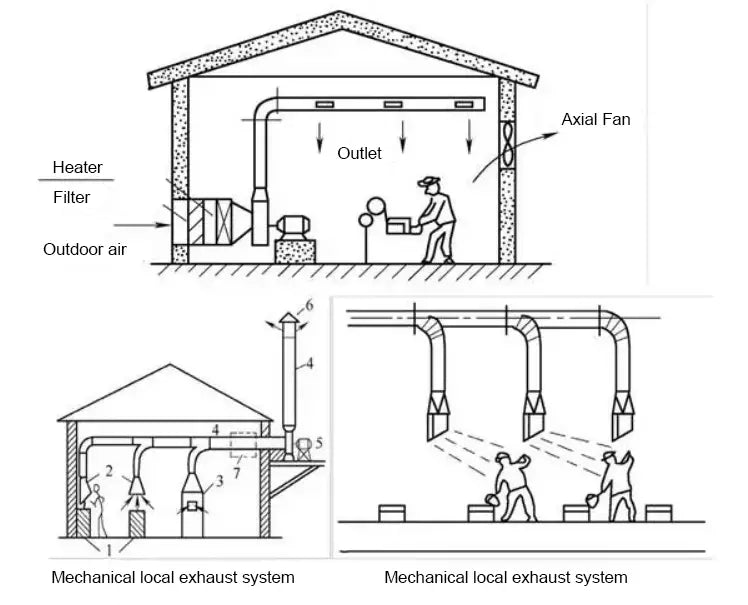

( 2 ) Mechanical ventilation system

The method of using a mechanical fan to create airflow and improve indoor air quality is called mechanical ventilation. With this method, air volume and pressure can be adjusted as needed, ensuring adequate ventilation and allowing control of the direction and speed of airflow in the room.

Additionally, the incoming and exhaust air can be treated to ensure that the air in the room meets the required parameters. As a result, mechanical ventilation is a widely used method.

N natural ventilation system

The working principle of natural ventilation

For a building or room, if it has two openings (doors or windows, etc.) and the air pressure on both sides of each opening is not the same, then air flows into each opening under the effect of pressure difference.

Natural ventilation under external wind pressure:

Mechanical ventilation system

- General ventilation

1) Principle: General ventilation serves to ventilate the entire room.

The basic principle is to dilute the concentration of harmful substances in indoor air with clean air and continuously discharge polluted air to the outside, while ensuring that the indoor environment meets hygiene standards.

General ventilation is also known as dilution ventilation.

Location of air supply and exhaust openings for general ventilation :

When designing a comprehensive ventilation system, one basic principle must be observed: clean air must be sent directly to the personnel location or to a location with a low level of pollutants.

Common air delivery and exhaust types include top delivery with top exhaust, bottom delivery with top exhaust, mid delivery and dual exhaust, etc.

For specific applications, the following principles must be followed:

- The air intake must be located upwind of the exhaust outlet;

- The air intake must be located close to the personnel area or in an area with a low concentration of pollutants;

- Exhaust openings must be located in areas with a high concentration of pollutants;

- Throughout the controlled space, efforts must be made to standardize indoor airflow and reduce the existence of stray currents to prevent the accumulation of pollutants in local areas.

- Local ventilation

(1) Principle: Local ventilation is divided into local air intake and local exhaust, its basic principle is to control the local air flow, so that the local working area is not polluted by harmful substances, and create an air environment that meets the requirements.

Theoretical mechanism of construction and natural ventilation

The pressure distribution on the exterior surface of the building is the driving force, while the characteristics of individual openings determine the resistance to flow.

In terms of natural ventilation, there are two main reasons for air movement in buildings: wind pressure and temperature-induced buoyancy (which creates a density difference between indoor and outdoor air).

These two factors can work alone or together.

- Natural ventilation under wind pressure

The formation of wind is due to the difference in pressure in the atmosphere. When the wind encounters obstacles in its path, such as trees and buildings, it converts its dynamic pressure into static pressure, creating positive pressure (about 0.5-0.8 times the dynamic pressure of the wind speed) on the windward side and negative pressure (about 0.3 -0.4 times the dynamic pressure of the wind speed) on the leeward side.

The pressure difference that occurs as it passes through the building causes air to flow into the room through the windows and other openings on the windward side, while the internal air is discharged through the opening on the leeward side, forming a natural vent that provides full ventilation.

Wind pressure around a building is affected by the geometric shape of the building, its position relative to the wind direction, wind speed, and the natural topography around the building.

- Natural ventilation under thermal pressure

Hot pressing is caused by the difference in temperature between indoor and outdoor air, known as the “chimney effect”.

As a result of the temperature difference, a density difference is created between the inside and outside and a pressure gradient is created along the vertical direction of the building wall.

If the indoor temperature is higher than the outdoor temperature, there will be a higher pressure at the top of the building and a lower pressure at the bottom of the building.

When there are holes in these locations, air enters through the lower opening and exits through the upper part.

If the indoor temperature is lower than the outdoor temperature, airflow will occur in the opposite direction.

The amount of hot pressing depends on the difference in height between the two openings and the difference in air density between the inside and outside.

In practice, architects often use chimneys, ventilation towers, courtyard atriums and other ways to provide favorable conditions for the use of natural ventilation, so that the building can have good ventilation.

- Natural ventilation under a combination of wind and hot pressures

Natural ventilation in current buildings is the result of the joint action of wind pressure and hot pressure, but each has its strengths and weaknesses.

Wind pressure is influenced by weather, external wind direction, building shape, surrounding environment and other factors. Therefore, the joint action of wind pressure and hot pressure is not a simple linear superposition.

Architects must take into account all factors to make wind pressure and hot pressure complement each other and work closely together to achieve effective natural ventilation in the building.

- Mechanically assisted natural ventilation

In some large buildings, natural ventilation may not be sufficient to achieve adequate airflow due to long ventilation paths and high flow resistance. Furthermore, in cities with severe air and noise pollution, relying exclusively on natural ventilation can lead to the introduction of polluted air and noise into indoor spaces, which can harm human health.

To solve these problems, mechanically assisted natural ventilation systems are often used. These systems include a full suite of air circulation channels along with air treatment methods aligned with ecological principles such as ground pre-cooling, pre-heating and deep water heat exchange. These methods help to speed up internal ventilation with the help of certain mechanical techniques.

Ventilation system equipment and components

Natural ventilation systems typically do not require any equipment. In contrast, mechanical ventilation systems rely on a variety of equipment, including fans, air ducts, air valves, tuyeres, and dust removal equipment, among others.

I. Fan:

- The role of the fan in the duct: air transport.

- The basic structure of the fan: impeller, motor and housing.

- Types of fans:

- 1) Centrifugal fan;

- 2) Axial fan;

- 3) Mixed flow fan.

Centrifugal fan: used for low or high pressure air supply systems, especially low noise and high pressure systems.

There are four types of impeller blades: aerodynamic blades, backward-curved blades, forward-curved blades, and radial blades.

Fans in comfort air conditioners typically use centrifugal fans.

Four impeller designs make up the four basic shapes of a wind turbine :

(1) Backward blade fan: Backward curved straight blade, curved blade or winged blade.

- Backward-curved straight blade: a single straight metal.

- Backward curved blade: curved metal blade

- Winged Blade: Double-layer metal blades increase airflow efficiency through the impeller.

It is mainly used for operational investment savings that may be greater than the initial investment.

(2) The fourth type is the forward curved blade, which has a single-layer curved metal blade.

Four types of impeller

Forward-curved impellers versus backward-curved impellers

(1) Forward curved impeller

The turbine is made up of a large number of small, lightweight blades and other lightweight materials. These materials are even lighter than winged impellers. One advantage of forward-facing fans is that they can move more air at a lower speed compared to rear-facing fans of the same diameter, depending on the design.

Additionally, any rear-facing fan can operate at half the speed of a forward-facing fan to deliver the same volume of air. Consequently, the forward curved fan is a good choice for low to medium pressure operations due to its lower noise levels and affordable price.

(2) Backwards curved impeller

The backward curved fan is more efficient than the forward curved fan under large capacity and high differential pressure, making it a popular choice for medium pressure operations.

Two typical fan impellers

Axial fan:

The structure of an axial fan is illustrated in the figure. The impeller comprises a wheel with riveted blades, where the blades are mounted at an angle to the plane of the wheel. The blade type can be an airfoil twisted blade or a straight blade, as well as a twisted blade of equal thickness or a straight blade.

Axial fans are characterized by their small size, ease of maintenance, low air pressure and high air volume. They are often used in large air volume systems with low resistance.

Schematic diagram of the axial fan structure

Small site area, easy maintenance, lower air pressure, larger air volume, which is mainly used in large air volume systems with low resistance.

(3) Mixed flow fan

It concentrates the characteristics of centrifugal fan with high pressure and axial flow.

(4) Common fans for building

A high temperature smoke extraction and control fan can be used for daily ventilation under normal conditions. In case of fire, it extracts high temperature internal combustion gases to improve internal air circulation.

This fan is designed with high temperature resistance and is suitable for ventilation and smoke extraction in high-rise buildings, furnaces, garages, tunnels, subways, underground shopping malls and other similar environments.

D diagonal fan

This series of fans can be classified into single-speed and dual-speed fans. They are characterized by their compact structure, small size and ease of maintenance, among other benefits.

Based on specific needs, the installation angle, number of blades, rotation speed and other factors can be modified to meet various requirements.

Ceiling and sidewall fans can be classified as ordinary centrifugal fans and low noise centrifugal fans. They are used to exchange air in various places such as workshops, warehouses, skyscrapers, laboratories, theaters, hotels and hospitals, among others.

Air conditioning fan: Centrifugal air conditioning fan has the advantages of large performance and application range, low noise, light weight, convenient installation and reliable operation.

It can be combined with combined air conditioning units of various air conditioning plants.

Cabinet smoke extractor

II. air duct

- Shape: round and rectangular;

- Material: brick and concrete; thin steel sheet; fiberglass board; aluminum polyvinyl chloride plate; hose material.

III. Partial components

- Ar d product supports

(1) Function: anti-vibration, load-bearing;

(2) Shape: air duct connection and support: fixed and non-fixed.

Support support methods: brackets, hangers and brackets.

- Elbow

Right angle elbow and arc elbow: to change the direction of airflow.

- (a) Double blade

- (b) Single blade

- T ee : mixing t-shirt ; derivation t-shirt

- Ipe reducer

1) Sudden expansion and contraction: a change in wind volume. (See left figure below)

2) Gradient tube: change in air flow. (See right figure below)

- Air Duct Valves

- Regulate the air flow, open or turn off the wind system: butterfly valve, opposing multi-blade damper, 3-way regulating valve;

- Fire damper: in case of fire, cut off the airflow path, which prevents the fire from spreading through the air ducts;

(3) Check valve: to prevent air flow reversal after the fan stops.

Precautions in air duct system design:

- Air duct layout

The layout of air ducts must be straight to avoid complicated components such as elbows and tees. Connections to the air duct must be made in such a way as to reduce resistance and noise.

The air duct must be equipped with the necessary adjustment and measuring devices or have reserved interfaces for such devices.

Adjusting and measuring devices must be located in places convenient for operation and observation.

- The cross-sectional shape of the air duct

In the same area, the resistance of the circular duct is less than that of the rectangular duct.

When the rectangular duct is designed, the ratio of long and short sides is less than 3.0.

- The layout of the fan inlet and outlet

The inlet and outlet connecting tube of a fan has a significant impact on the fan's performance. Improper design of the connecting pipe can cause significant pressure loss and reduce air volume.

The dynamic air pressure at the inlet and outlet is high, so the piping design must consider this issue.

1) The distance from the inside of the duct bend or elbow to the fan inlet must be greater than the diameter of the fan inlet. This ensures uniform airflow across the fan impeller.

When the turning radius of curvature is not sufficient, deflector vanes must be added to the tube curves, as shown in the figure below.

2) When the air duct enters the fan with changed diameter, the requirement (cierta) is shown in the figure below and generally should be ≤45°, ≤30° is even better.

3) For dual inlet fans, it is necessary to ensure B≥1.25D, as shown in the figure below.

4) The rotation near the fan outlet must be consistent with the rotation direction of the fan impeller to make the air flow unobstructed and uniform and avoid unnecessary energy losses.

5) There must be a straight pipe section with a diameter of less than 3D (D is the diameter of the fan inlet) from the fan outlet to the bend to avoid unnecessary loss of static pressure.

6) Flexible joint should be added at the fan inlet and outlet to reduce the influence of vibration; The flexible joint material should be artificial leather or canvas.

- Tuyère location

The air inlet is the entrance to the ventilation and air conditioning system for collecting fresh air from outside, and its location must meet the following requirements:

(1) Must be located in an area with clean outdoor air.

(2) To prevent exhaust air from being sucked back into the system, the air inlet must be located on the windward side of the exhaust air outlet and below the exhaust air outlet.

(3) The distance between the bottom of the air inlet and the external ground generally should not be less than 2 cm to avoid inhaling ground dust.

(4) For refrigeration systems, the air inlet should be located on the outer wall with the sun at the rear.

Dust removal equipment

To prevent air pollution, the exhaust system must be purified before discharging air into the atmosphere to separate dust from the air.

The equipment used for this treatment process is called dust removal equipment, which comes in several types, including baffle dust collectors, cyclone dust collectors, bag-type dust collectors, spray tower dust collectors, and dust collectors. electrical powder.

F waterproofing and smoke exhaustion

To prevent the spread of fires and hazards, tall buildings must have fire and smoke exhaust designs.

The objective of fire prevention is to prevent the spread of fire and extinguish it.

The purpose of smoke exhaustion is to eliminate smoke from the fire in a timely manner, preventing the smoke from spreading outside and ensuring a successful evacuation for the occupants inside.

In the design of fire protection and smoke exhaustion in a high-rise building, the building is generally divided into several fire and smoke partitions, which are separated by firewalls and fire doors to prevent the spread of fire and smoke from one partition to another.

Smoke diffusion mechanisms

Smoke refers to the floating state of solid and liquid particles in the air resulting from the incomplete combustion of substances. The flow and diffusion of smoke are mainly influenced by factors such as wind pressure and thermal pressure.

Wind pressure is generated when wind blows on the outer surface of a building, hindering airflow, reducing speed and transforming kinetic energy into static pressure. On the windward side, the external pressure is greater than the internal pressure and air permeates from the outside to the inside. During a fire, if a window is on the windward side of a building, the effect of wind pressure can quickly spread smoke throughout the floor and even to other floors.

The stack effect, or hot pressure, is created by the difference in density between indoor and outdoor air and the height of the air column. The effect increases with the difference in temperature between inside and outside and with the height of the well.

When a fire occurs in a high-rise building, the temperature inside is much higher than the temperature outside. The height of the building shaft amplifies the hot pressure, causing smoke to spread upward along the building shaft. The chimney effect is more pronounced on the lower floors.

When a fire occurs at the bottom of a building or in a windward room, the effects of wind pressure and thermal pressure can make the fire more damaging than at the top of the building or in a leeward room.

During a fire, the power provided by the air conditioning system fans and the stack effect created by the vertical ducts can cause smoke and fire to spread along the ducts, quickly reaching as far as the ducts reach.

Therefore, high-rise buildings must adopt various smoke prevention and exhaustion methods, such as natural and mechanical exhaustion, to prevent smoke from spreading into the evacuation passages and ensure safety. The building's ventilation and air conditioning systems must also adopt fire and smoke prevention measures.

Ways of building fire and smoke exhaust:

- Natural smoke exhaust

Natural smoke exhaustion is a method that uses wind and hot pressure as energy. It has the advantages of simple structure, energy saving and high operational reliability.

In high-rise buildings, smoke-resistant staircases, front rooms against external walls, fire elevator front rooms and shared front rooms should adopt natural smoke exhaust methods.

The smoke outlet must be located in the lee of the prevailing wind direction in the building throughout the year.

- Mechanical smoke prevention

Mechanical smoke prevention is a technology that uses a mechanical supply of pressurized air to control the direction of flue gas flow by the gas flow and pressure difference generated by a fan.

When a fire occurs, the pressure difference caused by the fan's airflow prevents smoke from entering the building's safe evacuation passage, ensuring evacuation and firefighting needs.

For non-spreading balconies and corridors, smoke-proof staircases, front rooms with different orientations capable of opening external windows, front rooms with fire elevators and shared front rooms, mechanical smoke prevention installations should be provided.

When the refuge floor is completely enclosed, pressurized air supply facilities shall be provided.

- Mechanical exhaust:

Mechanical exhaust is a method that uses gas flow and pressure difference generated by a fan to exhaust combustion gases or dilute the concentration of combustion gases using an exhaust pipe.

The mechanical exhaust method is suitable for indoor walkways, rooms, atriums and basements that do not have natural exhaust conditions or where natural exhaust is difficult to achieve.

It must be designed and constructed strictly in accordance with mechanical exhaust requirements such as exhaust port configuration, exhaust fan selection and air duct material selection.

Mechanical smoke exhaust system control procedures can be divided into two types: fire control room and fire control room.

- Fire protection of ventilation and air conditioning systems

After a fire occurs, it is necessary to control the spread of fire to other fire compartments.

Therefore, fire dampers must be installed in the ventilation ducts of the ventilation and air conditioning system, and certain fire prevention measures must be taken.

The fire damper must be adjusted to:

- The dividing wall of the crossing fire compartment;

- Pass through engine rooms and important rooms or partitions and slabs of rooms at risk of fire;

- Junction of horizontal ducts connected to vertical ducts;

- The sides of cross deformation joints

The operating temperature of the fire damper is 70°C.

Pipes, thermal insulation materials, noise-absorbing materials and adhesives used in ventilation and air conditioning pipeline engineering must be made of non-combustible or non-combustible materials.

Equipment and components for fire and smoke prevention:

It mainly includes fire dampers, smoke exhaust valves and smoke exhaust fans.

- Fire damper

Fire dampers can be controlled by thermal components, smoke-sensing thermostats, and composite controls.

When a fuse ring is used, it will melt and fall in case of fire, and the valve will close due to spring force or self-gravity.

By using thermistors, thermocouples, bimetals and other components, a micromotor controlled by sensors and electronic components will close the valve.

The electromagnet and motor action of the control actuator or pneumatic control actuator can close the valve under the action of spring force or close the valve by motor rotation.

The fire damper valve closing drive mode has four types:

- Gravity

- Spring driven (or electromagnetic) force

- Engine powered

- Pneumatic drive

Commonly used fire dampers are:

- Gravity Fire Damper

- spring buffer

- Spring Fire Control Valve

- Fire Fan

- Pneumatic fire damper

- Electric fire damper

- Electronic self-control smoke

Temperature fuse structure

- F fire damper

Installed in the smoke exhaust system, the valve is usually closed.

When a fire occurs, a signal from the control center will activate the actuator to open the valve using spring force or motor torque.

The smoke exhaust valve with temperature sensing device will be activated when the fire temperature reaches the operating temperature. The valve will then close under the action of spring force to prevent the fire from spreading along the exhaust duct.

Smoke evacuation valves can be divided as follows :

- According to the control mode, there are two types: electromagnetic type and electrical type;

- According to the type of structure, it can be divided into decorative smoke evacuation valve, flap smoke evacuation valve, smoke evacuation and fire damper;

- According to the type of structure, it can be divided into decorative smoke outlet, flap smoke outlet, smoke outlet and fire outlet;

- According to the shape, it can be divided into rectangle and round valves.

- Anti-smoke fan

The smoke exhaust fan can use a general purpose fan or a special fan designed for fire and smoke exhaust.

When the smoke temperature is low, the fan may run for a long time. When the smoke temperature is high, the fan can operate continuously for a fixed time and generally has more than two degrees of rotation speed.

Special fans commonly used for fire and smoke exhaust include HTF series, ZW series, WX series and other types.