An Automatic Lubrication System (ALS), often referred to as a centralized lubrication system, is a system that delivers a controlled amount of lubricant (grease or oil) at specific times to various locations on a machine while the machine is operating. This system is more precise and eliminates the cycle of over-lubrication and under-lubrication that contributes to bearing failure.

The automatic lubrication system generally comprises the following elements.

(a) Controller or timer: Activates the lubrication distribution system and can be linked to a POS system.

(b) Pump with reservoir: It is used to store and deliver the lubricant to the system.

(c) Metering valves / Injectors -. It is a component that doses/dispenses the lubricant to the application points.

(d) Supply lines: It is a pipe that connects the pump to the dosing valves or injectors. The lubricant is pumped through these valves or injectors.

(e) Supply lines: It is a pipe that connects the dosing valves or injectors to the application points.

Reason for automatic lubrication system:

Whether the equipment is stationary, such as in a manufacturing facility, or mobile, such as trucks, mining or construction equipment, the application of lubricant is often most effective when it is dispensed in small, measured quantities at short, frequent intervals of time. However,

Time and human resource constraints, or sometimes physical location or type of machine, often make this approach to lubrication impossible. As a result, production cycles, availability of machines and labor determine the intervals at which machines are lubricated, which is not ideal for the point requiring lubrication. Automatic lubrication systems are installed in machines to solve this problem.

Benefits of the automatic lubrication system:

- All critical components are lubricated regardless of location or ease of access

- Lubrication occurs while the machinery is in operation, causing the lubricant to be evenly distributed within the bearing and increasing machine availability.

- Proper lubrication of critical components ensures safe operation of machinery.

- Less component wear means longer component life*, fewer breakdowns, reduced downtime, reduced replacement costs and reduced maintenance costs.

- Providing the measured amount of lubrication prevents wastage of lubricant.

- There is no climbing around machines or inaccessible areas (gases, exhaust gases, confined spaces, etc.) and therefore safety is improved.

- Reduces energy consumption due to less friction.

- Increases overall productivity resulting from increased machine availability and reduced downtime due to breakdowns or general maintenance.

There are several different types of automatic lubrication systems. The most commonly used systems are as follows.

(a) Single parallel line

(b) Double line parallel

(c) Single progressive line

(d) Mist lubrication

(e) Multiport direct lubricators.

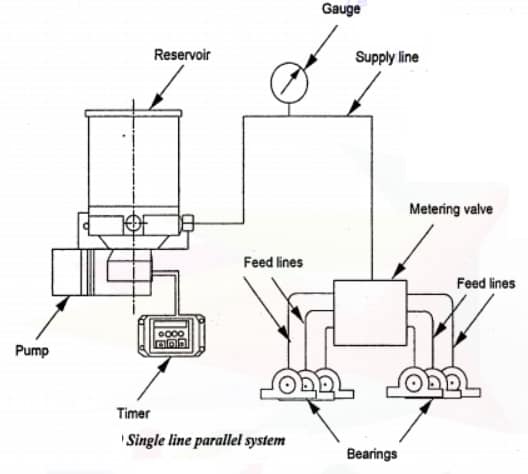

Single line parallel

A single-line parallel system can serve a single machine, different zones on a single machine, or even several separate machines and is ideal when the volume of lubricant varies for each point. In this type of system, a central pumping station automatically supplies lubricant

through a single supply line for several injector branches. Each injector serves a single lubrication point, operates independently and can be individually adjusted to deliver the desired amount of lubricant.

Operation begins when the controller/timer sends a signal to the pump starting the lubrication cycle. The pump begins pumping lubricant to increase pressure in the supply line that connects the pump to the injectors. Once the required pressure is reached, the lubricant injectors distribute a predetermined amount of lubricant to the lubrication points via supply lines. Once the entire system reaches the required pressure, a pressure switch will send a signal to the controller indicating that the grease has passed through all distribution points. The pump turns off. Pressure is released from the system and grease in the line is redirected back to the pump reservoir until normal system pressure level is restored.

single line parallel lubrication system

single line parallel lubrication systemBenefits

- It's easy to design.

- It is an easy and economical installation.

- It has individually adjustable injectors.

- It has proven a reliable design.

Disadvantages:

- May not be suitable for heavy lubricant combinations, cold temperatures, long supply lines between pumps and injectors.

Dual Line Parallel System:

A double-line parallel system is similar to a single-line parallel system. It uses hydraulic pressure to toggle adjustable valves to dispense measured doses of lubricant. It has 2 main supply lines that are alternatively used as pressure/ventilation lines. The advantage of a two-line system is that it can handle hundreds of lubrication points at several thousand feet using significantly smaller pipes. single pumping station

Operation begins when the controller/timer sends a signal to the pump to begin the lubrication cycle. The pump begins pumping lubricant to increase pressure in the first supply line (pressure) while simultaneously venting the second return line (vent). Once the

the required pressure is reached, a predetermined amount of lubricant is distributed by the dosing devices to half of the lubrication points via supply lines.

double line parallel lubrication system

double line parallel lubrication systemOnce the pressure switch monitors the main supply line pressure, indicating that a preset line pressure has been reached, the system is hydraulically closed. The controller turns off the pump and signals a switching valve to redirect the lubricant to the second main supply line. The next time the controller activates the system, the second main line will now become the pressure line, while the first line will become the vent line. The second line is pressurized and the entire process is repeated, lubricating the other lubrication points.

Benefits:

- Easily handles very viscous (heavy) greases.

- It can accommodate long supply lines between the pump and measuring devices.

Disadvantages:

- May not be the most cost-effective for smaller systems.

- Requires two supply lines (another cost).

Single line progressive system:

A single-line progressive system uses lubricant flow to cycle individual metering valves and valve assemblies. Valves consist of timing pistons moving back and forth in a specific bore. Each piston depends on flow from the previous piston to displace and displace lubricant. If one piston does not move, none of the following pistons will move. The valve output is not adjustable. Operation begins when the controller/timer sends a signal to the pump to begin the lubrication event. The pump then feeds the lubricant into the supply line that connects to the primary

metering valve for a pre-programmed period of time or for a number of times monitored via a designated piston cycle switch. The lubricant is fed to the various lubrication points, one after the other, through secondary progressive dosing valves sized for each series of

lubrication points and directly to each point through the supply lines.

single line progressive system

single line progressive systemBenefits:

- It accommodates a wide range of system control/monitoring options

- It can identify blockages by monitoring a single point.

Disadvantages:

- A blockage can disable the entire system

- Large systems may require complex piping.

(d) Mist lubrication:

Another simple system, mist lubrication facilitates low oil consumption and cool running bearings. The mist is generated with heat and/or air currents and is transported through the tube to the lubrication point with low pressure air. It is then sized to the appropriate drop before being dispensed into the bearing. Closed-loop systems are environmentally friendly because they return mist to the generator.

Benefits:

- It cools and lubricates the bearings

- Low pressure keeps pipe material cost low

- Positive pressure helps keep contaminants out of bearings.

Disadvantages:

- Environmental/health concerns arising from “stray fog” occur especially in open-loop systems

- It only handles oil

- It is highly sensitive to flow, viscosity and pressure variables

- There is an extra piping cost for closed loop systems.

(e) Multiport direct lubricators:

When the controller on the pump or external controller activates the drive motor, a set of cams rotates and activates individual injectors or pump elements to deliver a fixed amount of lubricant to each lubrication point. The systems are easy to design, direct the pump to the lubrication point without additional accessories, and are easy to troubleshoot.